- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 26, 2024 05:08 Back to list

3. Automated Aluminum Molding System

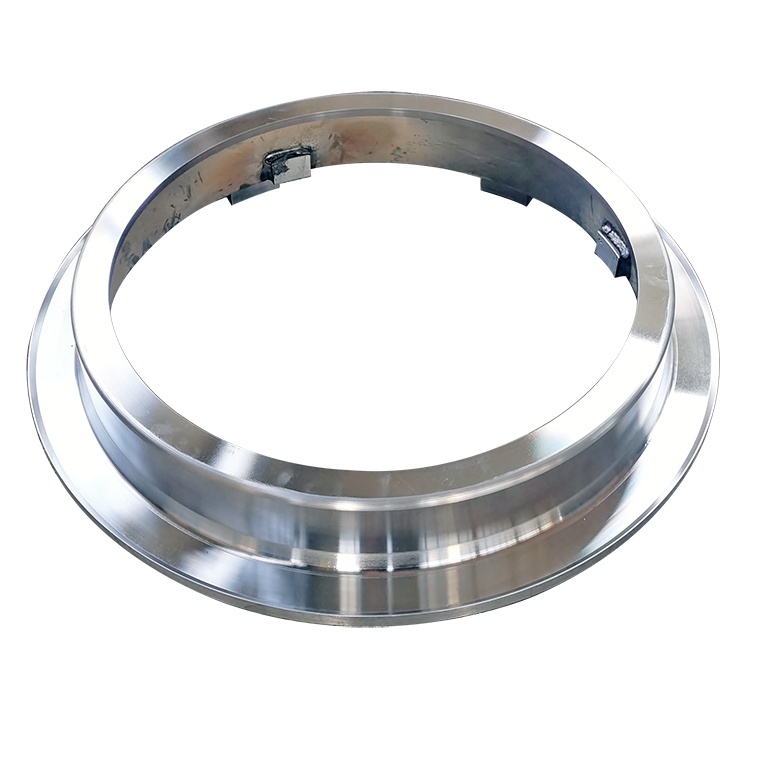

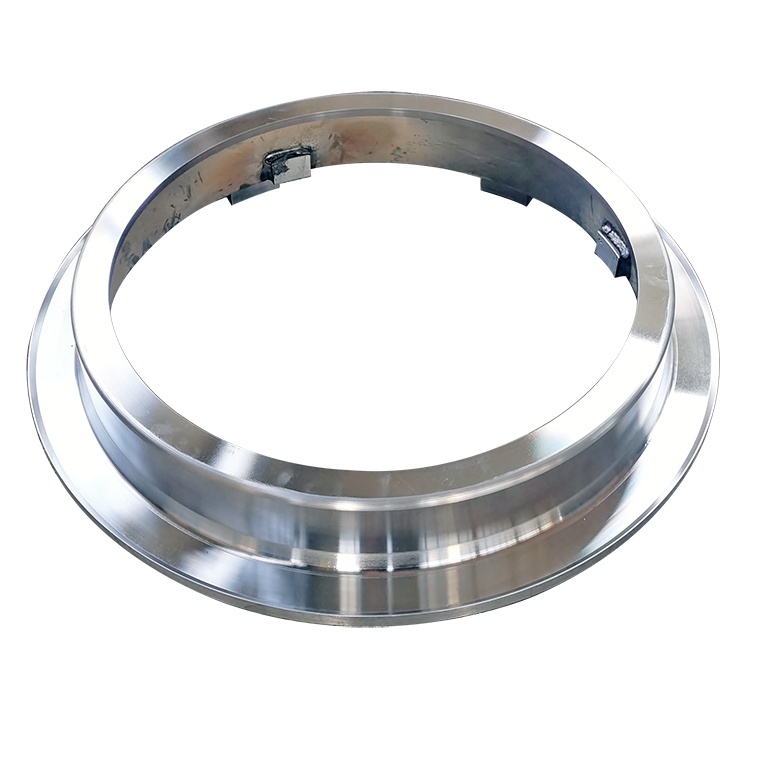

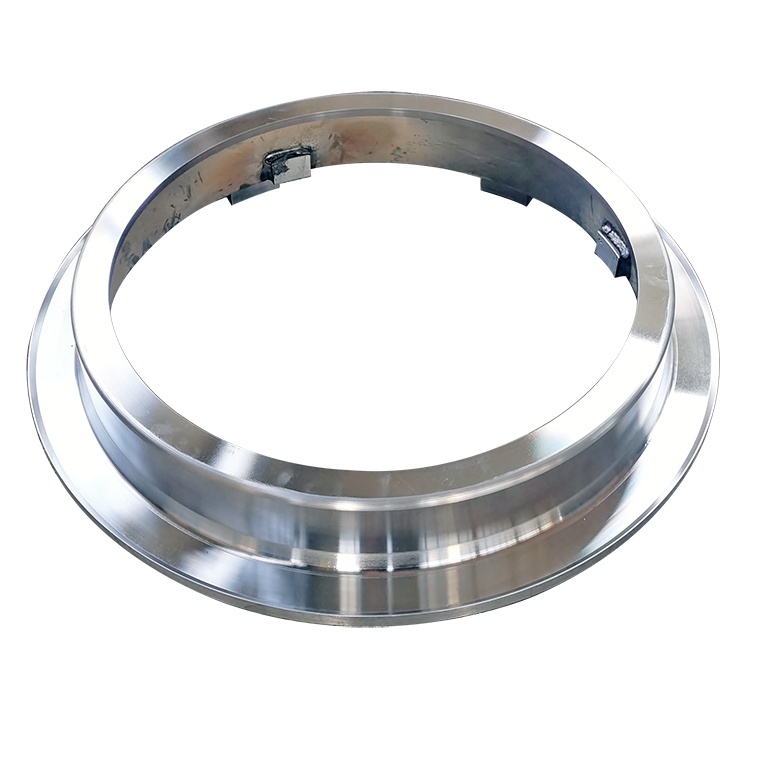

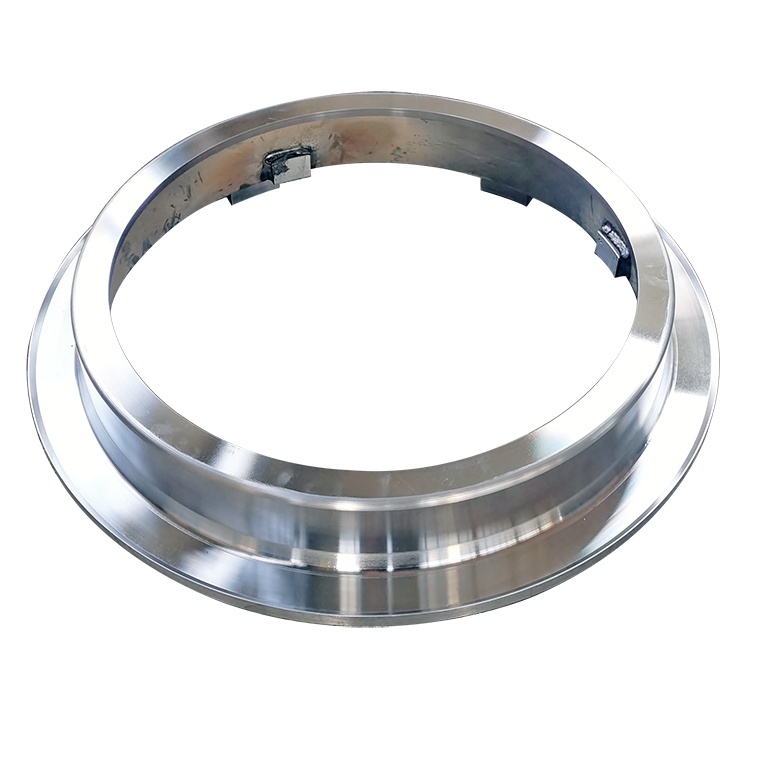

Aluminium Molding Machines Revolutionizing Manufacturing Processes

In the realm of manufacturing, aluminium molding machines have emerged as game-changers, offering unparalleled efficiency, precision, and versatility. These advanced tools have revolutionized the way businesses produce a wide range of products, from intricate automotive components to consumer electronics.

