- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 04, 2024 17:08 Back to list

cast iron pipe schedule

Understanding Cast Iron Pipe Schedules

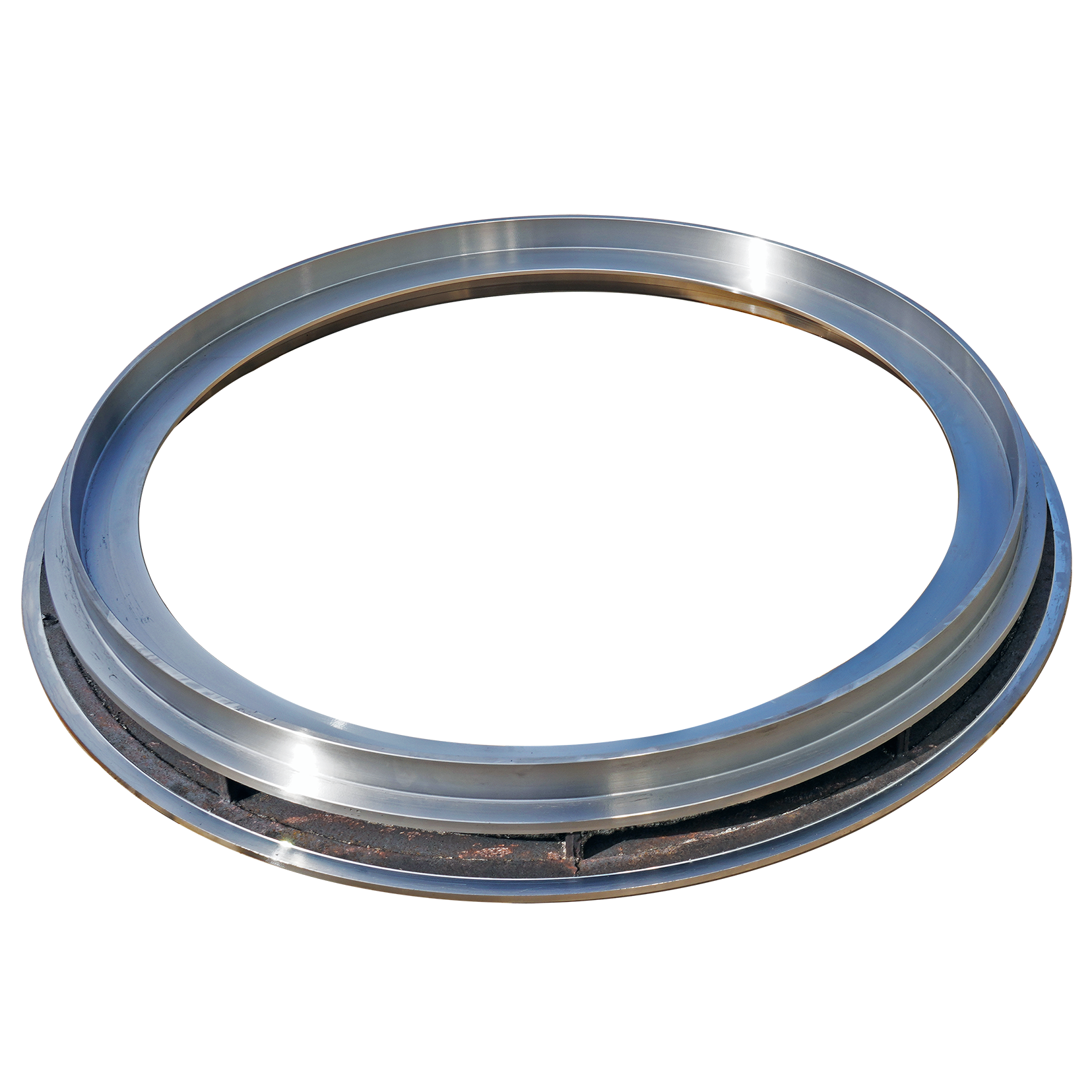

Cast iron pipes have been a staple in plumbing and construction for centuries. Known for their durability and strength, they are commonly used in sewer systems, drainage applications, and water distribution systems. One crucial aspect of cast iron piping is the concept of pipe schedule. This article will explore what pipe schedules are, their importance, particularly concerning cast iron pipes, and how they impact various applications.

What is Pipe Schedule?

Pipe schedule refers to the wall thickness of a pipe that is defined by standards set by organizations like the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM). The wall thickness not only determines the pipe's strength and durability but also impacts its ability to handle pressure and its overall flow capacity. For cast iron pipes, the schedule is typically indicated in a range that specifies the thickness suitable for various applications.

Why Use Cast Iron Pipes?

Cast iron pipes have numerous advantages that make them a preferred choice in many construction and plumbing scenarios. They are resistant to corrosion, have excellent noise-damping characteristics, and can withstand high temperatures and pressures. Additionally, cast iron is resistant to degradation due to its inherent properties, which can lead to a longer lifespan with minimal maintenance when installed correctly.

Different Pipe Schedules Explained

Pipe schedules are categorized by numbers, with common schedules including Schedule 40, Schedule 80, and others

.1. Schedule 40 This is the standard wall thickness for cast iron pipes used in most residential and light commercial applications. It provides a good balance of strength and weight, making it popular for drainage and venting systems.

cast iron pipe schedule

2. Schedule 80 This schedule has a thicker wall than Schedule 40, which allows it to handle higher pressures. It is typically used in more demanding applications, such as industrial settings or in scenarios where external stresses, such as deep burial or heavy loads, are expected.

3. Higher Schedules While Schedule 40 and Schedule 80 are the most commonly referenced, there are higher schedules (e.g., Schedule 100, Schedule 120) that are used in specialized applications requiring extra durability and resistance to pressure.

Impact of Pipe Schedule on Performance

The chosen pipe schedule significantly affects a system's performance. For instance, using a pipe with insufficient thickness may lead to failures under pressure, whereas opting for overly thick pipes may unnecessarily increase costs and installation complexity. Furthermore, flow rates can be affected as well; a thicker pipe may limit flow if the internal diameter is reduced compared to a thinner pipe of the same nominal diameter.

Installation Considerations

When selecting the appropriate cast iron pipe schedule, several factors should be taken into account, including the type of application, pressure requirements, environmental conditions, and local building codes. Additionally, proper installation practices are essential to ensure the longevity and reliability of the piping system. This includes correct jointing techniques, ensuring adequate support, and considering thermal expansion and contraction.

Conclusion

Cast iron pipes offer substantial benefits due to their strength, durability, and resistance to corrosion, making them an ideal choice for various plumbing needs. Understanding pipe schedules is vital for selecting the correct pipe for any given application. By assessing factors such as pressure requirements, environmental challenges, and specific application needs, construction professionals can make informed decisions, ensuring a safe and reliable plumbing system. As technology progresses and building practices evolve, the versatility and resilience of cast iron pipes remain significant in modern construction, providing longevity and performance to infrastructure projects.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025