- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 28, 2024 19:52 Back to list

Choosing the Right Supplier for Casting Parts in Your Manufacturing Process

Casting Parts Supplier The Critical Role in Manufacturing Processes

In the realm of manufacturing, the importance of casting parts cannot be overstated. These components serve as the backbone of countless products across various industries, from automotive to aerospace, and from consumer electronics to heavy machinery. The process of casting involves pouring molten material into a mold to create desired shapes and sizes, which are essential for the functionality and integrity of end products. In this context, the role of a casting parts supplier becomes critical. Let’s delve into what makes an effective casting parts supplier and the factors to consider when choosing one.

The Functions of a Casting Parts Supplier

A casting parts supplier plays multiple roles in the manufacturing ecosystem. Firstly, they provide the raw materials and finished components needed for production. This can include everything from iron, aluminum, and steel to advanced alloys that require specialized processes. Secondly, they can offer expertise in design and engineering, ensuring that the casting parts meet specific customer requirements and industry standards.

Many suppliers will also handle the logistics of transporting these parts, managing relationships with foundries, and ensuring that quality control processes are upheld. This assurance is vital as defects in casting can lead to costly delays and compromised product quality. Therefore, a reliable casting parts supplier should have stringent quality assurance protocols in place.

Quality Assurance and Standards

Quality is the cornerstone of any supplier relationship, especially in casting. A reputable casting parts supplier should comply with international standards such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). Regular audits and certifications are essential to maintain these standards. Suppliers might also employ Non-Destructive Testing (NDT) methods to ensure the integrity of the casting parts, further solidifying their reputation for reliability.

Customization and Technological Adaptability

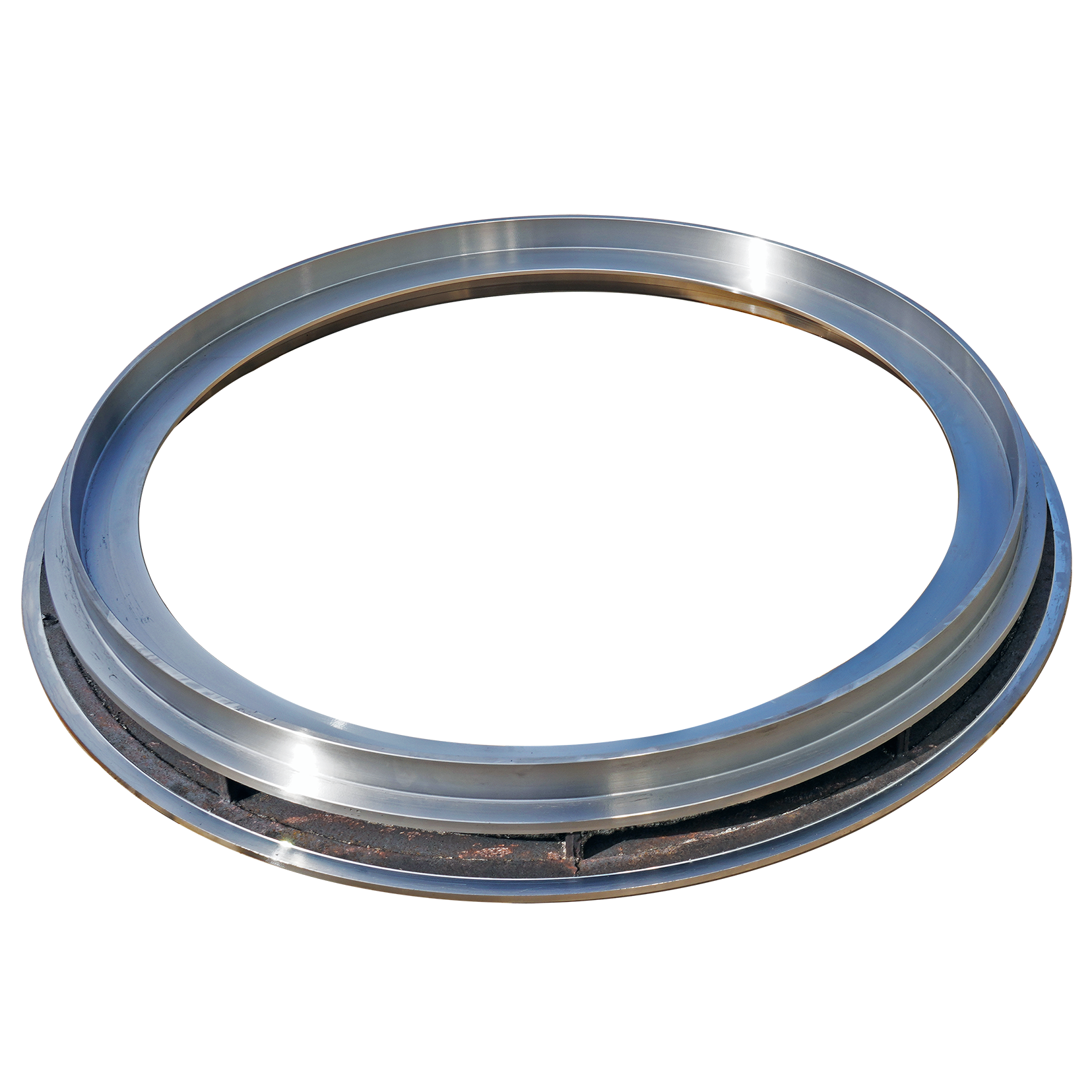

casting parts supplier

In today’s fast-paced manufacturing environment, customization is key. Each project might have unique requirements concerning dimensions, materials, and finishes. A capable casting parts supplier should offer tailored solutions, employing modern technologies such as 3D printing and computer-aided design (CAD) to facilitate rapid prototyping and faster turnaround times. This flexibility enables manufacturers to innovate without being constrained by the limitations of traditional casting methods.

Moreover, suppliers that invest in advanced manufacturing technologies often yield better precision and quality. For instance, the use of automated processes can enhance consistency, while sophisticated simulation software can predict casting defects before the physical manufacturing process even starts.

Sustainability Considerations

Sustainability is an increasingly important factor in manufacturing decisions. A responsible casting parts supplier will prioritize environmentally friendly practices, such as recycling scrap metal, minimizing waste, and reducing energy consumption. Suppliers that align their operations with sustainability goals not only contribute to environmental health but can also offer their clients a competitive edge in the marketplace, particularly as consumer demand for sustainable products rises.

Building a Long-Term Partnership

When selecting a casting parts supplier, businesses should consider not only the cost but also the potential for a long-term partnership. Establishing a collaborative relationship allows for better communication, improved understanding of product requirements, and ultimately, enhanced efficiency. A supplier that acts more like a partner can provide insights into industry trends, assist in problem-solving, and support future scaling of production needs.

Conclusion

Choosing the right casting parts supplier is a critical decision that can have far-reaching effects on manufacturing processes and product quality. By focusing on quality assurance, customization, technological adaptability, and sustainability, businesses can build successful partnerships that enhance productivity and ensure that they remain competitive in an ever-evolving market landscape. As casting continues to be a fundamental part of manufacturing, the suppliers that best understand and meet these demands will position themselves as valuable assets to their clients.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025