One of the key advantages of aluminium molding machines is their ability to process a diverse array of materials, including not only aluminium but also other metals and plastics. This versatility allows manufacturers to create complex shapes and structures that would be difficult or impossible using traditional manufacturing techniques.

Another significant advantage of these machines is their high speed and accuracy. Aluminium molding machines can operate at speeds that are up to 10 times faster than manual processes, resulting in significant time and cost savings. Moreover, these machines are equipped with advanced sensors and controls that ensure precise and consistent results, even in the most demanding applications.

In addition to their speed and accuracy, aluminium molding machines offer excellent repeatability. This means that they can produce identical parts time and time again, without any variation in quality This means that they can produce identical parts time and time again, without any variation in quality This means that they can produce identical parts time and time again, without any variation in quality This means that they can produce identical parts time and time again, without any variation in quality

This means that they can produce identical parts time and time again, without any variation in quality This means that they can produce identical parts time and time again, without any variation in quality aluminium molding machine. This is particularly important in industries where consistency is critical, such as aerospace and medical devices.

Perhaps one of the most significant benefits of aluminium molding machines is their ability to produce parts with complex geometries and intricate details. These machines use advanced hydraulic systems and computer-controlled motions to create parts with thin walls, deep draws, and other challenging features. As a result, manufacturers can produce parts that were previously unattainable using traditional manufacturing techniques.

Overall, aluminium molding machines have become indispensable tools for manufacturers seeking to improve efficiency, reduce costs, and enhance product quality. Their versatility, speed, accuracy, repeatability, and ability to produce complex parts make them an ideal choice for a wide range of applications. As technology continues to advance, we can expect to see even more innovative uses of these remarkable machines in the years ahead.

aluminium molding machine. This is particularly important in industries where consistency is critical, such as aerospace and medical devices.

Perhaps one of the most significant benefits of aluminium molding machines is their ability to produce parts with complex geometries and intricate details. These machines use advanced hydraulic systems and computer-controlled motions to create parts with thin walls, deep draws, and other challenging features. As a result, manufacturers can produce parts that were previously unattainable using traditional manufacturing techniques.

Overall, aluminium molding machines have become indispensable tools for manufacturers seeking to improve efficiency, reduce costs, and enhance product quality. Their versatility, speed, accuracy, repeatability, and ability to produce complex parts make them an ideal choice for a wide range of applications. As technology continues to advance, we can expect to see even more innovative uses of these remarkable machines in the years ahead.

This means that they can produce identical parts time and time again, without any variation in quality This means that they can produce identical parts time and time again, without any variation in quality

This means that they can produce identical parts time and time again, without any variation in quality This means that they can produce identical parts time and time again, without any variation in quality aluminium molding machine. This is particularly important in industries where consistency is critical, such as aerospace and medical devices.

Perhaps one of the most significant benefits of aluminium molding machines is their ability to produce parts with complex geometries and intricate details. These machines use advanced hydraulic systems and computer-controlled motions to create parts with thin walls, deep draws, and other challenging features. As a result, manufacturers can produce parts that were previously unattainable using traditional manufacturing techniques.

Overall, aluminium molding machines have become indispensable tools for manufacturers seeking to improve efficiency, reduce costs, and enhance product quality. Their versatility, speed, accuracy, repeatability, and ability to produce complex parts make them an ideal choice for a wide range of applications. As technology continues to advance, we can expect to see even more innovative uses of these remarkable machines in the years ahead.

aluminium molding machine. This is particularly important in industries where consistency is critical, such as aerospace and medical devices.

Perhaps one of the most significant benefits of aluminium molding machines is their ability to produce parts with complex geometries and intricate details. These machines use advanced hydraulic systems and computer-controlled motions to create parts with thin walls, deep draws, and other challenging features. As a result, manufacturers can produce parts that were previously unattainable using traditional manufacturing techniques.

Overall, aluminium molding machines have become indispensable tools for manufacturers seeking to improve efficiency, reduce costs, and enhance product quality. Their versatility, speed, accuracy, repeatability, and ability to produce complex parts make them an ideal choice for a wide range of applications. As technology continues to advance, we can expect to see even more innovative uses of these remarkable machines in the years ahead. Share

Pervious:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025