- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 10, 2024 04:24 Back to list

Purchase Durable Ductile Iron Pipe Molds and Pallets for Efficient Production

The Importance of Ductile Iron Pipe Molds and Pallets in Modern Infrastructure

In recent years, the growing demand for durable and reliable piping systems has led to the increased popularity of ductile iron pipes. These pipes are known for their strength, resistance to corrosion, and flexibility under stress, making them ideal for various applications, from water supply to sewage systems. However, the production of these pipes relies heavily on high-quality molds and pallets, which play a crucial role in ensuring the efficiency and precision of the manufacturing process.

Understanding Ductile Iron

Ductile iron is a type of cast iron that contains small amounts of nodular graphite. This unique composition grants it superior mechanical properties compared to traditional cast iron, including higher tensile strength and ductility. As a result, ductile iron pipes can withstand higher pressures and harsher environmental conditions, making them an excellent choice for both municipal and industrial applications.

The Role of Molds in Pipe Production

Molds are essential in the manufacturing of ductile iron pipes as they shape the molten iron during the casting process. High-quality molds not only ensure dimensional accuracy but also improve surface finish and reduce production flaws. The design of these molds is crucial; they must allow for the proper flow of molten iron, minimize turbulence, and facilitate easy removal of the finished product.

When sourcing molds for ductile iron pipe production, it is important to consider factors such as material composition, heat resistance, and durability

. Advanced manufacturing technologies, like computer-aided design (CAD) and 3D printing, have revolutionized the mold-making process, allowing for more complex shapes and improved performance.The Importance of Pallets

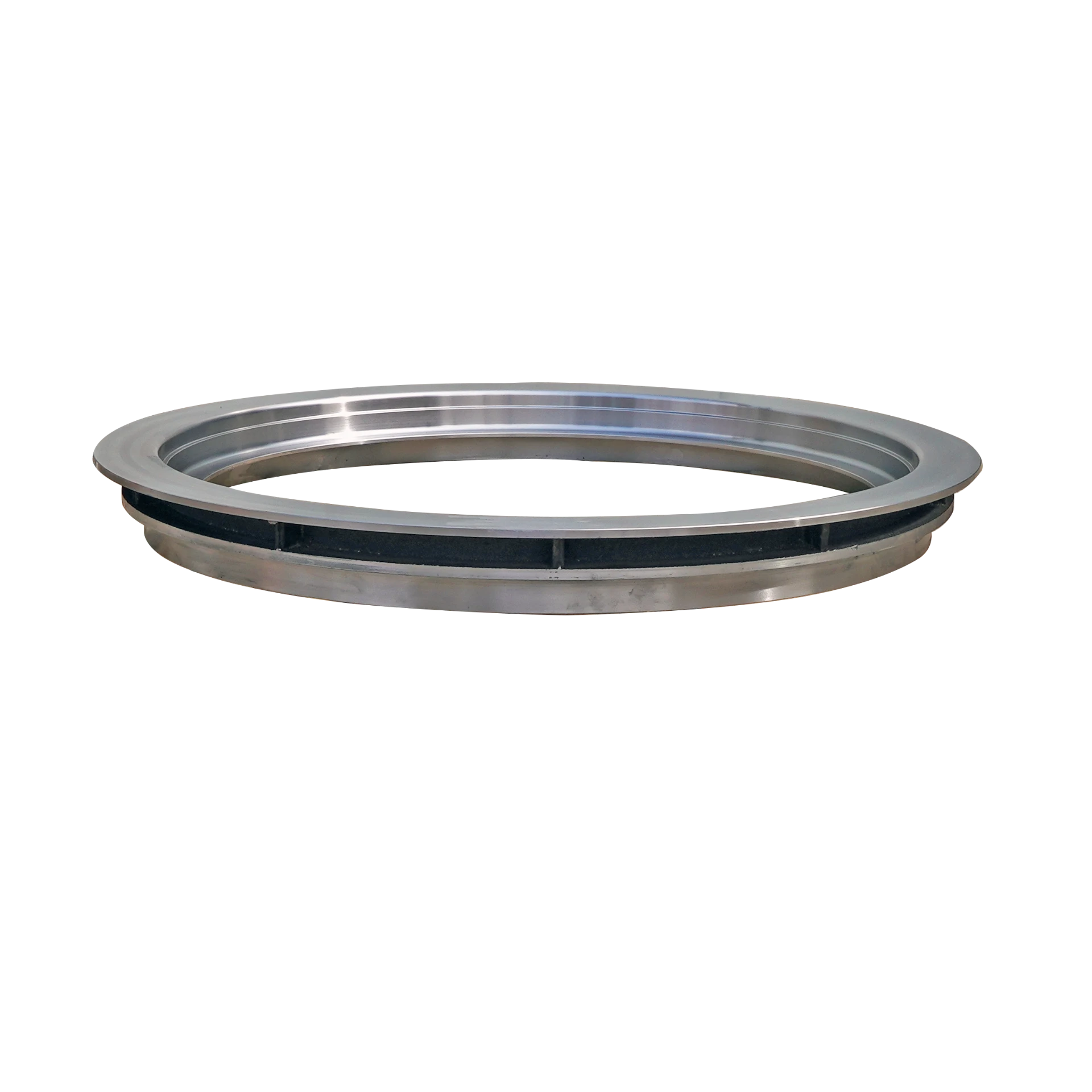

buy ductile iron pipe mold pallet

Pallets serve as the foundation for transporting and storing molds and the finished pipes. They need to be sturdy enough to support heavy weights and resistant to deterioration from environmental factors like moisture and temperature fluctuations. The right pallet can enhance workflow by enabling efficient handling and quick transportation, thereby reducing production downtime.

When purchasing pallets, manufacturers should consider factors such as load capacity, material type, and design features. Pallets made from durable materials like plastic or treated wood often outperform traditional materials in terms of longevity and resistance to wear and tear. Additionally, using pallets designed for easy stacking and transport can optimize warehouse space and streamline operations.

Best Practices for Sourcing Molds and Pallets

When looking to buy ductile iron pipe molds and pallets, manufacturers should prioritize working with reputable suppliers who understand the specific needs of the industry. It's essential to evaluate the supplier’s track record, customer service, and capability to provide customized solutions tailored to individual production requirements.

Quality assurance is another critical aspect. Molds and pallets should meet industry standards and undergo rigorous testing to ensure they can withstand the demanding conditions typical of ductile iron pipe production. Collaborating with suppliers who offer certifications can provide peace of mind regarding the quality and reliability of the products being purchased.

Conclusion

Ductile iron pipes are a cornerstone of modern infrastructure, and the processes that lead to their creation are equally significant. The role of high-quality molds and durable pallets cannot be overstated, as they directly impact production efficiency, product quality, and overall operational success. By investing in superior molds and pallets, manufacturers can ensure that they not only meet the demands of today’s infrastructure needs but also position themselves for future growth in a competitive market. Thus, understanding and selecting the right tools for ductile iron pipe manufacturing is essential in contributing to the longevity and effectiveness of water and sewage systems globally.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025