- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 25, 2024 06:53 Back to list

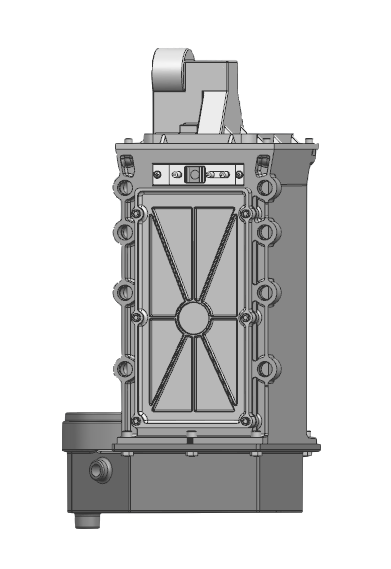

China Cement Pipe Molding Pallets Efficient Solutions for Pipe Production

Innovations in China's Cement Pipe Mold Pallet Industry Enhancing Efficiency and Sustainability

In the bustling landscape of global infrastructure development, China stands as a major player, contributing significantly to advancements in construction materials and methodologies. Among these innovations, the cement pipe mold pallet sector has witnessed remarkable growth, fueled by the country's commitment to enhancing production efficiency and promoting sustainable practices. This article delves into the recent developments in China's cement pipe mold pallet industry, exploring how technology, design improvements, and eco-friendly materials are reshaping the sector.

**Introduction to Cement Pipe Mold Pallets**

Cement pipes, widely used in sewage systems, water supply networks, and stormwater management, require precise and efficient manufacturing processes. Mold pallets play a pivotal role in this process, serving as the base on which concrete is cast, ensuring uniform shape and facilitating easy handling during and after the curing period. In China, the demand for high-quality, durable cement pipes has driven innovations in mold pallet design and material selection.

**Technological Advancements**

One of the key trends in China's cement pipe mold pallet industry is the integration of advanced manufacturing technologies. Automation and robotics have been introduced to streamline the production process, reducing labor costs and enhancing precision. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems are employed to create intricate mold designs, allowing for customization and faster turnaround times. This not only increases productivity but also ensures consistency in product quality, a critical factor in large-scale infrastructure projects.

**Material Innovations for Sustainability**

Sustainability is at the forefront of China's industrial policies, and the cement pipe mold pallet sector is no exception. Traditional wooden pallets, though widely used, have given way to more eco-friendly alternatives such as plastic, composite materials, and even recycled plastic derivatives. These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact

These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact china cement pipe mold pallet. Additionally, some manufacturers are exploring biodegradable materials, aligning with global green initiatives.

**Efficiency and Cost-effectiveness**

Efforts to enhance efficiency and cost-effectiveness are evident in the adoption of modular and interchangeable mold systems. These systems allow for quick mold changes, accommodating various pipe sizes and shapes without extensive downtime. This flexibility not only speeds up production but also reduces the need for storage space and additional equipment, translating into significant cost savings for manufacturers. Furthermore, the use of heat-resistant and non-stick coatings on mold surfaces ensures a clean release, reducing defects and the need for frequent maintenance.

**Quality Control and Standardization**

As China's cement pipe mold pallet industry matures, adherence to strict quality control measures and international standards becomes crucial. The implementation of ISO certifications and adherence to national standards ensure that products meet or exceed global benchmarks for durability, safety, and performance. This focus on standardization not only bolsters China's reputation as a reliable supplier in the global market but also facilitates international trade by harmonizing product specifications.

**Conclusion**

China's cement pipe mold pallet industry is a testament to the nation's drive for innovation and sustainability. By embracing technological advancements, adopting eco-friendly materials, and emphasizing efficiency, manufacturers are not just meeting the growing domestic demand but also positioning themselves as global leaders in the sector. As infrastructure development continues worldwide, China's contributions in enhancing the production of cement pipes through advanced mold pallet solutions will undoubtedly play a vital role in shaping resilient and sustainable infrastructure for future generations.

china cement pipe mold pallet. Additionally, some manufacturers are exploring biodegradable materials, aligning with global green initiatives.

