- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 05, 2024 04:57 Back to list

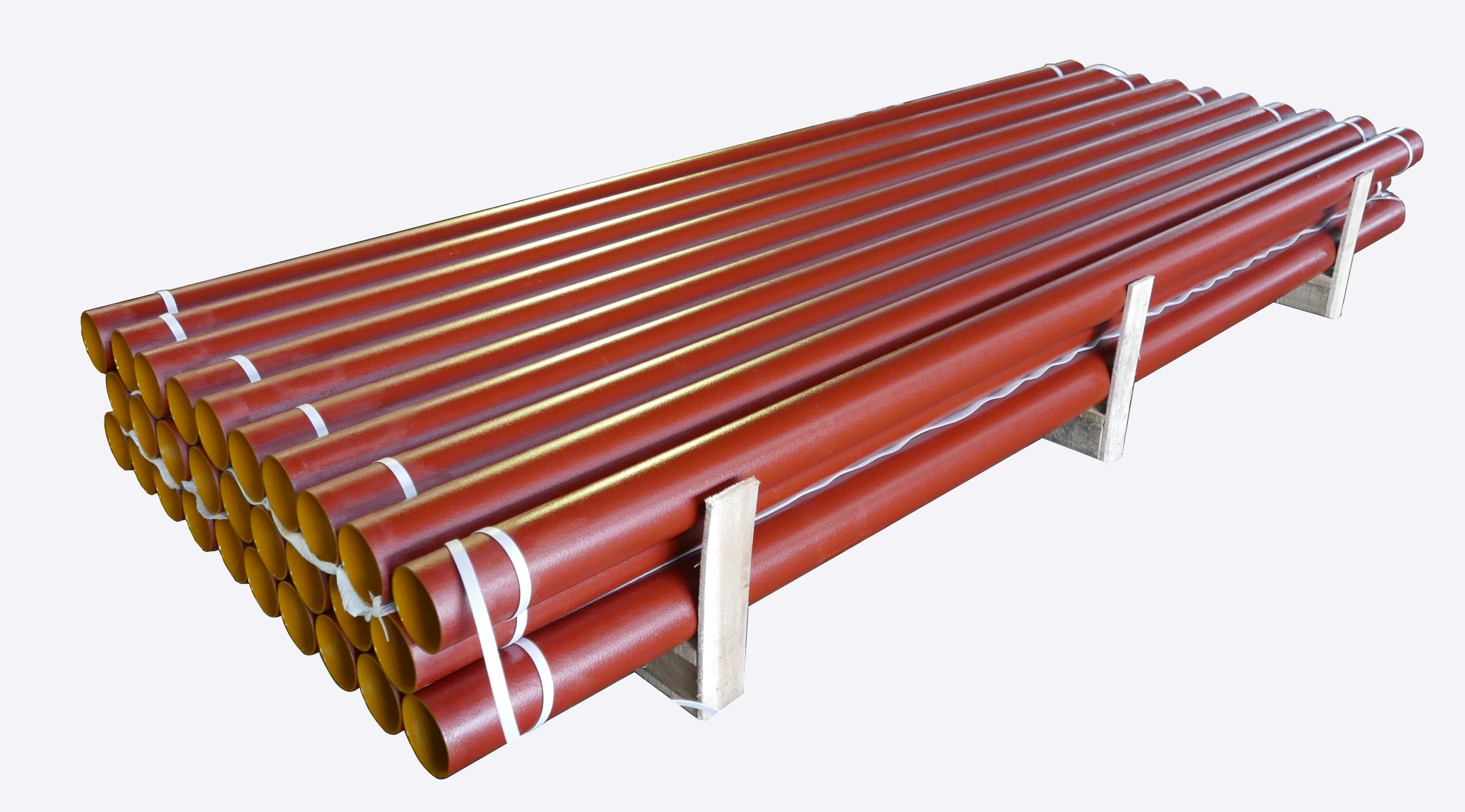

cast foundry supplier

The Importance of Cast Foundry Suppliers in Modern Manufacturing

In today’s industrial landscape, the role of cast foundry suppliers has become increasingly vital. These suppliers provide the necessary raw materials and expertise to manufacture a wide range of components used in various sectors, including automotive, aerospace, construction, and machinery. The intricate processes involved in casting not only require high-quality materials but also sophisticated technology, skilled labor, and strict quality controls. Therefore, understanding the significance of cast foundry suppliers is essential for manufacturers aiming to enhance their productivity and efficiency.

Quality Assurance and Material Sourcing

One of the primary functions of a cast foundry supplier is to ensure that the materials used in manufacturing processes meet industry standards. This includes sourcing high-quality metals, such as aluminum, iron, and other alloys, which are crucial in producing durable and reliable castings. Suppliers play a critical role in the verification of these materials, conducting rigorous testing and inspections to guarantee compliance with both domestic and international standards.

This focus on quality assurance is paramount, as even minor defects in the materials can lead to significant failures in the final products. By providing reliable materials and thorough quality checks, cast foundry suppliers help manufacturers avoid costly recalls and reputation damage, thus providing a competitive edge in the market.

Technological Advancements and Innovation

The foundry industry has witnessed significant technological advancements in recent years, with suppliers investing in modern casting methods such as 3D printing, vacuum casting, and investment casting. These innovative processes not only enhance the precision and quality of cast products but also reduce waste and energy consumption. Suppliers who stay at the forefront of these technological developments give their clients access to the latest advancements, enabling them to improve their own production processes.

cast foundry supplier

Moreover, many cast foundry suppliers now offer specialized services such as design assistance and material selection guidance. By collaborating with manufacturers in the early stages of product development, suppliers can help optimize designs for manufacturability, thereby improving efficiency and reducing costs.

Reliability and Supply Chain Management

In an era where just-in-time manufacturing is becoming the norm, reliability in the supply chain is crucial. Cast foundry suppliers must be capable of delivering materials and components consistently and on time. Any delay in supply can halt production lines and lead to significant financial losses. To mitigate this risk, many suppliers implement robust supply chain management practices that include maintaining sufficient inventory levels, establishing strong relationships with logistics partners, and utilizing advanced forecasting techniques.

Additionally, the global nature of the foundry industry means that suppliers are often required to navigate complex international trade regulations. A dependable cast foundry supplier will not only understand these regulations but also have the necessary infrastructure in place to handle imports and exports efficiently.

Partnering for Success

Establishing a partnership with a reputable cast foundry supplier can be a game-changer for manufacturers. By aligning with a supplier that understands their specific needs, manufacturers can streamline their operations and improve outcomes. This relationship can foster collaboration, enabling both parties to share knowledge and implement best practices, ultimately leading to enhanced product quality and innovation.

In conclusion, cast foundry suppliers are more than just providers of materials; they are integral partners in the manufacturing process. Their commitment to quality assurance, technological innovation, reliable supply chains, and collaborative partnerships defines the competitive landscape of modern manufacturing. As industries continue to evolve, the role of these suppliers will undoubtedly become even more crucial, shaping the future of production and component manufacturing.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025