- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 07, 2024 11:32 Back to list

buy machinery parts

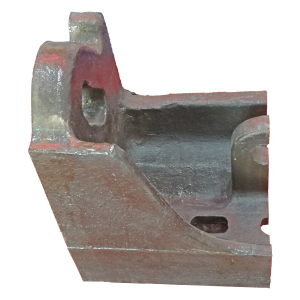

Understanding the Importance of Purchasing Machinery Parts

In today’s ever-evolving industrial landscape, the efficiency of machinery is paramount to maintaining production standards and minimizing downtime. The reliability and functionality of machinery largely depend on the quality of vital components that make up its structure. As businesses continue to seek ways to optimize their operation, the importance of buying machinery parts cannot be overstated.

Buying machinery parts involves more than just selecting the cheapest option available. It is essential to consider quality, compatibility, and supplier reputation. High-quality parts ensure that machinery operates smoothly, which in turn enhances productivity and prolongs equipment lifespan. When machinery parts are subpar, the risk of breakdown or failure increases, potentially leading to costly downtime and repairs.

Understanding the Importance of Purchasing Machinery Parts

Additionally, leveraging a reliable supplier is crucial in the purchasing process. Established suppliers often have a track record of quality and customer service. They can provide valuable insights into the best parts for your specific machinery and may offer warranties or service agreements, adding another layer of security to your investment. Building a relationship with a trusted supplier can also lead to better pricing, access to new products, and tailored support.

buy machinery parts

Another critical factor to take into account is the balance between cost and quality. While opting for cheaper parts may seem like an attractive proposition, it is often a false economy. Low-quality parts might save money initially, but they can lead to greater expenses down the line due to inefficiencies, frequent replacements, or mechanical issues. Therefore, businesses should evaluate their investments by weighing short-term savings against long-term benefits, emphasizing quality over price.

Furthermore, as industries move towards sustainability, it is becoming increasingly relevant to choose machinery parts from suppliers that prioritize eco-friendly practices. Sustainable manufacturing methods not only contribute positively to the environment but also enhance a company's corporate reputation. By making informed choices about machinery parts and supporting suppliers who practice sustainability, businesses can play a part in fostering a more sustainable industrial ecosystem.

Lastly, it’s vital to stay updated with advancements in technology. The machinery and equipment field is continuously evolving, and newer parts may offer enhanced performance and efficiency. Keeping abreast of the latest trends and innovations can lead businesses to discover parts that better serve their operational needs and contribute to overall productivity.

In conclusion, buying machinery parts is a crucial aspect of ensuring operational efficiency and longevity of equipment in any industry. By focusing on quality, compatibility, supplier reliability, and technological advancements, businesses can make informed purchasing decisions that benefit their operations in the long run. With the right machinery parts, companies can enhance productivity, reduce downtime, and ultimately, achieve their operational goals.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025