- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 07, 2024 17:12 Back to list

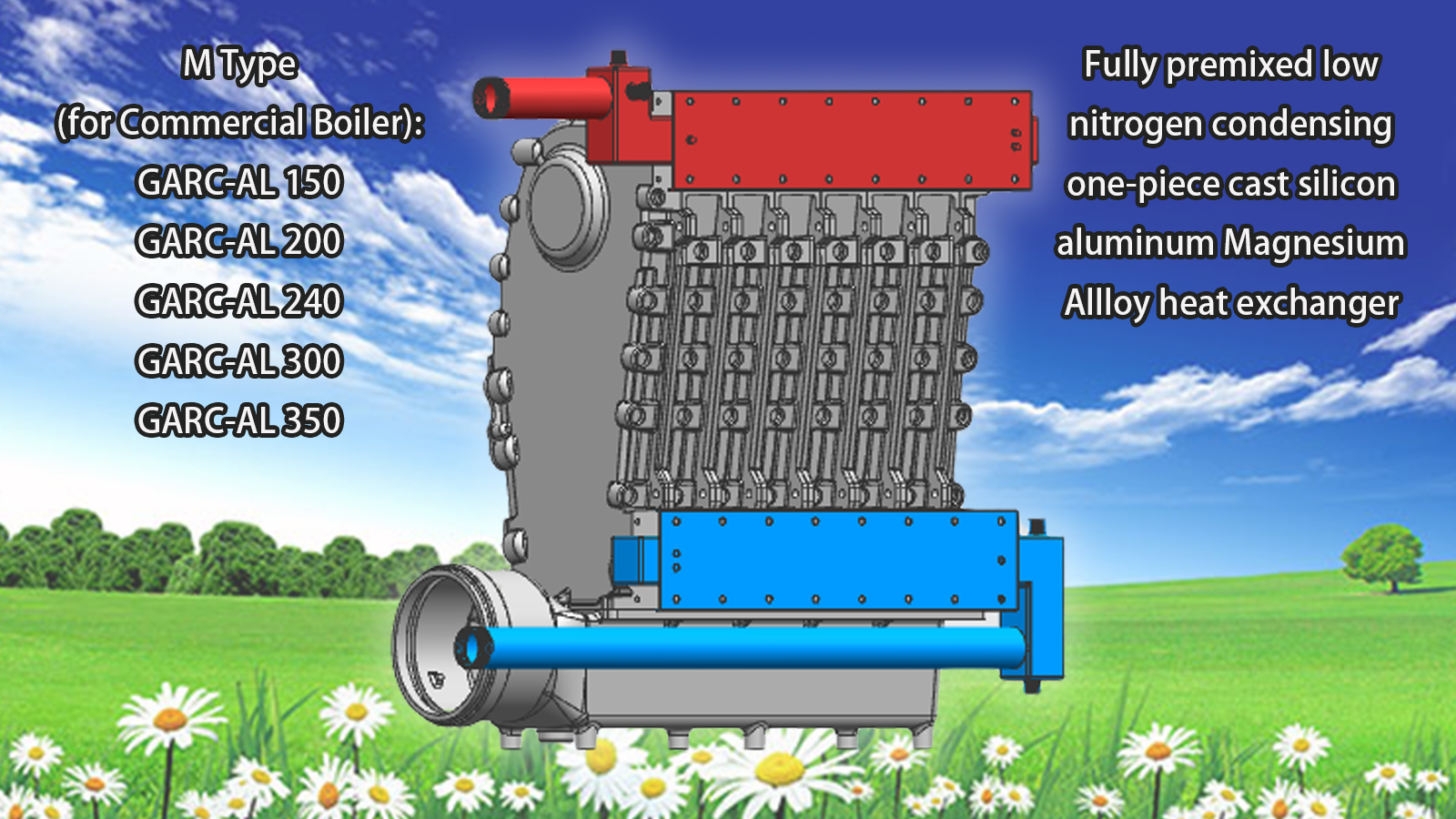

cast silicon aluminum alloy heat exchanger exporter

The Strategic Importance of Cast Silicon Aluminum Alloy Heat Exchanger Exporters

In today’s globalized economy, industries are constantly seeking efficient and innovative solutions to enhance their operations and product longevity. One such solution that has gained significant traction in various sectors, particularly in automotive and industrial equipment, is the cast silicon aluminum alloy heat exchanger. The unique properties of this material make it an ideal choice for a myriad of applications, driving demand for specialized exporters in this field.

