- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 20, 2024 07:05 Back to list

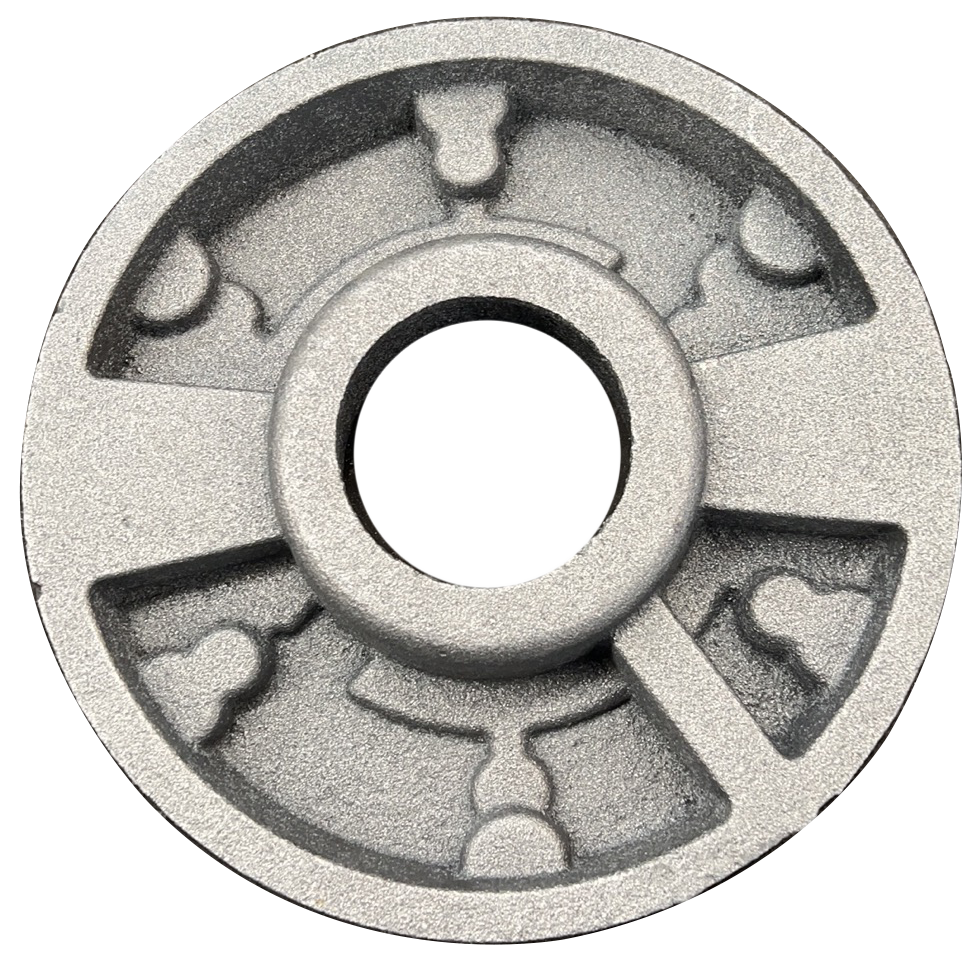

aluminum alloys casting

The Importance of Aluminum Alloys in Casting

Aluminum alloys have become a cornerstone in the manufacturing industry, particularly in casting applications due to their remarkable properties such as low density, excellent corrosion resistance, and good mechanical strength. These attributes not only enhance the performance of products made from aluminum alloys but also contribute to their versatility in various sectors, including automotive, aerospace, and consumer goods.

The Importance of Aluminum Alloys in Casting

Moreover, aluminum alloys exhibit excellent corrosion resistance, thanks to the natural oxide layer that forms on their surface upon exposure to air. This characteristic is particularly beneficial for products that are used in harsh environments, such as marine applications or components exposed to chemicals. Additionally, the recyclability of aluminum makes it an environmentally friendly choice. It requires significantly less energy to recycle aluminum than to produce it from raw materials, thus promoting sustainability within the industry.

aluminum alloys casting

The casting process for aluminum alloys can be categorized into various methods, including sand casting, die casting, and investment casting. Each method has its own set of advantages and is chosen based on the specific requirements of the component being manufactured. For example, die casting allows for high-volume production of complex shapes with excellent surface finishes and tight tolerances, making it ideal for mass-produced items like automotive parts and consumer electronics.

Certain aluminum alloys are specifically formulated to enhance their casting properties. For instance, the 356 alloy is commonly used in sand and die casting due to its excellent fluidity and resistance to thermal cracking. This alloy provides a balance of strength and ductility, making it suitable for a wide range of applications. Another popular choice is the A380 alloy, prized for its ability to cast intricate designs and superior mechanical properties, particularly in high-strength applications.

The advancements in casting technologies have also revolutionized the production of aluminum components. Innovations such as computer-aided design (CAD) and computer-aided manufacturing (CAM) have streamlined the design and production processes, resulting in greater efficiency and reduced lead times. Additionally, the integration of 3D printing technologies is beginning to complement traditional casting methods, allowing for rapid prototyping and the creation of complex geometries that were previously difficult or impossible to achieve.

In conclusion, aluminum alloys have established themselves as a vital material in the casting industry. Their lightweight, corrosion-resistant, and recyclable nature, combined with advanced casting techniques, makes them an ideal choice for a plethora of applications across various sectors. As the demand for more sustainable and efficient materials continues to rise, aluminum alloys are likely to remain at the forefront of innovation in casting, driving advancements in performance and sustainability. The future of manufacturing will undoubtedly see an even greater reliance on these versatile materials, which will continue to shape the landscape of industries worldwide.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025