- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 20, 2024 09:46 Back to list

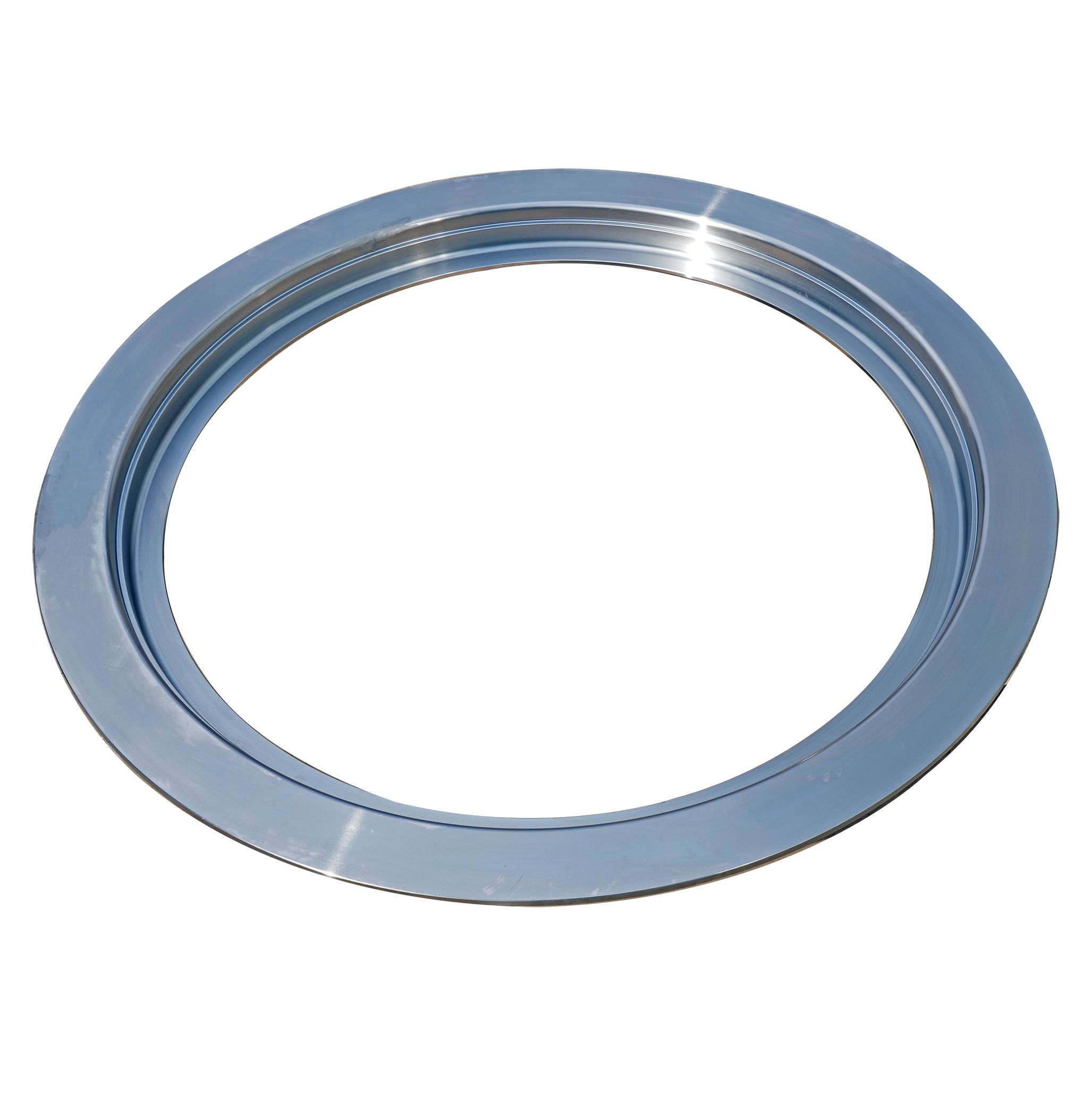

cast silicon aluminum heat exchanger for commercial heating boiler manufacturers

The Role of Cast Silicon Aluminum Heat Exchangers in Commercial Heating Boilers

In the realm of commercial heating solutions, the efficiency and effectiveness of heating boilers play a pivotal role in maintaining optimal indoor climates. One key component that significantly enhances the performance of these systems is the heat exchanger. Among various options available, cast silicon aluminum heat exchangers have gained considerable attention for their unique properties and advantages, making them an ideal choice for manufacturers of commercial heating boilers.

Understanding Heat Exchangers

Heat exchangers are vital devices that facilitate the transfer of heat between two or more fluids, without them mixing. In heating boilers, they are responsible for extracting heat from the combustion process and transferring it to the water that circulates through the system. This process is crucial for efficient heating, and the material used for manufacturing heat exchangers greatly influences their performance and longevity.

The Superiority of Cast Silicon Aluminum

Cast silicon aluminum is an innovative alloy that combines the benefits of both silicon and aluminum to produce a lightweight, durable, and corrosion-resistant material. This alloy has emerged as one of the best choices for manufacturing heat exchangers used in commercial heating boilers. Here are several reasons why manufacturers are increasingly opting for cast silicon aluminum heat exchangers.

1. Corrosion Resistance One of the most significant advantages of cast silicon aluminum is its superior resistance to corrosion. Commercial heating systems often operate under high temperature and pressure, with exposure to various compounds that can cause degradation. The corrosion resistance provided by the silicon content in the alloy ensures that the heat exchangers maintain structural integrity over time, minimizing maintenance costs and downtime.

cast silicon aluminum heat exchanger for commercial heating boiler manufacturers

2. Thermal Conductivity Cast silicon aluminum offers excellent thermal conductivity, enabling efficient heat transfer. For heating applications, efficient heat exchangers can lead to reduced energy consumption and lower operational costs. By ensuring that more heat is transferred to the water and less is lost to the environment, manufacturers can design heating systems that perform optimally.

3. Weight Efficiency Compared to traditional materials such as cast iron or stainless steel, cast silicon aluminum is significantly lighter. This characteristic allows for easier handling and installation, reducing labor costs during manufacturing and assembly. Moreover, the reduced weight can decrease the overall structural requirements for the heating system, leading to savings in both materials and project timelines.

4. Design Flexibility The casting process for silicon aluminum allows for intricate designs and configurations. Manufacturers can create more complex heat exchanger shapes that maximize surface area, leading to improved heat transfer rates. Additionally, this flexibility enables the production of customized solutions tailored to specific heating requirements, providing a competitive edge in the commercial boiler market.

5. Energy Efficiency In an era where energy efficiency is paramount, cast silicon aluminum heat exchangers contribute significantly to the performance of heating boilers. With their ability to maintain high efficiency over a long service life, they support manufacturers in meeting stringent energy regulations and sustainability goals. This relevance is particularly vital in today’s market, where consumers are increasingly concerned about energy costs and environmental impacts.

Conclusion The Future of Commercial Heating Boilers

As the demand for efficient, reliable, and environmentally friendly heating solutions continues to grow, manufacturers of commercial heating boilers increasingly recognize the advantages of using cast silicon aluminum heat exchangers. Their corrosion resistance, superior thermal conductivity, lightweight properties, design versatility, and contribution to energy efficiency position them as a cornerstone in modern heating technology.

In summary, the integration of cast silicon aluminum heat exchangers into commercial heating boiler systems represents a significant advancement in the quest for optimally performing heating solutions. With ongoing innovation in materials and design, the future of heating technology is set to become even more energy-efficient and sustainable, benefiting both manufacturers and end-users alike.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025