- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

सप्टेंबर . 25, 2024 18:55 Back to list

odm steel casting

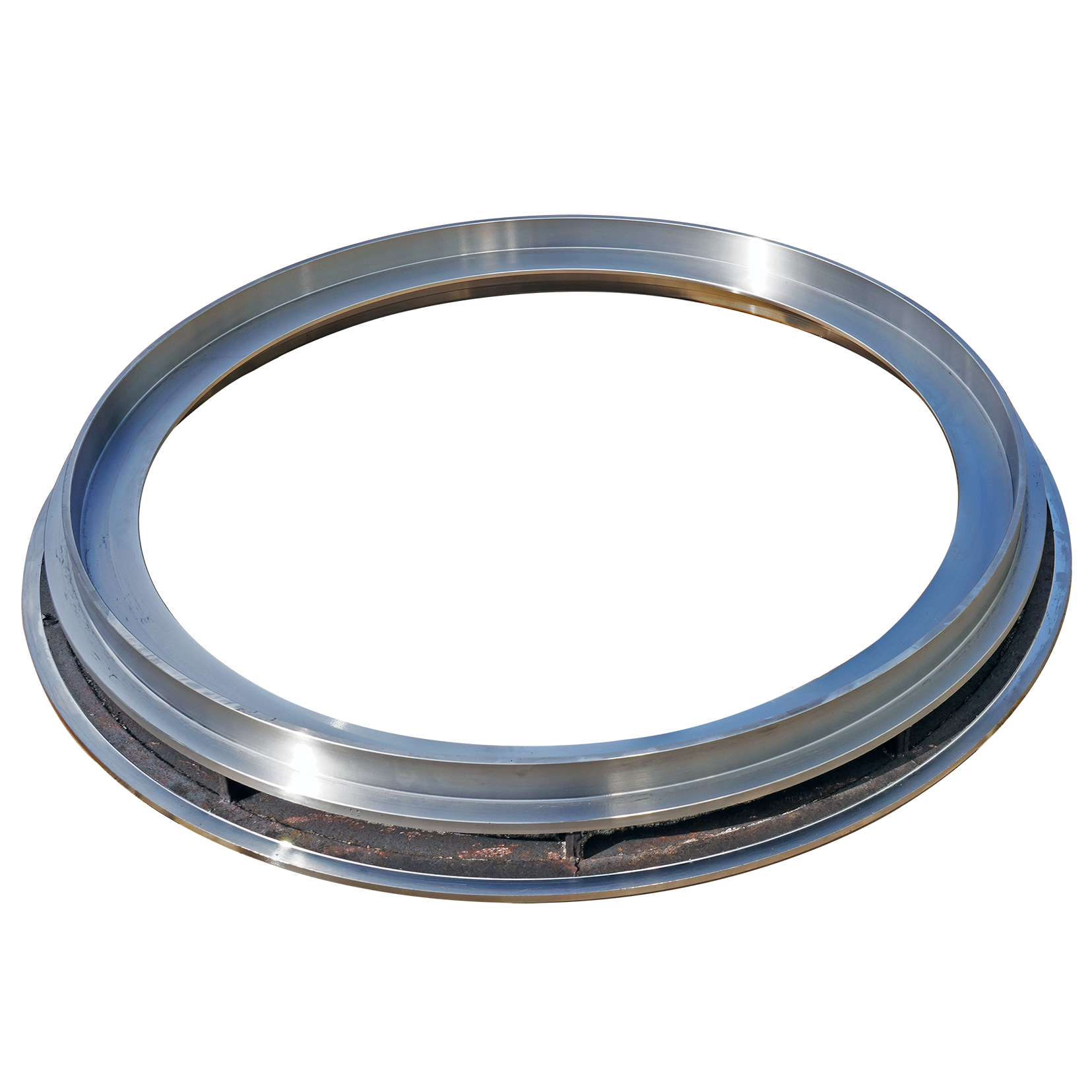

ODM Steel Casting Revolutionizing Manufacturing with Precision and Quality

In the ever-evolving world of manufacturing, the demand for precision and quality has never been more critical. One method that has gained significant traction is ODM (Original Design Manufacturer) steel casting, a process that combines sophisticated design with advanced manufacturing techniques to produce high-quality metal components for various industries.

What is ODM Steel Casting?

ODM steel casting refers to a manufacturing process where a company designs and produces steel castings based on the specific requirements of their clients. Unlike traditional manufacturing methods, which often produce standardized components, ODM allows for customized solutions tailored to meet precise specifications. This process not only enhances product performance but also enables manufacturers to reduce waste, improve efficiency, and ultimately lower production costs.

The Process of Steel Casting

The steel casting process involves several key steps. First, a detailed design is created, often using computer-aided design (CAD) software. This high level of detail ensures that every aspect of the component is meticulously crafted. Next, the mold is created, typically made from sand or metal, to form the shape of the final product.

Once the mold is prepared, molten steel is poured into it, allowing it to cool and solidify. After the casting has cooled, it is removed from the mold and undergoes a series of finishing processes, including machining, surface treatment, and inspection, to ensure it meets the desired specifications. This attention to detail is what sets ODM steel casting apart, as it allows for the production of highly complex shapes and designs that would be challenging to achieve through other methods.

Advantages of ODM Steel Casting

odm steel casting

1. Customization One of the primary advantages of ODM steel casting is its ability to produce customized solutions. Clients can specify exact designs, dimensions, and material properties, leading to products that fit their unique needs perfectly.

2. Quality and Precision With advanced technology and experienced professionals, ODM steel casting can achieve high levels of accuracy and surface finish, which are crucial for industries such as aerospace, automotive, and machinery manufacturing.

3. Cost-Effectiveness Though the initial design phase may require investment, the ability to produce high-quality components in bulk can lead to significant cost savings in the long run. Moreover, the reduction in waste and the optimization of production processes further contribute to lowered costs.

Applications Across Industries

The versatility of ODM steel casting allows it to be utilized across various industries. From heavy machinery and automotive components to intricate parts used in the aerospace sector, the applications are extensive. The ability to produce lightweight yet strong components makes it a preferred choice for sectors where performance and reliability are paramount.

Conclusion

In conclusion, ODM steel casting represents a significant advancement in manufacturing technology. Its focus on customization, quality, and cost-effectiveness makes it an attractive option for businesses aiming to enhance their product offerings. As industries continue to demand more specialized solutions, ODM steel casting is poised to play a pivotal role in shaping the future of manufacturing.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025