- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 04, 2024 19:08 Back to list

cast iron pipe mold bottom ring factory

The Importance of Cast Iron Pipe Mold Bottom Rings in Manufacturing

In the realm of industrial manufacturing, precision and durability are of utmost importance, particularly when it comes to components that play a direct role in shaping the final products. One such crucial component is the cast iron pipe mold bottom ring. This article explores the significance of these rings in the manufacturing process, their advantages, and the role of specialized factories in producing high-quality cast iron pipe mold bottom rings.

Understanding Cast Iron Pipe Mold Bottom Rings

Cast iron pipe mold bottom rings are essential parts used in the casting process, particularly in the production of pipes. These rings serve as the foundational component of the molds that shape the pipes during manufacturing. The material used, cast iron, is renowned for its excellent casting properties, high wear resistance, and ability to endure significant thermal stress. These attributes make it a preferred choice in various manufacturing applications, particularly in industries that demand longevity and reliability.

The Manufacturing Process

The manufacturing process of cast iron pipe mold bottom rings starts with the selection of high-quality raw materials. Factories specializing in the production of these components often source their iron from reputable suppliers to ensure that the final product meets rigorous industry standards. The process begins with melting the iron in a furnace, which is then poured into molds designed to create the specific shape of the bottom ring.

Once the metal has cooled and solidified, the molds are removed, and the rings undergo a series of finishing processes. These may include machining, grinding, and surface treatment to enhance their durability and performance. Quality control is a critical part of this process, as manufacturers must ensure that each bottom ring conforms to specific dimensions and tolerances, which are essential for seamless integration into the final mold assembly.

Advantages of Cast Iron Pipe Mold Bottom Rings

The use of cast iron pipe mold bottom rings in manufacturing offers several advantages

1. Durability Cast iron is known for its strength and durability, making it suitable for high-pressure applications. The rings can withstand harsh industrial conditions, contributing to the longevity of the molds.

cast iron pipe mold bottom ring factory

2. Thermal Stability Cast iron has excellent thermal conductivity and can withstand extreme temperatures without deforming. This property is crucial in processes that involve molten metal, where consistent thermal stability is required.

3. Cost-Effectiveness While the initial investment in cast iron may be higher compared to other materials, its durability reduces the need for frequent replacements and repairs, ultimately proving to be cost-effective in the long run.

4. Ease of Machining Cast iron is relatively easy to machine, allowing for customized modifications to meet specific manufacturing requirements or to enhance performance features.

The Role of Specialized Factories

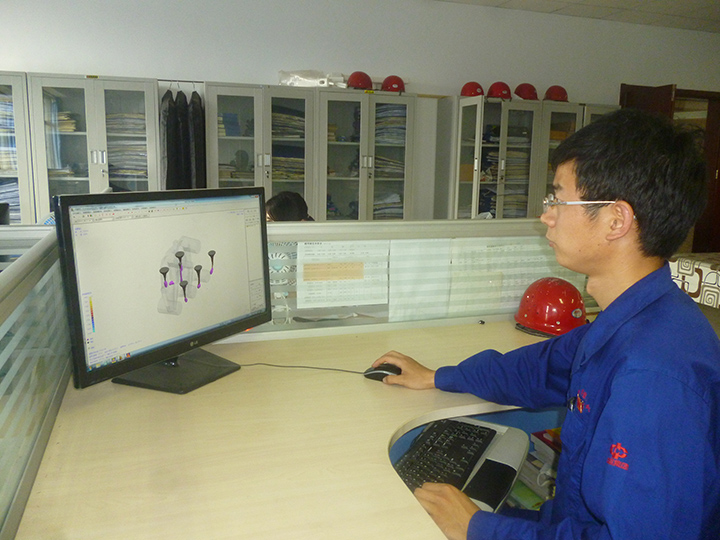

Factories that specialize in the production of cast iron pipe mold bottom rings play a vital role in ensuring the quality and consistency of these components. Such facilities are often equipped with advanced machinery and technology that enable them to produce intricate designs and maintain precise tolerances.

Moreover, the expertise of the workforce is paramount. Skilled technicians and engineers understand the nuances of the casting process and can implement innovative techniques to improve the efficiency and quality of the rings produced. These factories also emphasize environmental responsibility, utilizing sustainable practices in sourcing materials and minimizing waste.

Conclusion

In conclusion, cast iron pipe mold bottom rings are indispensable in the manufacturing of pipes. Their durability, thermal stability, and cost-effectiveness make them a preferred choice in industries that demand high performance. The specialized factories dedicated to their production ensure that these components are manufactured to the highest standards, thus contributing significantly to the overall quality of the end product.

As industries continue to evolve, the demand for reliable and efficient components like cast iron pipe mold bottom rings will remain strong. Investing in quality manufacturing practices and sustainable methods will ensure that these critical components are available to support the needs of modern manufacturing, paving the way for continued innovation and growth in the sector.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025