- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 16, 2024 22:09 Back to list

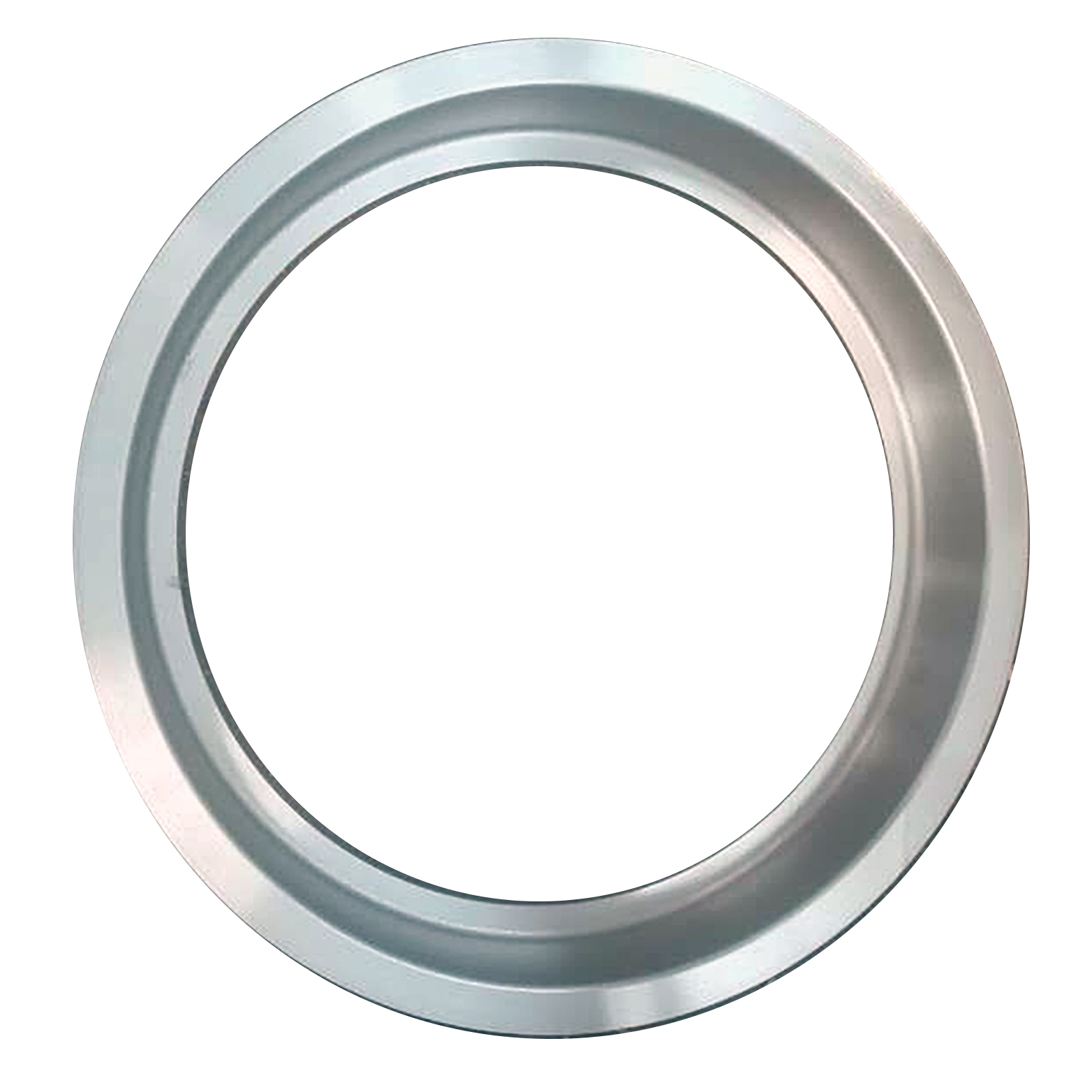

Exporting Carbon Steel Lost Wax Casting Solutions for Global Industries

The Significance of Carbon Steel Lost Wax Casting Exporters

Carbon steel lost wax casting is a specialized process that plays a crucial role in manufacturing a wide range of metal products across various industries. This technique, which is also known as investment casting, allows for the creation of complex shapes with high precision, making it a preferred choice among manufacturers. As the global demand for such products continues to rise, the role of carbon steel lost wax casting exporters has become increasingly significant.

One of the primary advantages of using carbon steel in lost wax casting is its inherent strength and durability. Carbon steel alloys are known for their robust properties, which include excellent wear resistance and high tensile strength. This makes them ideal for producing critical components in industries such as automotive, aerospace, and heavy machinery. Exporters specializing in carbon steel lost wax casting are well aware of these benefits and leverage them to cater to a variety of market needs.

Moreover, the lost wax casting process is highly versatile. It allows for intricate designs and fine details that are difficult to achieve with traditional casting methods. This flexibility is pivotal for industries requiring customized solutions. Exporters capitalize on this versatility by offering tailored products that meet specific client requirements. They can work closely with clients to develop prototypes and make adjustments throughout the production process, ensuring the final product aligns perfectly with the intended design specifications.

carbon steel lost wax casting exporters

In addition to the technical advantages, the global market for carbon steel lost wax casting is supported by rising economic activities in developing nations. Countries in Asia, Europe, and the Americas are witnessing increased demand for high-quality metal components, creating a fertile ground for exporters. As international trade and globalization continue to expand, carbon steel lost wax casting exporters are positioned to take advantage of new opportunities in various markets.

Furthermore, many exporters are committed to sustainable practices. As environmental concerns become more pronounced, the importance of eco-friendly manufacturing processes cannot be overstated. Leading exporters are increasingly adopting green technologies and practices to minimize waste and energy consumption during production. This not only enhances their reputation but also meets the changing expectations of consumers who prefer environmentally responsible products.

To succeed in the competitive landscape, carbon steel lost wax casting exporters must stay ahead of industry trends and technological advancements. Investing in research and development is crucial for innovation and maintaining product quality. By adopting advanced techniques and machinery, exporters can streamline their processes, reduce lead times, and improve overall efficiency, which ultimately benefits their clients.

In conclusion, carbon steel lost wax casting exporters play a vital role in the global manufacturing landscape. Their ability to offer high-quality, custom products and adapt to market demands positions them as essential players in the supply chain. With a focus on innovation and sustainability, they are set to thrive in an increasingly competitive environment, catering to diverse industries while contributing to economic growth worldwide. As the industry evolves, the importance of these exporters will only continue to grow.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025