- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 20, 2024 09:21 Back to list

cast aluminum silicon radiator casting exporter

The Rise of Cast Aluminum Silicon Radiator Casting Exporters

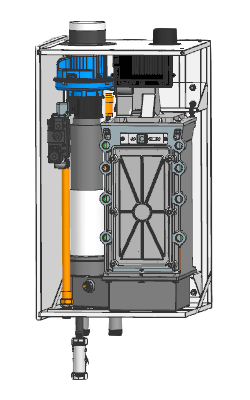

In recent years, the global automotive and manufacturing industries have consistently sought innovative solutions to enhance performance, sustainability, and efficiency. One crucial component that has emerged prominently in this search is the cast aluminum silicon radiator. Recognized for its lightweight, excellent thermal conductivity, and corrosion resistance, this alloy has become a vital player in the heating and cooling systems of various machines, particularly in vehicles.

The process of cast aluminum silicon radiator casting involves using aluminum silicon alloys, which are renowned for their casting properties. These alloys provide excellent fluidity in molten form, allowing for intricate designs and lightweight structures that traditional materials cannot offer. This quality is especially important in the automotive industry, as manufacturers strive to reduce vehicle weight, enhance fuel efficiency, and improve overall performance.

With the increasing demand for high-quality cast aluminum silicon radiators, exporters around the world have begun to capitalize on this trend. Countries such as China, India, and various nations in Europe have emerged as key players in the export market for these components, significantly contributing to their respective economies.

Market Dynamics and Demand

The demand for aluminum silicon radiator castings is primarily driven by the automotive sector, where there is an unrelenting push towards lighter, more efficient vehicles. As governments implement stricter emissions regulations and consumers become more environmentally conscious, manufacturers are compelled to adopt innovative materials and production methods. Cast aluminum silicon finds itself at the forefront of this transformation, and as such, the market for its export is booming.

Furthermore, the heating, ventilation, and air conditioning (HVAC) sector has also recognized the advantages of using aluminum silicon radiators. These components provide effective heat transfer, are lightweight, and can be easily recycled. As environmental sustainability becomes a critical factor in manufacturing processes, the pivot towards using recyclable materials like aluminum strengthens the case for increased exports of aluminum silicon radiator castings.

Quality and Standards

For exporters in the aluminum silicon radiator casting market, maintaining high-quality standards is paramount. The production process must adhere to stringent industry benchmarks to ensure that the final products meet the performance requirements mandated by clients. Various certifications, such as ISO9001 for quality management and ISO14001 for environmental management, are essential for exporters to secure their position in the global market.

cast aluminum silicon radiator casting exporter

To ensure quality, many exporting companies invest in advanced manufacturing technologies and automated processes. These investments yield precision-cast components that fulfill the rigorous specifications of clients, thereby enhancing their global competitiveness. Additionally, a focus on research and development allows exporters to innovate and introduce superior products that cater to evolving market demands.

Export Strategies and Trends

Successful exporters of cast aluminum silicon radiator castings employ multiple strategies to thrive in a competitive market. Building strong relationships with international clients is essential, as trust and reliability play critical roles in cross-border transactions. Many exporters participate in global trade shows, allowing them to showcase their products and forge new partnerships.

Digital transformation also contributes significantly to the success of these exporters. Many have embraced e-commerce platforms and digital marketing to reach a broader audience. Creating a robust online presence enables them to connect with potential clients in multiple countries, increasing visibility and sales potential.

Moreover, as logistics and supply chain processes evolve, exporters are now better equipped to navigate challenges related to shipping and product distribution. This capability is vital for maintaining timely delivery, ensuring client satisfaction, and optimizing operational efficiency.

Conclusion

The export market for cast aluminum silicon radiator casting is poised for significant growth as industries increasingly adopt lightweight and high-performance materials. Thanks to its excellent properties, the demand for these radiators will likely continue to rise, reflecting broader trends towards sustainability and efficiency.

As global markets grow more interconnected, exporters who prioritize quality, innovation, and strategic partnerships will not only adapt to changing conditions but will also play a vital role in shaping the future of manufacturing and automotive performance. The journey of cast aluminum silicon radiators from production lines to international markets is a testament to the evolving landscape of global trade and technological advancement.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025