- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 18, 2024 11:40 Back to list

Buy Durable Dry Cast Concrete Pipe Mold Bottom Rings for Your Projects

Understanding the Importance of Buying Dry Cast Reinforced Concrete Pipe Mold Bottom Rings

In the world of construction and civil engineering, the materials used play a crucial role in the durability and reliability of infrastructures. Among these materials, concrete stands out as one of the most essential. Specifically, dry cast reinforced concrete is widely recognized for its strength, resilience, and versatility. When it comes to creating concrete pipes, particularly for drainage, sewerage systems, or other utilities, the manufacturer’s choice of molds is vital. One of the key components in this process is the bottom ring of the pipe mold. In this article, we delve into why buying high-quality dry cast reinforced concrete pipe mold bottom rings is essential for various construction projects.

What Are Dry Cast Reinforced Concrete Pipe Mold Bottom Rings?

Dry cast reinforced concrete pipe mold bottom rings are critical components used in the manufacturing of concrete pipes. These molds are designed to shape and support the dry cast concrete material as it cures, ensuring the final product achieves the necessary structural integrity. The bottom ring specifically provides a foundational component that helps maintain the shape and alignment of the pipe, making it a key element in producing quality concrete pipes.

Advantages of Dry Cast Concrete

One of the primary benefits of using dry cast concrete is its ability to yield high-quality, durable products. Dry cast concrete has a lower water-cement ratio, resulting in a denser and more robust final product. This is particularly advantageous for concrete pipes that must withstand environmental stresses, including soil pressure, water flow, and other external forces. Moreover, dry cast concrete can cure at a faster rate, allowing for quicker production times, which is beneficial for large-scale construction projects where time is of the essence.

Importance of High-Quality Mold Bottom Rings

Investing in high-quality dry cast reinforced concrete pipe mold bottom rings is paramount for several reasons

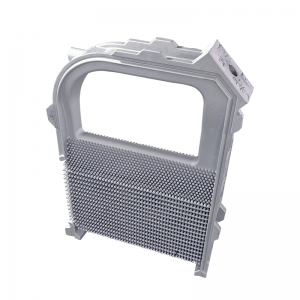

buy dry cast reinfored concrete pipe mold bottom ring

1. Precision and Consistency Mold bottom rings that are well-manufactured ensure that each pipe produced retains the intended shape and dimensions. This precision in the manufacturing process is crucial for compatibility during installation and for meeting industry standards.

2. Durability High-quality molds can withstand the rigorous demands of the casting process. Molds made from robust materials are less likely to warp or deteriorate over time, which ensures a longer lifespan and reduces the need for frequent replacements.

3. Cost-Effective Solutions By opting for durable and reliable bottom rings, manufacturers can save money in the long run. Fewer mold replacements mean reduced material costs and less downtime in production.

4. Improved Structural Integrity Molds that are designed with the correct specifications will help produce pipes that meet or exceed industry strength requirements. This is particularly important in applications where pipes are subjected to high loads or harsh environmental conditions.

5. Ease of Use Well-designed bottom rings facilitate easier assembly and disassembly in the manufacturing process, enhancing operational efficiency and productivity.

Conclusion

In conclusion, the choice to buy dry cast reinforced concrete pipe mold bottom rings is not merely a trivial decision but rather a critical investment in the overall quality and performance of concrete pipes. For contractors, manufacturers, and civil engineers, understanding the significance of these components is essential. By prioritizing quality in their production materials, stakeholders can ensure that their concrete pipes not only meet but exceed the expectations for safety, durability, and efficiency in various infrastructure applications. This commitment to quality ultimately leads to more reliable construction projects and contributes positively to the longevity of public works and utility systems.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025