- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 07, 2024 14:17 Back to list

Casting Factory Innovations for Efficient Metal Production and Design Solutions

The Future of Casting Factories Innovations and Challenges

As industries evolve, the role of casting factories becomes increasingly pivotal in shaping the future of manufacturing. These facilities, dedicated to the production of metal components through the casting process, are integral to various sectors including automotive, aerospace, and construction. With the rise of advanced technologies and sustainability initiatives, the casting factory is undergoing transformative changes that promise to enhance productivity, efficiency, and environmental stewardship.

Casting is one of the oldest manufacturing processes, dating back thousands of years. It involves pouring molten metal into molds to create shapes that meet specific design requirements. Traditionally, this method was associated with a high level of labor intensity and time consumption. However, the advent of automation and digital technologies is revolutionizing this age-old practice.

The Future of Casting Factories Innovations and Challenges

Moreover, the application of 3D printing technology in the design and production of molds is paving the way for more customized solutions. With 3D printing, complex geometries can be easily achieved, which was previously difficult or impossible with traditional mold-making methods. This capability not only enhances design flexibility but also reduces material waste, further contributing to sustainability efforts within the industry.

casting factory

Additionally, casting factories are increasingly adopting lean manufacturing principles. This approach focuses on minimizing waste and maximizing productivity, profoundly altering how factories operate. By analyzing workflows and optimizing processes, factories can achieve higher efficiency while reducing costs. This shift is critical in a competitive market where margins are often tight, and the demand for high-quality products is ever-increasing.

However, the transition toward modernization comes with its share of challenges. One significant hurdle is the need for skilled labor. As casting processes become more technologically advanced, the demand for skilled technicians and operators who can manage and maintain these sophisticated systems increases. Investing in employee training and development is essential to bridge this skills gap and ensure that the workforce is prepared to meet the demands of modern casting operations.

Environmental considerations are also at the forefront of challenges faced by casting factories. The production process often involves significant energy consumption and emissions. As global awareness of climate change rises, there is increasing pressure for manufacturers to adopt greener practices. This has led to the exploration of alternative materials and processes, such as using recycled metals and implementing energy-efficient technologies. Factories are also investing in carbon capture and storage solutions to mitigate their environmental impact.

In conclusion, the future of casting factories is bright but fraught with challenges that need to be addressed. Technological advancements such as CNC machining and 3D printing, alongside lean manufacturing practices, are set to revolutionize the industry. However, the need for skilled labor and the push for sustainability remain critical areas for development. As casting factories adapt to these changes, they will play a crucial role in supporting the growth of various industries and ensuring a sustainable future for manufacturing. Embracing innovation while addressing challenges will define the success of casting factories in the years to come.

-

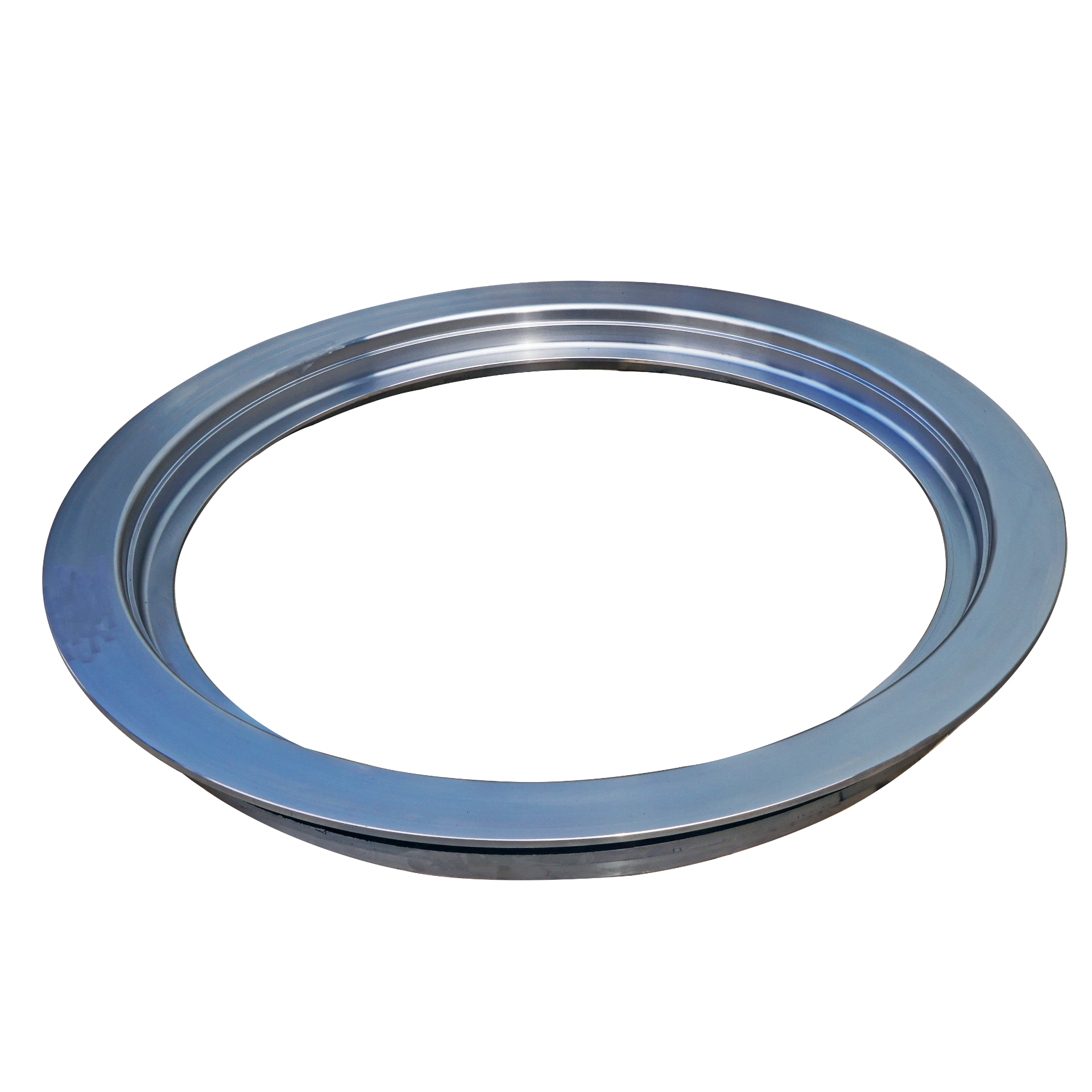

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025