- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

डिस . 28, 2024 00:54 Back to list

cast aluminum silicon radiator casting exporter

The Export Landscape of Cast Aluminum Silicon Radiator Castings

In recent years, the automotive and industrial sectors have experienced a significant shift toward lightweight materials, driven by the demands for fuel efficiency and sustainability. Among various materials, cast aluminum silicon alloys have emerged as a preferred choice for radiator manufacturing, particularly in the automotive sector. Their remarkable properties, such as excellent thermal conductivity, low weight, and resistance to corrosion, make them ideal for high-performance applications. As global markets expand, the export of cast aluminum silicon radiator castings is becoming increasingly pivotal.

The Importance of Cast Aluminum Silicon Alloys

Cast aluminum silicon alloys are known for their superior characteristics, which include enhanced fluidity during the casting process, improved mechanical properties, and reduced thermal expansion. These attributes make them especially suitable for components that require high performance and durability under extreme conditions. Radiators, in particular, benefit from these features, as they must efficiently dissipate heat while being subjected to various environmental factors.

Key Players in the Export Market

Countries with advanced manufacturing capabilities, such as China, Germany, and the United States, are leading exporters of cast aluminum silicon radiator castings. These countries possess a robust industrial infrastructure, skilled labor, and access to the latest technological advancements. China, for instance, has become a dominant player in the aluminum casting industry, leveraging its cost-effective production capabilities and vast supply chains. Meanwhile, European countries are known for their quality manufacturing standards and precision engineering, appealing to markets that prioritize high-quality components.

Market Trends and Demand

The global demand for cast aluminum silicon radiator castings is witnessing a steady increase, driven by several factors. Firstly, the automotive industry is undergoing a significant transformation towards electric vehicles (EVs), which require efficient cooling systems to manage heat generated by batteries and electronics. This trend has led to increased investment in lightweight materials, including cast aluminum silicon alloys, to enhance performance and energy efficiency.

cast aluminum silicon radiator casting exporter

Secondly, the industrial sector, particularly in manufacturing processes that involve heat exchangers and cooling systems, is also contributing to the demand for high-quality radiator castings. These sectors are increasingly adopting aluminum-based solutions due to their environmental benefits and recyclability, aligning with global sustainability goals.

Challenges in the Export Market

Despite the positive outlook, there are several challenges faced by exporters of cast aluminum silicon radiator castings. Regulatory requirements and trade tariffs can significantly impact export operations, leading to increased costs and logistical complexities. Additionally, competition from other materials, such as plastic and copper, poses a threat to the market share of aluminum castings. Companies need to continuously innovate and improve their product offerings to maintain their competitive advantage.

Furthermore, supply chain disruptions, which have been exacerbated by global events such as the COVID-19 pandemic, can affect production timelines and delivery schedules. Manufacturers are now more focused on building resilient supply chains and diversifying their sourcing strategies to mitigate risks.

The Future Outlook

Looking ahead, the export market for cast aluminum silicon radiator castings is poised for continued growth. The increasing emphasis on lightweight, fuel-efficient vehicles, as well as the rise of EVs, will likely sustain demand for high-performance aluminum castings. Innovations in manufacturing processes, such as additive manufacturing and advancements in alloy compositions, will further enhance the appeal of these materials.

In conclusion, as the world continues to embrace sustainability and efficiency, the export of cast aluminum silicon radiator castings will play a crucial role in meeting the needs of modern industries. Key players in this market must navigate challenges and leverage opportunities to ensure they remain at the forefront of this evolving landscape.

-

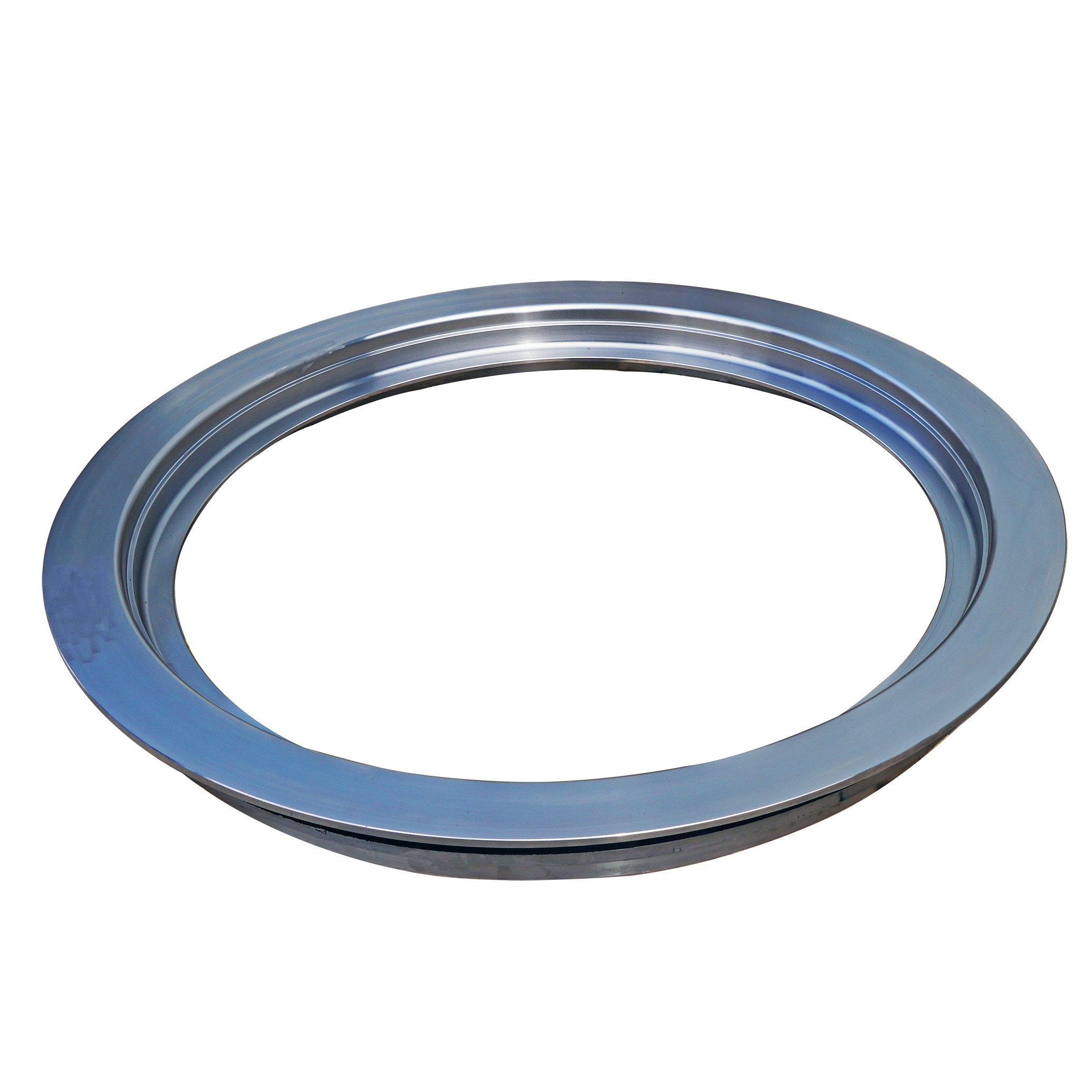

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025