- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Okt . 18, 2024 16:51 Back to list

Casting Iron Cements Pipe Mould Pallet Production Expert and Supplier Solutions

The Rise of Cast Iron Cement Pipe Mould Pallet Manufacturers

In the construction and infrastructure sectors, concrete pipes play a critical role in various applications, including drainage, sewage systems, and water supply. Among the important components in the production of these concrete pipes are the moulds and pallets used in their manufacturing process. As urbanization continues to surge and infrastructure needs expand, the demand for high-quality cast iron cement pipe moulds and pallets has seen a significant increase. This article aims to explore the role of cast iron cement pipe mould pallet manufacturers in meeting these demands.

Understanding the Industry

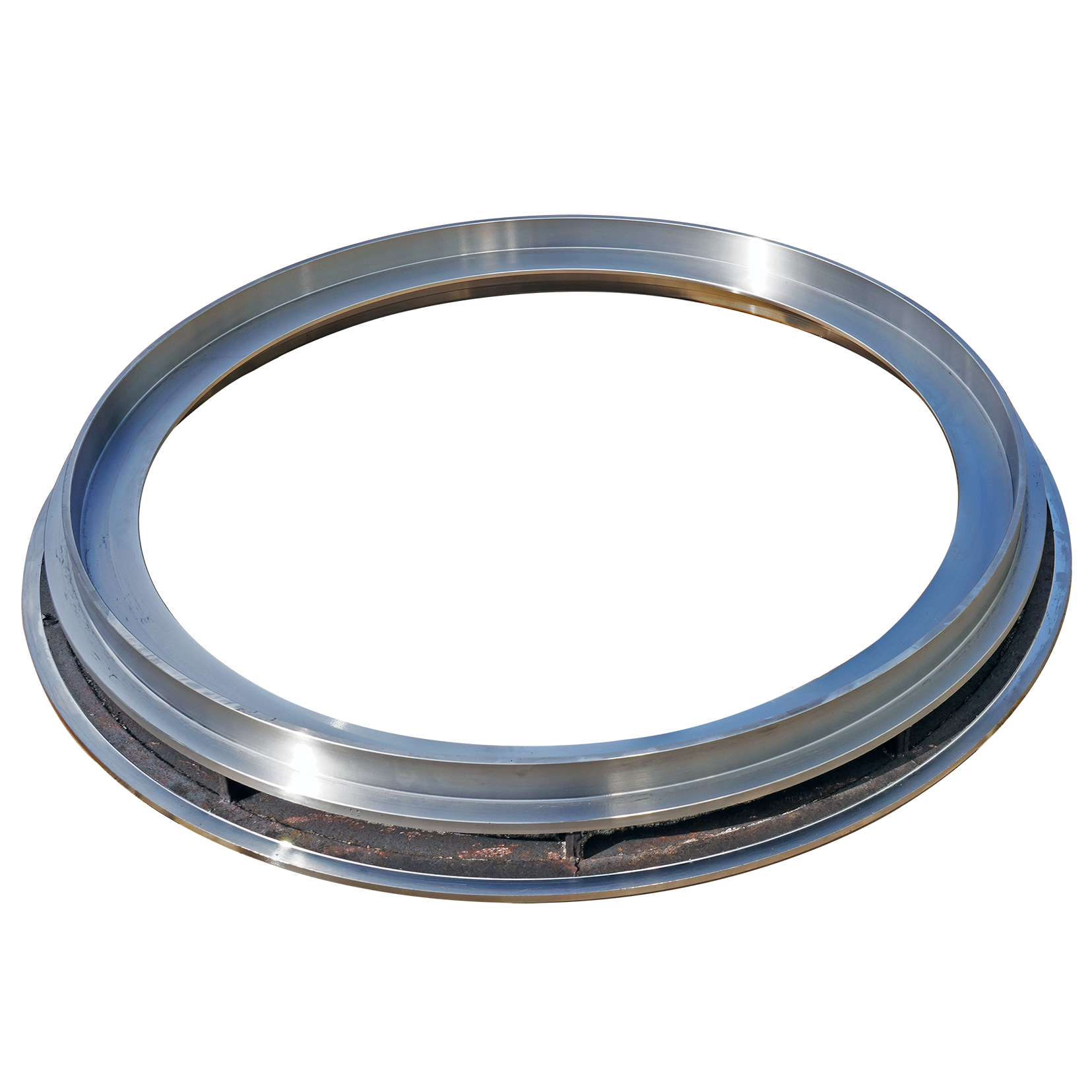

Cast iron cement pipe mould pallets are designed to create uniform, durable, and reliable concrete pipes. Moulds serve as the form in which concrete is poured and set, ensuring that the end products meet specific dimensional and structural requirements. The material used in these moulds, cast iron, is chosen for its strength, longevity, and ability to withstand harsh manufacturing conditions. Additionally, the pallets provide a sturdy base for the moulds during the curing process, further ensuring the integrity of the final product.

Manufacturers of these moulds and pallets must focus on several key areas quality materials, precision engineering, and innovative design. With the growing technological advancements in manufacturing processes, there is considerable pressure on these manufacturers to produce more efficient, cost-effective, and high-quality moulds.

The Benefits of Cast Iron Moulds

One of the main advantages of using cast iron for cement pipe moulds is its exceptional durability. Cast iron is resistant to wear and can withstand heavy loads, making it an ideal material for high-volume production environments. Additionally, cast iron’s thermal stability allows for better control over the curing process of concrete, thereby enhancing the quality of the pipes produced.

Another benefit is the ease of maintenance associated with cast iron moulds. Unlike other materials that may require frequent replacement due to wear and tear, cast iron can be maintained with proper care, leading to cost savings over time. Furthermore, cast iron’s non-stick properties often minimize the need for release agents, which can streamline the production process and reduce material costs.

cast iron cement pipe mould pallet manufacturer

Market Trends and Innovations

