- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

डिसेंबर . 12, 2024 11:08 Back to list

oem milling frame casting

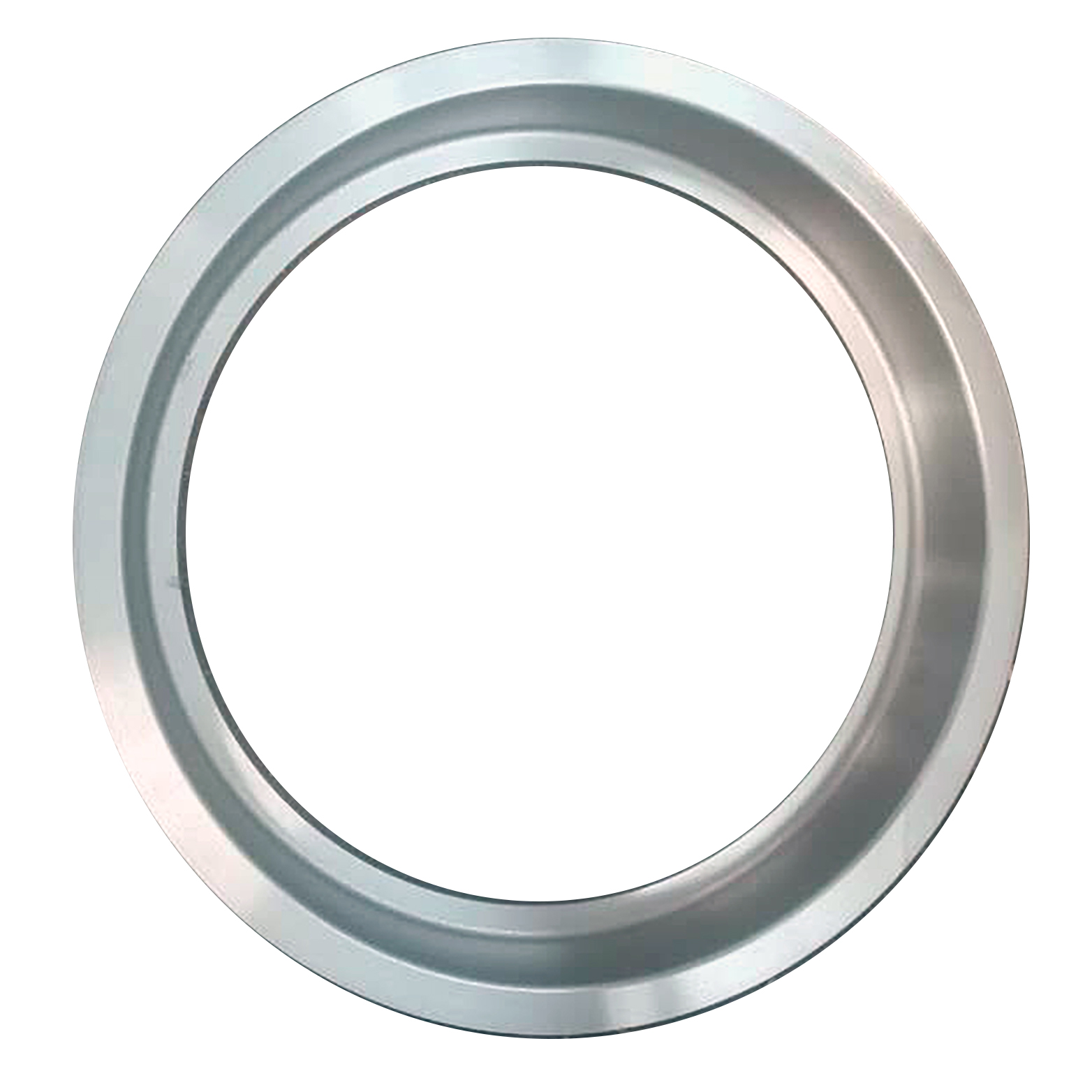

OEM Milling Frame Casting An Essential Component in Precision Engineering

In the realm of precision engineering and manufacturing, the significance of high-quality components cannot be overstated. One such integral component is the OEM (Original Equipment Manufacturer) milling frame casting. This specialized casting plays a pivotal role in the production of efficient and durable machinery, which is vital for various industries, including automotive, aerospace, and industrial machinery.

What is OEM Milling Frame Casting?

OEM milling frame casting refers to the process of creating a metal structure designed specifically for use in milling machines. The casting process involves pouring molten metal into a mold, where it cools and solidifies into the intended shape. This method allows for intricate designs and strong structural integrity, ideal for components subjected to rigorous operational demands.

The term OEM indicates that the parts are manufactured according to specific requirements set forth by a customer or a brand, ensuring compatibility and quality. This is particularly important in industries where precise specifications dictate the functionality and reliability of the final product.

Advantages of OEM Milling Frame Casting

1. Precision and Accuracy OEM milling frame castings are tailored to fit specific machinery needs and operational criteria, ensuring that they meet stringent quality control measures. The precision of these castings means that machinery operates smoothly, enhancing overall efficiency.

2. Durability Components made through the casting process possess high tensile strength and can withstand significant wear and tear. The materials used, typically high-quality alloys, ensure that these parts have a long operational life, which reduces the frequency of repairs and replacements.

3. Customization One of the standout features of OEM milling frame casting is the ability to customize designs. Manufacturers can create unique molds that cater to specific machine requirements, allowing companies to maximize their operational effectiveness.

oem milling frame casting

4. Cost-Effectiveness Although the initial investment in casting may appear high, the long-term savings on repairs, replacements, and operational downtime can be substantial. Tailored OEM castings can reduce excess material usage and waste in production, further contributing to cost-effectiveness.

5. Scalability OEM milled frame castings can be produced in large quantities, making it easier for manufacturers to scale their operations as demand increases. This adaptability is essential in industries that experience fluctuating market conditions.

Applications of OEM Milling Frame Casting

The applications of OEM milling frame castings are diverse. They are widely used in various sectors, including

- Automotive Industry Components such as engine blocks and transmission housings rely on precise milling frame castings to ensure performance and reliability in vehicles. - Aerospace Sector The aerospace industry demands exceptionally high standards for safety and performance, and OEM cast parts are crucial in manufacturing components that meet these rigorous requirements.

- Industrial Machinery From CNC (Computer Numerical Control) machines to heavy-duty equipment, milling frame castings provide the necessary backbone for many industrial applications.

Conclusion

In summary, OEM milling frame casting stands at the forefront of modern manufacturing, providing essential components that drive efficiency and performance across various industries. The benefits of precision, durability, customizable design, cost-effectiveness, and scalability make these castings indispensable for businesses aiming to maintain a competitive edge.

As industries continue to evolve and the demand for high-quality machinery increases, the significance of OEM milling frame castings will undoubtedly expand. Investing in these components not only ensures the longevity and reliability of machinery but also positions companies to meet future challenges head-on. The journey of innovation in manufacturing will largely depend on the quality and adaptability of these essential parts, ultimately shaping the landscape of precision engineering for years to come.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025