- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 05, 2024 09:13 Back to list

gray iron casting suppliers

Gray Iron Casting Suppliers A Key to Quality Manufacturing

Gray iron casting is a crucial component in various industries, providing a blend of strength, wear resistance, and excellent machinability. As one of the most widely used cast iron types, gray iron is favored for its remarkable characteristics, particularly in the production of engine blocks, crankshafts, and various machinery parts. To ensure quality and reliability in products, it is vital to choose the right gray iron casting suppliers.

Gray Iron Casting Suppliers A Key to Quality Manufacturing

Furthermore, the capabilities of the supplier play a significant role. Look for suppliers that offer a wide range of gray iron grades to meet specific engineering requirements. Each grade, characterized by its microstructure and mechanical properties, serves different applications. A supplier who understands these distinctions and can recommend the appropriate grade for your needs adds significant value to the procurement process.

gray iron casting suppliers

Quality assurance practices also differentiate reputable suppliers from their competitors. Verify that the supplier adheres to recognized quality standards, such as those set by the International Organization for Standardization (ISO). Quality control measures should include inspection protocols during the casting process, ensuring defects are minimized and the final products meet stringent specifications.

In addition to quality and capability, responsiveness and customer service are critical. A supplier that actively communicates and collaborates with clients can help troubleshoot issues, offer insights into design improvements, and ensure timely delivery. Strong customer service creates a partnership that extends beyond mere transactions, fostering a relationship that contributes to the success of both parties.

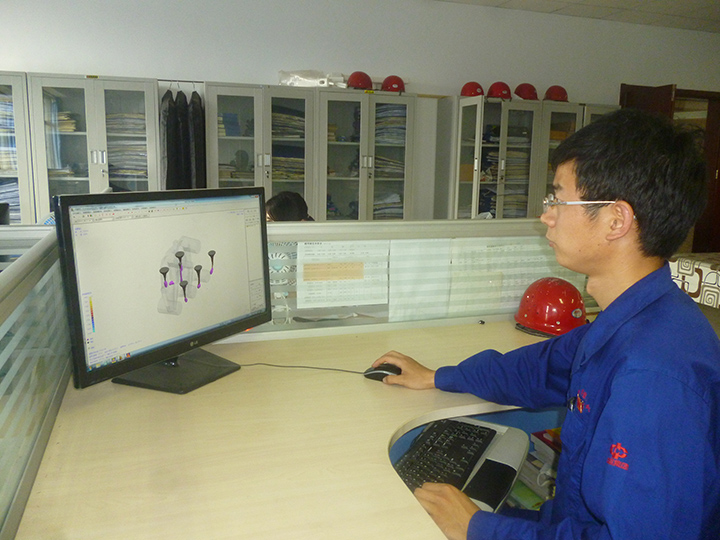

Finally, consider the supplier’s technological capabilities. Suppliers that invest in modern technology and equipment can produce intricate designs and complex shapes more efficiently. Automation and computer-aided design (CAD) tools can enhance accuracy and reduce lead times, allowing manufacturers to respond swiftly to market demands.

In conclusion, selecting the right gray iron casting supplier is fundamental to achieving quality and efficiency in manufacturing processes. By considering factors such as experience, product variety, quality control, customer service, and technological capabilities, companies can forge lasting partnerships that drive success and innovation in their respective industries.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025