As the construction industry evolves, so do the needs and preferences of clients. In response, manufacturers are continuously adapting their products. There is a growing trend towards customisation and flexibility in mould design to meet specific project requirements. Advanced technologies, such as Computer-Aided Design (CAD) and precision cutting, allow manufacturers to create bespoke moulds that cater to individual client demands without compromising on quality.

Sustainability has also become a significant focus. Many manufacturers are now incorporating environmentally friendly practices in their production processes. This includes using recycled materials where possible and adopting less energy-intensive manufacturing methods. Such initiatives not only reduce the environmental footprint but also appeal to the growing market of eco-conscious consumers.

Challenges Faced by Manufacturers

Despite the positive outlook and growth potential, cast iron cement pipe mould pallet manufacturers face several challenges. The fluctuating prices of raw materials can impact production costs and profitability. Additionally, maintaining high-quality standards while meeting increasing demands can strain manufacturing capacities. There is a continuous need for investment in technology and workforce training to enhance operational efficiency.

Moreover, competition in the industry is fierce, with both local and international players vying for market share. Manufacturers must differentiate themselves through innovation, quality, and customer service to remain competitive.

Conclusion

In conclusion, cast iron cement pipe mould pallet manufacturers play an essential role in the construction and infrastructure sectors. As the demand for durable and reliable concrete pipes increases, so does the importance of high-quality moulds and pallets. By focusing on innovation, sustainability, and customer-centric approaches, these manufacturers can successfully navigate challenges and contribute to the development of resilient infrastructure worldwide. Their ability to adapt to changing market dynamics will determine their success as they move forward in an increasingly competitive landscape.

-

Precision Silica Sol Casting Solutions Custom & ODM Options

NewsJun.06,2025

-

Top Quality Steel Castings Manufacturer Wholesale Deals

NewsJun.06,2025

-

Custom Heat Exchangers for Low NOx Gas Boilers Cast Silico Al

NewsJun.06,2025

-

Custom Punch Concrete Pipe Mold Bottom Ring Precision & Durability

NewsJun.06,2025

-

Precision Water Glass Sand Casting Services Custom & Durable

NewsJun.06,2025

-

Precision nvestment Casting Parts Buy Custom Solutions

NewsJun.05,2025