- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 22, 2024 09:28 Back to list

carbon steel lost wax casting factory

The Benefits of Carbon Steel Lost Wax Casting

Lost wax casting, also known as investment casting, is a sophisticated method that has been used for centuries to produce intricate metal parts. Among various materials, carbon steel is a prominent choice used in this technique due to its excellent mechanical properties and versatility. This article explores the advantages of using carbon steel in lost wax casting and how specialized factories can make a significant difference in the quality of the final product.

One of the primary benefits of carbon steel is its strength and durability. Carbon steel contains a mix of iron and carbon, which enhances its hardness and tensile strength compared to other metals. This makes it ideal for producing components that must withstand high stress and wear, such as machinery parts, automotive components, and structural elements. In a lost wax casting factory, the precision of the process allows for the creation of complex shapes that would be challenging to achieve with traditional manufacturing methods.

Moreover, the lost wax casting process is renowned for its high level of accuracy. The technique involves creating a wax pattern that is coated in a ceramic shell. Once the shell is hardened, the wax is melted away, leaving a cavity that is then filled with molten carbon steel. This method allows for the production of parts with tight tolerances, excellent surface finish, and intricate designs. This level of precision is essential for industries where even minor deviations can lead to significant functional issues.

carbon steel lost wax casting factory

In addition to strength and precision, carbon steel lost wax casting is also cost-effective. While the initial setup might require investment in patterns and molds, the ability to produce high volumes of consistent, high-quality components reduces overall production costs. This is particularly beneficial for manufacturers looking to scale up their operations without compromising on quality.

Sustainability is another aspect where using a lost wax casting factory can be advantageous

. Many factories are adopting environmentally friendly practices, such as recycling scrap material and utilizing energy-efficient processes. This aligns with global efforts towards sustainability and minimizing waste in manufacturing.Furthermore, the versatility of carbon steel allows it to be tailored for specific applications by adjusting its carbon content and adding other alloying elements. This means that a lost wax casting factory can produce a wide range of components suitable for various industries, from aerospace to construction.

In conclusion, carbon steel lost wax casting offers numerous benefits, including strength, precision, cost-effectiveness, and versatility. Specialized factories that employ this technique can produce high-quality components that meet the demanding standards of modern engineering. As industries continue to evolve, the role of such casting methods will likely remain pivotal in achieving innovative design and functionality.

-

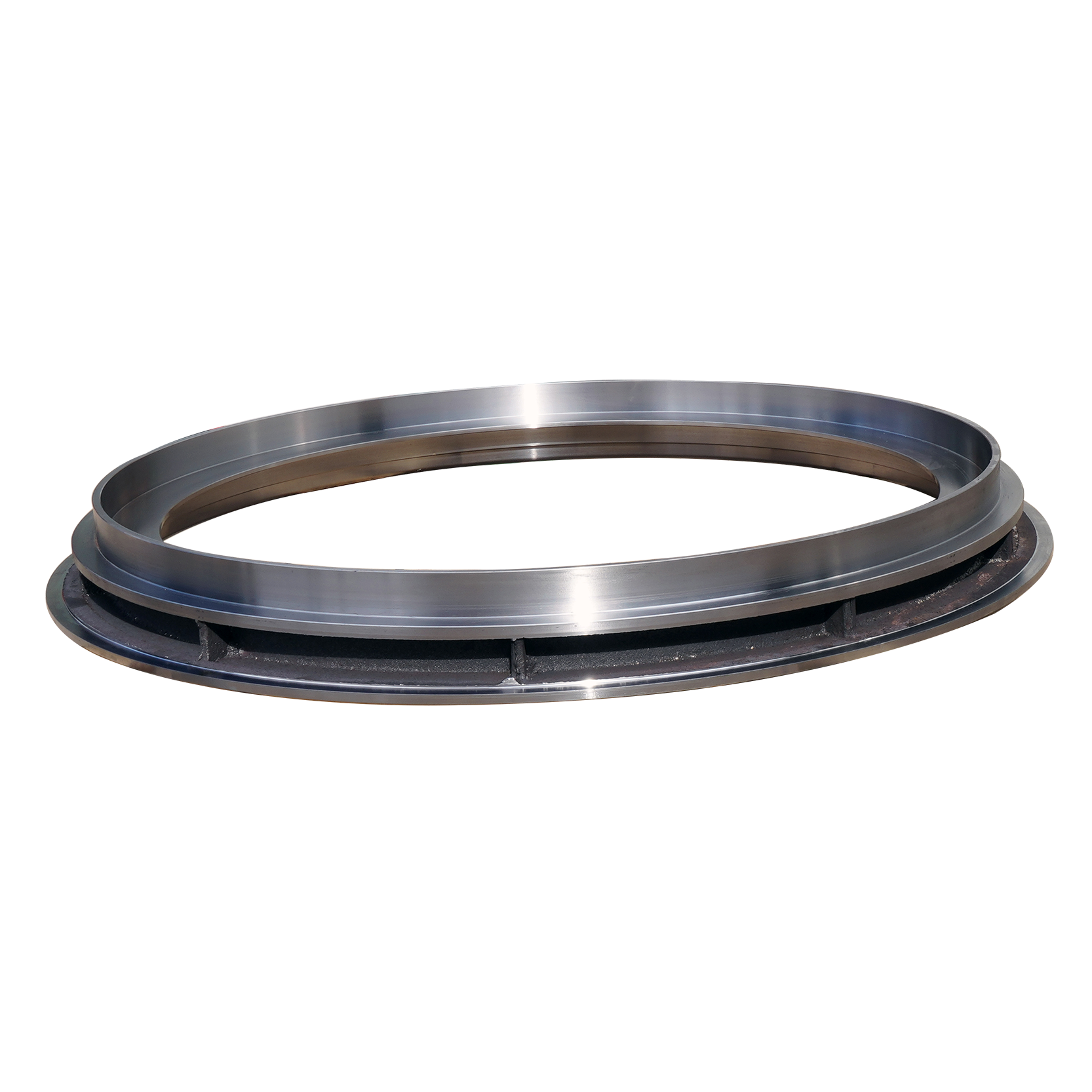

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025