- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 15, 2024 19:48 Back to list

Aluminum casting process is discussed.

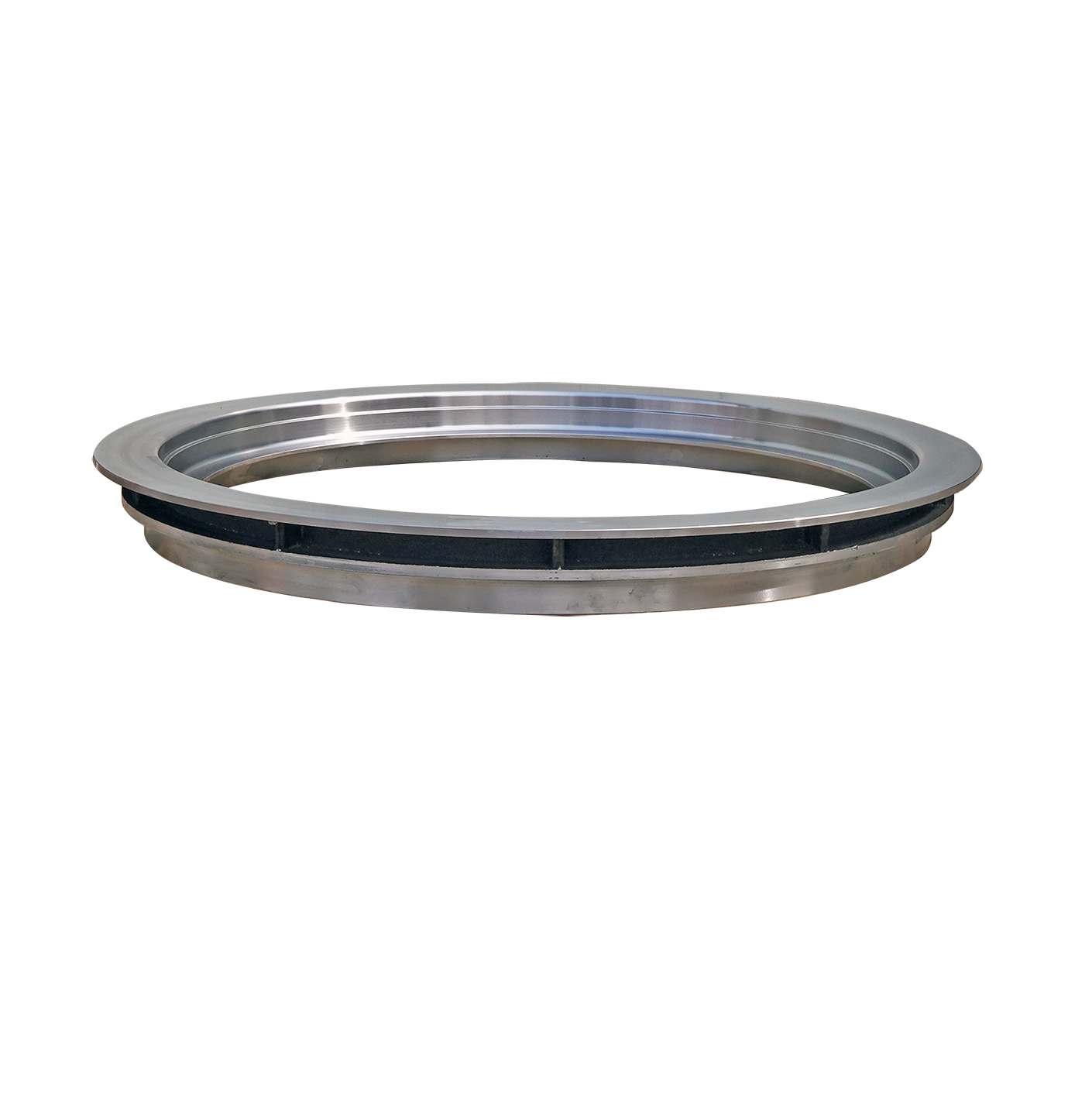

Die casting is a manufacturing process that involves injecting molten metal under high pressure into a mold cavity. Aluminum, being lightweight, strong, and resistant to corrosion, is an ideal material for this process. In this article, we will discuss the benefits of die casting aluminum.

