- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 08, 2024 03:00 Back to list

Advantages and Techniques of Aluminum Mold Casting in Modern Manufacturing Processes

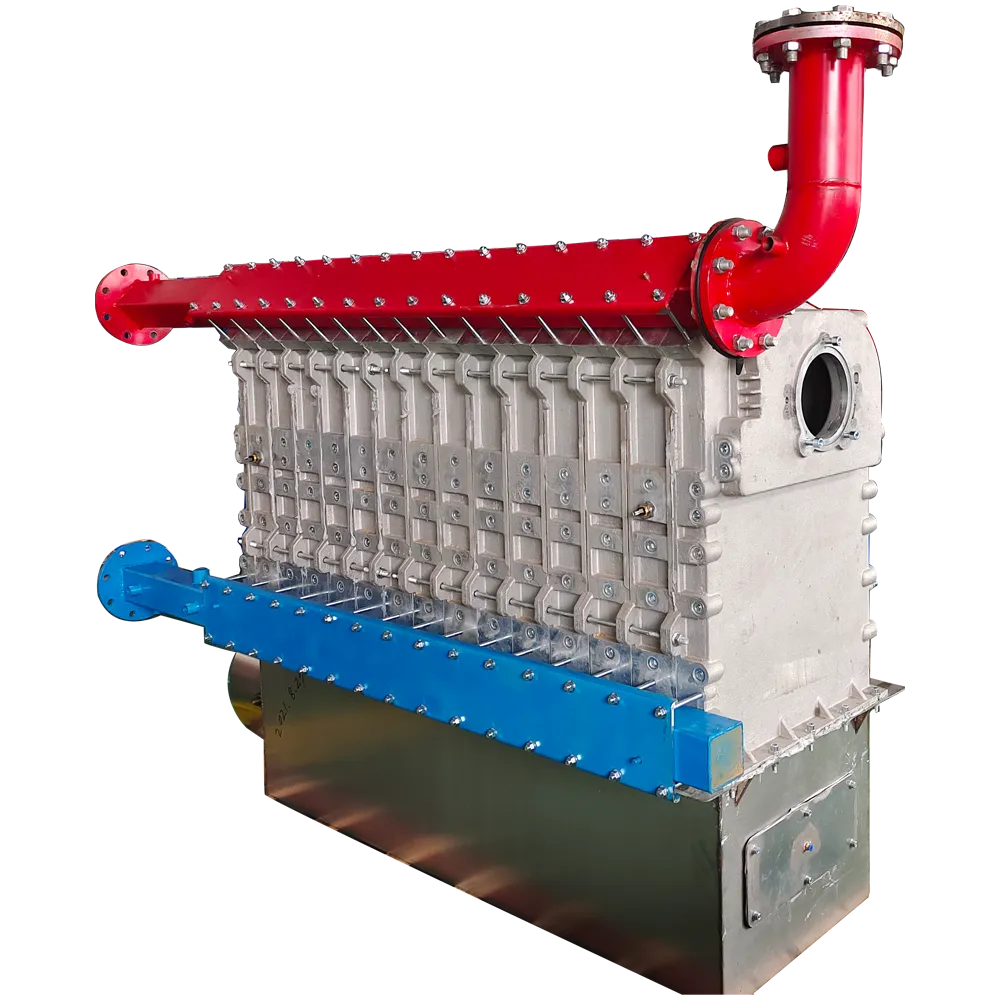

The Art and Science of Aluminum Mold Casting

Aluminum mold casting is a versatile and widely used manufacturing process that leverages the lightweight, strength, and corrosion-resistant properties of aluminum. This technique has gained popularity in various industries, including automotive, aerospace, electronics, and consumer goods, due to its efficiency and the superior quality of cast products. This article explores the fundamentals of aluminum mold casting, its advantages, applications, and future trends.

Understanding Aluminum Mold Casting

At its core, aluminum mold casting involves pouring molten aluminum into a mold cavity to create a specific shape. The process can be broken down into several key steps mold preparation, molten aluminum production, pouring, and cooling or solidification.

1. Mold Preparation Molds can be made from various materials, including sand, metal, and ceramic. Each type has its own advantages. Sand molds are less expensive and can accommodate complex shapes, while metal molds offer superior surface finish and durability.

2. Melting the Aluminum Aluminum has a relatively low melting point (around 660°C or 1220°F), making it easier to work with than many other metals. It is typically melted in furnaces, which can be powered by gas, electricity, or induction heating, depending on the scale and specifics of the operation.

3. Pouring Once the aluminum is fully melted, it is poured into the mold. Care must be taken to ensure that the molten aluminum flows smoothly and fills the mold completely to avoid defects such as air pockets or incomplete shapes.

4. Cooling and Solidification After pouring, the aluminum cools and solidifies, taking the shape of the mold. The cooling rate can influence the final properties of the cast, including its microstructure and mechanical strength.

Advantages of Aluminum Mold Casting

Aluminum mold casting offers several benefits, which contribute to its widespread adoption

aluminum mold casting

- Lightweight and Strong Aluminum is known for its high strength-to-weight ratio. Cast aluminum components are lighter than those made from iron or steel, making them ideal for applications where weight reduction is crucial.

- Corrosion Resistance Aluminum naturally forms a protective oxide layer, making it resistant to corrosion. This characteristic extends the lifespan of cast parts, especially in harsh environments.

- Design Flexibility The casting process permits intricate designs that may be difficult or impossible to achieve with other manufacturing methods. Thin walls and complex geometries are feasible, which adds to design innovation.

- Cost-Effective Production Once the mold is created, casting can be a highly economical process, especially for large production runs. The ability to produce multiple pieces simultaneously also enhances efficiency.

- Recyclability Aluminum is highly recyclable, and scrap aluminum can often be reused in new castings. This aspect not only supports sustainability but also reduces production costs.

Applications of Aluminum Mold Casting

Aluminum mold casting is employed in a wide array of applications. In the automotive industry, components such as engine blocks, transmission cases, and wheels are commonly produced using this method. Aerospace manufacturers utilize aluminum castings for parts like housings and structural components due to their lightweight nature and strength. Additionally, consumer products, from kitchen appliances to electronic housings, often feature aluminum cast components because of their aesthetic appeal and durability.

Future Trends

As industries evolve and focus on innovation, the field of aluminum mold casting is also transforming. Advances in technology, such as the incorporation of computer-aided design (CAD) and additive manufacturing techniques, are enhancing the capabilities of traditional casting methods. These innovations allow for better mold designs, improved precision, and reduced lead times. Furthermore, as the global emphasis on sustainability grows, strategies to minimize waste and enhance the recycling of aluminum will likely become more prevalent in casting operations.

In conclusion, aluminum mold casting stands as a testament to the harmonious blend of art and science in manufacturing. With its numerous benefits and wide-ranging applications, it is poised to remain a crucial method in producing high-quality, efficient, and environmentally friendly products for years to come. As technology continues to advance, the future of aluminum mold casting looks brighter than ever, promising even more innovative possibilities.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025