Understanding Cast Silicon Aluminum Alloy

Cast silicon aluminum alloy is a composite material that combines aluminum with silicon, offering enhanced fluidity during the casting process. It is widely recognized for its excellent thermal conductivity, resistance to corrosion, and lightweight properties, making it suitable for heat exchangers. These characteristics allow for improved energy efficiency and reduced weight in applications ranging from automotive radiators to HVAC systems, which in turn leads to lower operational costs and improved performance.

The Role of Heat Exchangers

Heat exchangers are vital components in various industrial processes. They facilitate the transfer of heat between two or more fluids, ensuring optimal thermal management in systems such as engines, air conditioning units, and chemical processing plants. The performance of a heat exchanger largely depends on the materials used in its construction. Cast silicon aluminum alloy offers superior performance, enabling heat exchangers to operate at higher efficiencies and greater reliability.

Global Demand and Market Dynamics

The demand for cast silicon aluminum alloy heat exchangers is on the rise globally. Factors such as increasing energy efficiency regulations, growing environmental concerns, and the need for innovative cooling solutions have driven manufacturers to adopt advanced materials. Countries with robust industrial sectors, particularly in Europe, North America, and parts of Asia, are key markets for these products.

Exporters of cast silicon aluminum alloy heat exchangers play a crucial role in meeting this demand

. They not only supply high-quality products but also provide technical support and guidance to manufacturers in different regions. This enables end-users to implement effective thermal management solutions tailored to their specific requirements.Advantages of Choosing Specialized Exporters

cast silicon aluminum alloy heat exchanger exporter

Partnering with specialized exporters of cast silicon aluminum alloy heat exchangers presents numerous advantages. First, these exporters usually have extensive knowledge and experience in the industry. They are adept at developing customized solutions that cater to the unique needs of different sectors, ensuring optimal performance and compliance with local regulations.

Second, specialized exporters often have established relationships with manufacturers, which allows for smoother logistics and supply chain management. This can lead to reduced lead times, ensuring that clients receive their products when needed without compromising on quality.

Furthermore, a focus on innovation is another hallmark of specialized exporters. They invest in research and development to create state-of-the-art products that leverage the latest advancements in materials science. This commitment to innovation not only enhances product performance but also contributes to sustainability efforts by enabling more energy-efficient solutions.

Challenges in the Export Market

Despite the promising outlook for cast silicon aluminum alloy heat exchanger exporters, there are challenges that must be navigated. These include fluctuating raw material prices, stringent regulatory standards across different regions, and competition from alternative materials. Moreover, maintaining quality control across international borders can be complex, necessitating a consistent focus on quality assurance practices throughout the supply chain.

Future Trends

Looking ahead, the market for cast silicon aluminum alloy heat exchangers is expected to continue growing. The increasing integration of smart technologies in industrial processes will likely drive demand for advanced heat exchangers that can operate in tandem with these systems. Additionally, the push towards sustainability and carbon neutrality will lead to further investments in energy-efficient solutions, positioning cast silicon aluminum alloy heat exchangers as a vital component of future industrial applications.

Conclusion

In summary, the role of cast silicon aluminum alloy heat exchanger exporters is pivotal in addressing the growing demand for effective thermal management solutions. With their ability to provide high-quality, customized products and support, these exporters are well-positioned to thrive in an evolving market landscape. As industries continue to prioritize energy efficiency and sustainability, the significance of cast silicon aluminum alloy heat exchangers will undoubtedly expand, shaping the future of thermal management across various sectors.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025