Firstly, die casting aluminum offers excellent dimensional accuracy and stability. The process allows for tight tolerances and complex shapes, making it suitable for producing intricate parts with precise specifications. This makes it ideal for industries such as automotive, aerospace, and electronics where precision is critical.

Secondly, die casting aluminum provides superior strength and durability. The high-pressure injection process ensures that the aluminum fills every crevice of the mold, resulting in a part with minimal porosity and voids. This leads to a stronger final product that can withstand harsh environments and extreme temperatures.

Thirdly, die casting aluminum offers significant weight savings compared to other materials such as steel or iron. This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount

This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount die casting aluminum.

Fourthly, die casting aluminum is cost-effective. The process has a high production rate, which means that large quantities of parts can be produced quickly and efficiently. Additionally, the tooling used in die casting is durable and long-lasting, reducing the need for frequent replacements and maintenance costs.

Fifthly, die casting aluminum is environmentally friendly. Aluminum is 100% recyclable, meaning that scrapped or defective parts can be remelted and reused in future projects without any loss in quality or performance. This reduces waste and conserves resources, making it an eco-friendly option for manufacturers.

In conclusion, die casting aluminum offers numerous benefits over other materials and manufacturing processes. Its precision, strength, weight savings, cost-effectiveness, and environmental friendliness make it a popular choice for various industries worldwide. As technology continues to advance, we can expect even more innovations in die casting aluminum, further expanding its applications and benefits.

die casting aluminum.

Fourthly, die casting aluminum is cost-effective. The process has a high production rate, which means that large quantities of parts can be produced quickly and efficiently. Additionally, the tooling used in die casting is durable and long-lasting, reducing the need for frequent replacements and maintenance costs.

Fifthly, die casting aluminum is environmentally friendly. Aluminum is 100% recyclable, meaning that scrapped or defective parts can be remelted and reused in future projects without any loss in quality or performance. This reduces waste and conserves resources, making it an eco-friendly option for manufacturers.

In conclusion, die casting aluminum offers numerous benefits over other materials and manufacturing processes. Its precision, strength, weight savings, cost-effectiveness, and environmental friendliness make it a popular choice for various industries worldwide. As technology continues to advance, we can expect even more innovations in die casting aluminum, further expanding its applications and benefits.

This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount

This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount This makes it an attractive option for applications where weight reduction is crucial, such as in the automotive industry where fuel efficiency is paramount die casting aluminum.

Fourthly, die casting aluminum is cost-effective. The process has a high production rate, which means that large quantities of parts can be produced quickly and efficiently. Additionally, the tooling used in die casting is durable and long-lasting, reducing the need for frequent replacements and maintenance costs.

Fifthly, die casting aluminum is environmentally friendly. Aluminum is 100% recyclable, meaning that scrapped or defective parts can be remelted and reused in future projects without any loss in quality or performance. This reduces waste and conserves resources, making it an eco-friendly option for manufacturers.

In conclusion, die casting aluminum offers numerous benefits over other materials and manufacturing processes. Its precision, strength, weight savings, cost-effectiveness, and environmental friendliness make it a popular choice for various industries worldwide. As technology continues to advance, we can expect even more innovations in die casting aluminum, further expanding its applications and benefits.

die casting aluminum.

Fourthly, die casting aluminum is cost-effective. The process has a high production rate, which means that large quantities of parts can be produced quickly and efficiently. Additionally, the tooling used in die casting is durable and long-lasting, reducing the need for frequent replacements and maintenance costs.

Fifthly, die casting aluminum is environmentally friendly. Aluminum is 100% recyclable, meaning that scrapped or defective parts can be remelted and reused in future projects without any loss in quality or performance. This reduces waste and conserves resources, making it an eco-friendly option for manufacturers.

In conclusion, die casting aluminum offers numerous benefits over other materials and manufacturing processes. Its precision, strength, weight savings, cost-effectiveness, and environmental friendliness make it a popular choice for various industries worldwide. As technology continues to advance, we can expect even more innovations in die casting aluminum, further expanding its applications and benefits. Share

Pervious:

Latest news

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025