**Efficiency and Cost-effectiveness**

Efforts to enhance efficiency and cost-effectiveness are evident in the adoption of modular and interchangeable mold systems. These systems allow for quick mold changes, accommodating various pipe sizes and shapes without extensive downtime. This flexibility not only speeds up production but also reduces the need for storage space and additional equipment, translating into significant cost savings for manufacturers. Furthermore, the use of heat-resistant and non-stick coatings on mold surfaces ensures a clean release, reducing defects and the need for frequent maintenance.

**Quality Control and Standardization**

As China's cement pipe mold pallet industry matures, adherence to strict quality control measures and international standards becomes crucial. The implementation of ISO certifications and adherence to national standards ensure that products meet or exceed global benchmarks for durability, safety, and performance. This focus on standardization not only bolsters China's reputation as a reliable supplier in the global market but also facilitates international trade by harmonizing product specifications.

**Conclusion**

China's cement pipe mold pallet industry is a testament to the nation's drive for innovation and sustainability. By embracing technological advancements, adopting eco-friendly materials, and emphasizing efficiency, manufacturers are not just meeting the growing domestic demand but also positioning themselves as global leaders in the sector. As infrastructure development continues worldwide, China's contributions in enhancing the production of cement pipes through advanced mold pallet solutions will undoubtedly play a vital role in shaping resilient and sustainable infrastructure for future generations.

These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact

These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact These materials offer longer lifespans, reduced weight for easier handling, and importantly, they are recyclable, thereby minimizing waste and environmental impact china cement pipe mold pallet. Additionally, some manufacturers are exploring biodegradable materials, aligning with global green initiatives.

**Efficiency and Cost-effectiveness**

Efforts to enhance efficiency and cost-effectiveness are evident in the adoption of modular and interchangeable mold systems. These systems allow for quick mold changes, accommodating various pipe sizes and shapes without extensive downtime. This flexibility not only speeds up production but also reduces the need for storage space and additional equipment, translating into significant cost savings for manufacturers. Furthermore, the use of heat-resistant and non-stick coatings on mold surfaces ensures a clean release, reducing defects and the need for frequent maintenance.

**Quality Control and Standardization**

As China's cement pipe mold pallet industry matures, adherence to strict quality control measures and international standards becomes crucial. The implementation of ISO certifications and adherence to national standards ensure that products meet or exceed global benchmarks for durability, safety, and performance. This focus on standardization not only bolsters China's reputation as a reliable supplier in the global market but also facilitates international trade by harmonizing product specifications.

**Conclusion**

China's cement pipe mold pallet industry is a testament to the nation's drive for innovation and sustainability. By embracing technological advancements, adopting eco-friendly materials, and emphasizing efficiency, manufacturers are not just meeting the growing domestic demand but also positioning themselves as global leaders in the sector. As infrastructure development continues worldwide, China's contributions in enhancing the production of cement pipes through advanced mold pallet solutions will undoubtedly play a vital role in shaping resilient and sustainable infrastructure for future generations.

china cement pipe mold pallet. Additionally, some manufacturers are exploring biodegradable materials, aligning with global green initiatives.

**Efficiency and Cost-effectiveness**

Efforts to enhance efficiency and cost-effectiveness are evident in the adoption of modular and interchangeable mold systems. These systems allow for quick mold changes, accommodating various pipe sizes and shapes without extensive downtime. This flexibility not only speeds up production but also reduces the need for storage space and additional equipment, translating into significant cost savings for manufacturers. Furthermore, the use of heat-resistant and non-stick coatings on mold surfaces ensures a clean release, reducing defects and the need for frequent maintenance.

**Quality Control and Standardization**

As China's cement pipe mold pallet industry matures, adherence to strict quality control measures and international standards becomes crucial. The implementation of ISO certifications and adherence to national standards ensure that products meet or exceed global benchmarks for durability, safety, and performance. This focus on standardization not only bolsters China's reputation as a reliable supplier in the global market but also facilitates international trade by harmonizing product specifications.

**Conclusion**

China's cement pipe mold pallet industry is a testament to the nation's drive for innovation and sustainability. By embracing technological advancements, adopting eco-friendly materials, and emphasizing efficiency, manufacturers are not just meeting the growing domestic demand but also positioning themselves as global leaders in the sector. As infrastructure development continues worldwide, China's contributions in enhancing the production of cement pipes through advanced mold pallet solutions will undoubtedly play a vital role in shaping resilient and sustainable infrastructure for future generations. Share

Latest news

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025