- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ऑक्टोबर . 22, 2024 11:32 Back to list

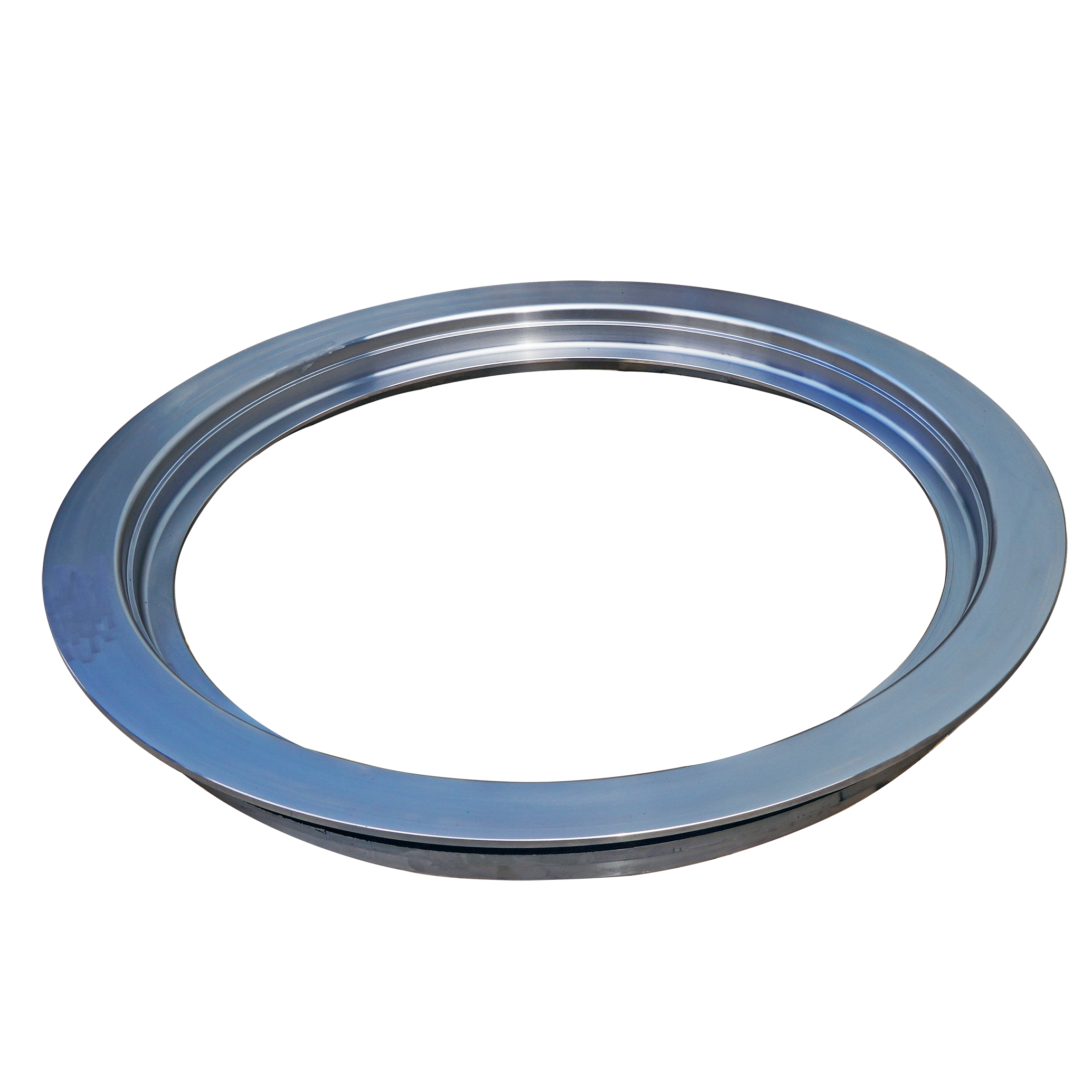

Superior Metal Sand Casting Solutions for High-Quality Manufacturing Excellence

High-Quality Metal Sand Casting A Comprehensive Overview

Metal sand casting is a time-honored manufacturing process that has remained integral to various industries due to its versatility and efficiency. This method, which involves pouring molten metal into a sand mold to create desired shapes, has gained prominence for producing high-quality components that meet complex specifications. This article explores the intricate world of high-quality metal sand casting, highlighting its processes, advantages, applications, and future trends.

At the core of metal sand casting lies the creation of a mold, typically made from a mixture of sand, clay, and water. The sand's ability to withstand high temperatures and its versatility in forming complex geometries make it an ideal material for molds. The process begins with the production of a pattern, which is usually made from metal or plastic. This pattern is used to create an impression in the sand, forming the cavity where the molten metal will be poured. The precision in crafting the pattern directly influences the final product's quality.

High-Quality Metal Sand Casting A Comprehensive Overview

The choice of metal also plays a significant role in determining the quality of the final casting. Common metals used in sand casting include iron, aluminum, brass, and steel, each offering distinct properties suited for various applications. For instance, aluminum castings are favored for their lightweight and corrosion-resistant properties, making them ideal for aerospace and automotive components. On the other hand, iron castings are often used in heavy machinery due to their strength and durability.

high quality metal sand casting

Quality assurance in sand casting is paramount. Techniques such as non-destructive testing (NDT) are employed to evaluate the integrity of the castings without compromising their usability. Methods like X-ray inspection and ultrasonic testing help identify internal flaws, ensuring that only components meeting stringent quality standards are dispatched for assembly. Such rigorous quality control measures are critical in industries where the reliability of components can significantly impact safety and performance.

The applications of high-quality metal sand casting are vast and varied, encompassing sectors such as automotive, aerospace, construction, and more. In automotive manufacturing, sand casting is instrumental in producing engine blocks, gearbox housings, and various other components that require precision and durability. Similarly, in the aerospace sector, the demand for lightweight yet robust materials makes sand casting an ideal choice for producing structural parts and engine components.

Looking to the future, the field of metal sand casting is poised for further innovation. The integration of advanced technologies such as 3D printing is revolutionizing mold production, allowing for more complex designs and reduced lead times. The advent of simulation software enables manufacturers to predict outcomes and optimize designs prior to the casting process, promoting efficiency and reducing waste.

In conclusion, high-quality metal sand casting remains a cornerstone of modern manufacturing, combining traditional techniques with innovative advancements to deliver reliable and precise components. As industries continue to evolve, the flexibility and adaptability of sand casting will ensure its relevance in meeting the diverse needs of tomorrow's technological landscape. By focusing on quality, precision, and innovation, the sand casting industry is well-equipped to face the challenges ahead, paving the way for an exciting future in metal manufacturing.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025