- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

डिसेंबर . 25, 2024 14:33 Back to list

Enhanced Efficiency in Tube-in-Tube Heat Exchangers for Optimized Energy Transfer

Understanding Tube-in-Tube Heat Exchangers A Comprehensive Overview

Heat exchangers play a crucial role in a variety of industrial applications, enabling efficient thermal energy transfer between two fluids. Among the various designs, the tube-in-tube heat exchanger stands out for its effectiveness and versatility. This article delves into the construction, working principle, advantages, and applications of tube-in-tube heat exchangers.

Construction and Working Principle

A tube-in-tube heat exchanger consists of two concentric tubes. The inner tube, which carries one fluid, is located inside the outer tube, which carries another fluid. The two fluids typically flow in opposite directions, a configuration known as counterflow, which enhances heat transfer efficiency.

When one of the fluids is heated, it transfers thermal energy to the colder fluid through the walls of the tubes. The design ensures that the surface area for heat exchange is maximized, allowing for effective thermal conduction. The length and diameter of the tubes can be adjusted based on the requirements of a specific application, making the design adaptable to various scenarios.

Advantages of Tube-in-Tube Heat Exchangers

1. High Efficiency The counterflow arrangement in tube-in-tube exchangers significantly improves the temperature gradient between the two fluids, leading to higher thermal efficiency. This configuration allows for a more effective heat transfer, often leading to compact designs that require less space.

tube in tube exchanger

3. Easier Maintenance The simple design of tube-in-tube exchangers facilitates easier cleaning and maintenance compared to more complex heat exchanger types. This aspect is particularly advantageous in industries where fouling is a concern, as the inner tubes can be easily accessed for cleaning.

4. Robustness These heat exchangers can withstand high pressures and temperatures, making them suitable for demanding applications. Their durable construction helps ensure longevity and reliability, which are critical attributes in industrial settings.

Applications

Tube-in-tube heat exchangers find applications across a range of industries, including chemical processing, food and beverage production, HVAC systems, and oil and gas refining. In the chemical industry, they are often used for heating and cooling processes, ensuring that temperature control is maintained for chemical reactions.

In the food industry, tube-in-tube heat exchangers play a vital role in pasteurization and sterilization processes, where precise temperature management is essential. The pharmaceutical industry also utilizes these exchangers for similar reasons, helping to maintain strict hygiene and temperature standards during drug production.

Moreover, the oil and gas sector employs tube-in-tube heat exchangers for cooling and heating crude oil, helping to enhance extraction and processing efficiency. Their robust construction makes them ideal for the challenging operating conditions typically found in this industry.

Conclusion

The tube-in-tube heat exchanger represents a sophisticated yet simple solution for efficient thermal energy transfer across various applications. Its compact design, coupled with high efficiency and ease of maintenance, makes it a favorable choice for many industries. As technological advancements continue to progress, the role of tube-in-tube heat exchangers is likely to expand, contributing further to energy efficiency and sustainability goals within the industrial sector. Understanding and leveraging the advantages of this type of heat exchanger can significantly enhance operational efficiency and effectiveness across numerous applications.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

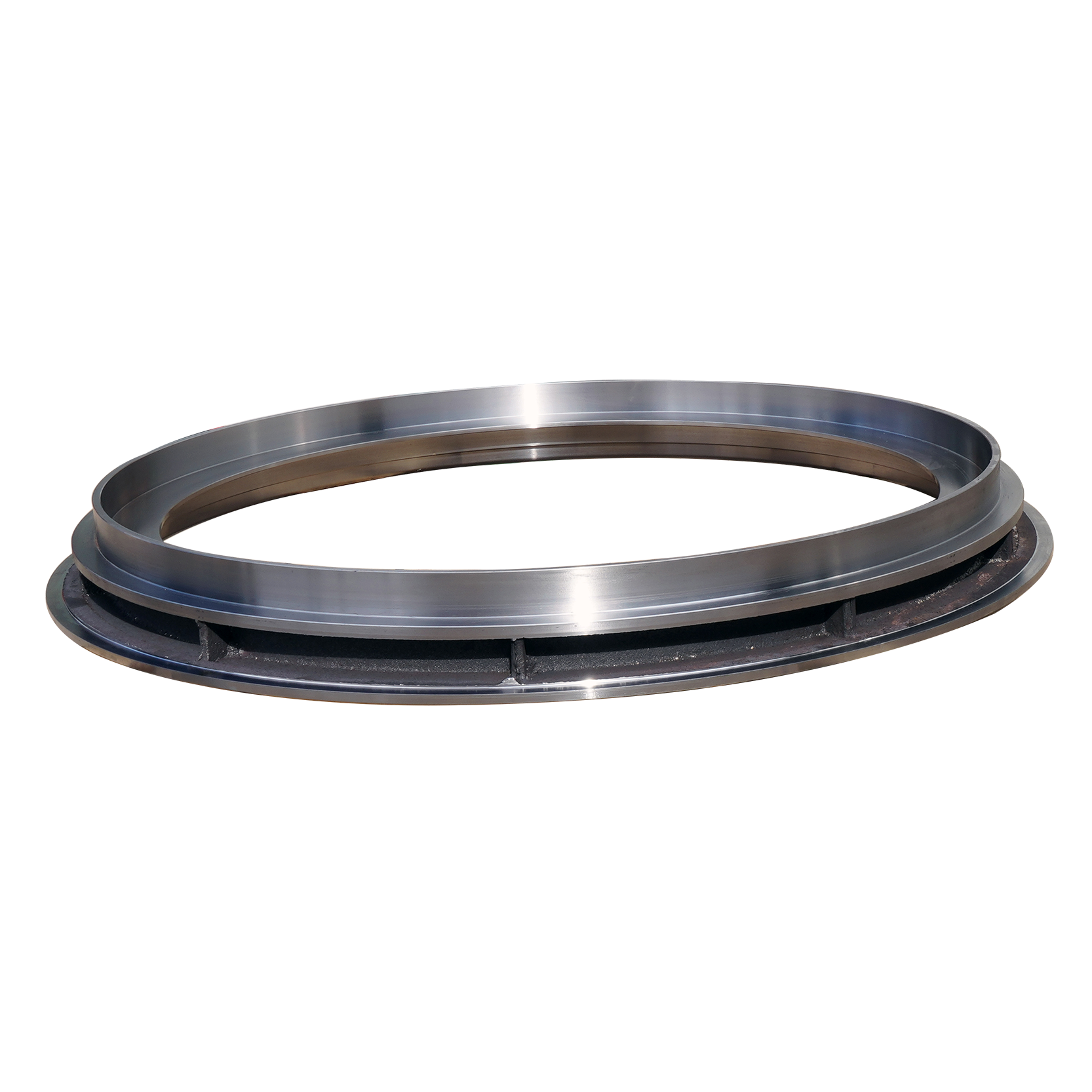

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025