- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 03, 2024 09:28 Back to list

aluminum die casting factory

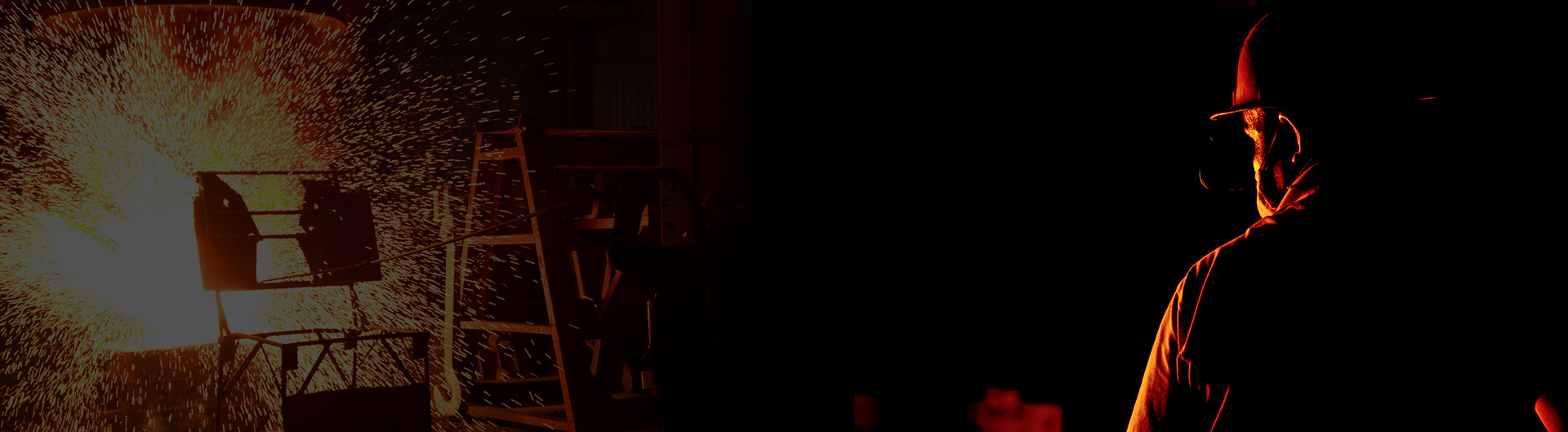

Aluminum Die Casting Factory Innovation and Efficiency in Metal Manufacturing

Aluminum die casting has emerged as a pivotal process in the manufacturing industry, offering a streamlined method for producing complex metal components with precision and efficiency

. An aluminum die casting factory exemplifies this innovative approach, combining state-of-the-art technology with skilled craftsmanship to meet the needs of various sectors, including automotive, aerospace, and consumer electronics.The process of aluminum die casting begins with the melting of aluminum alloy at high temperatures, typically around 700 degrees Celsius. Once melted, the molten aluminum is injected into a steel die under high pressure. This technique allows for the creation of intricate parts with tight tolerances, ensuring that each component meets the exact specifications required by clients. The use of aluminum, known for its lightweight and corrosion-resistant properties, makes it an ideal choice for industries looking for durable yet lightweight solutions.

One of the critical advantages of an aluminum die casting factory is its ability to produce high volumes of parts quickly and consistently. Automated machinery and advanced robotics play a significant role in enhancing productivity while maintaining quality standards. Modern factories are equipped with computer numerical control (CNC) systems that streamline machining processes, reducing human error and increasing efficiency.

aluminum die casting factory

Moreover, the sustainability of aluminum die casting cannot be overlooked. Aluminum is 100% recyclable, and the processes implemented in modern factories focus on minimizing waste and energy consumption. Reusing aluminum scrap not only lowers production costs but also contributes to environmental preservation. Many factories are now adopting green practices, incorporating energy-efficient machinery and utilizing renewable energy sources.

The versatility of aluminum die casting also means that factories can cater to a diverse range of applications. From engine blocks and transmission housings in the automotive sector to intricate components in electronic devices, the possibilities are virtually limitless. This adaptability, coupled with the ability to deliver high-quality parts at competitive prices, positions aluminum die casting factories as leaders in the manufacturing landscape.

In conclusion, aluminum die casting factories represent the intersection of technology, efficiency, and sustainability in modern manufacturing. By harnessing the advantages of aluminum and refining casting techniques, these factories play a crucial role in producing components that meet the evolving demands of today's industries, driving innovation and supporting economic growth. As technology continues to advance, the future of aluminum die casting looks promising, paving the way for even greater achievements in manufacturing excellence.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025