- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 08, 2024 19:23 Back to list

cast silicon aluminum alloy heat exchanger factories

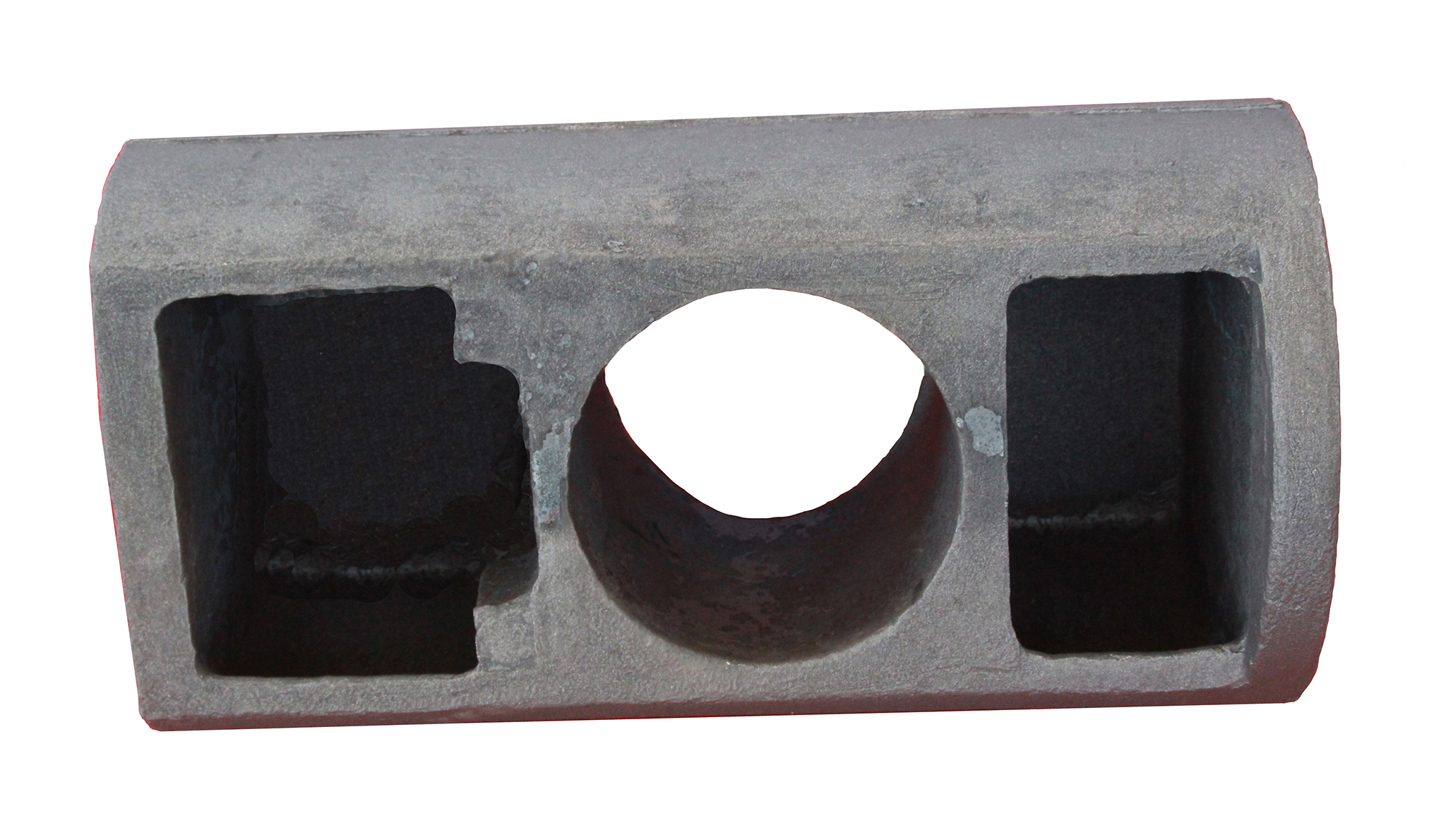

Cast Silicon Aluminum Alloy Heat Exchanger Factories An Overview

In recent years, the increasing demand for effective and efficient heat transfer solutions has driven the growth of various industries. Among the materials that have gained significant attention in the development of heat exchangers, cast silicon aluminum alloys stand out due to their advantageous properties. This article aims to provide an overview of the production and significance of cast silicon aluminum alloy heat exchangers, as well as an insight into the factories that manufacture them.

The Significance of Cast Silicon Aluminum Alloys

Cast silicon aluminum alloys are known for their excellent thermal conductivity, lightweight nature, and high resistance to corrosion. These materials exhibit superior mechanical properties that make them ideal for heat exchanger applications across various sectors, such as automotive, aerospace, and industrial manufacturing. The incorporation of silicon in aluminum alloys enhances fluidity during the casting process and improves their casting characteristics, making them suitable for intricate shapes and complex designs.

Advantages in Heat Exchanger Applications

Heat exchangers play a crucial role in numerous processes where heat needs to be transferred from one medium to another. The use of cast silicon aluminum alloy in heat exchangers offers several key advantages

1. Thermal Efficiency The high thermal conductivity of silicon aluminum alloys facilitates effective heat transfer, which is essential for maximizing energy efficiency in thermal management systems.

2. Weight Reduction Aluminum alloys, being lightweight materials, contribute to the reduction of overall system weight, which is particularly beneficial in transportation applications, such as automotive and aerospace.

4. Versatility The adaptability of cast silicon aluminum alloys allows for the production of various designs and configurations, making them suitable for a wide range of applications.

cast silicon aluminum alloy heat exchanger factories

Manufacturing Process in Factories

The production of cast silicon aluminum alloy heat exchangers typically involves several stages. Factories specializing in this field employ advanced casting techniques, such as sand casting or die casting, combined with state-of-the-art machining processes to achieve precision components.

1. Material Preparation The initial stage involves the preparation of the silicon aluminum alloy. The precise composition is crucial for achieving the desired properties, and this requires careful selection of raw materials.

2. Casting The prepared alloy is melted and poured into molds. The casting process may vary depending on the desired complexity and specifications of the heat exchangers.

3. Machining Once the cast parts cool and solidify, machining processes like milling, drilling, and surface finishing are employed to refine the components, ensuring they meet stringent dimensional and quality standards.

4. Assembly and Testing After machining, heat exchanger components are assembled, and rigorous testing is conducted to assess their performance and adherence to industry standards. This phase is critical in ensuring the reliability and efficiency of the final product.

5. Quality Control Factories implement strict quality control measures throughout the production process to guarantee that the heat exchangers meet or exceed customer specifications.

Conclusion

As industries continue to evolve and seek more efficient thermal management solutions, cast silicon aluminum alloy heat exchangers are becoming increasingly popular. Their unique properties and benefits make them a preferred choice for a variety of applications. Factories specializing in the production of these heat exchangers are pivotal in meeting the demands of modern industries, ensuring high-quality products that enhance energy efficiency and reduce operational costs. With ongoing advancements in materials science and manufacturing technologies, the future of cast silicon aluminum alloy heat exchangers looks promising, paving the way for innovations in heat transfer solutions.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025