- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 17, 2024 06:08 Back to list

China Concrete Pipe Mould Pallet for Efficient Pipe Production and Quality Control

The Importance of Concrete Pipe Mould Pallets in China’s Construction Industry

Concrete pipe mould pallets play a pivotal role in the construction industry, especially in China, where rapid urbanization and infrastructure development are ongoing. These pallets are integral to the manufacturing process of concrete pipes, which are widely used in various civil engineering applications such as drainage systems, sewage systems, and water supply networks. The production of high-quality concrete pipes requires precision moulds and reliable pallets, making them essential components in the construction materials supply chain.

Understanding Concrete Pipe Mould Pallets

Concrete pipe mould pallets are specialized platforms designed to support the moulds used in the casting of concrete pipes. Typically made from steel or durable plastics, these pallets are engineered to withstand the heavy weight of the concrete and the stresses involved during the curing and setting process. The pallets provide a stable base that ensures the moulds maintain their shape, resulting in uniform and high-quality concrete products.

Advantages of Using Quality Pallets

1. Durability and Longevity High-quality mould pallets are built to last. In an industry where turnaround times are crucial, durable pallets minimize downtime caused by wear and tear. Investing in superior pallets can significantly enhance production efficiency and reduce replacement costs over time.

2. Enhanced Precision The structural integrity of the pallets directly affects the quality of the concrete pipes produced. By ensuring that moulds remain stable and aligned during casting, high-quality pallets contribute to better dimensional accuracy and consistency in the final product.

3. Cost-Effectiveness Although the initial investment in high-quality pallets might be higher, the long-term savings are significant. Durable pallets reduce the frequency of replacements and maintenance, leading to lower overall operational costs. Furthermore, enhanced production efficiency translates to better profitability for manufacturers.

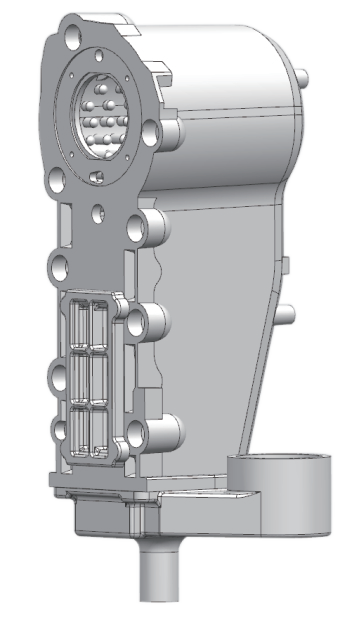

china punching concrete pipe mould pallet

The Role of Technology in Manufacturing Pallets

In recent years, the technology involved in the production of concrete pipe mould pallets has evolved considerably. Automated processes and advanced materials have improved the quality and consistency of the pallets. Techniques such as precision machining and high-quality surface treatments have become standard to ensure that pallets can resist abrasion and chemical exposure from the concrete.

Moreover, innovations in design have led to the development of pallets with interlocking features that increase stability and ease of handling. The integration of technological advancements not only improves the functionality of the pallets but also aligns with modern manufacturing practices that prioritize efficiency and sustainability.

China’s Growing Demand for Concrete Pipe Mould Pallets

As one of the world’s largest construction markets, China’s demand for concrete pipe mould pallets continues to rise. With ambitious infrastructure projects, including roads, railways, and bridges, the need for reliable concrete pipes is more pressing than ever. Consequently, manufacturers are continually seeking innovative solutions to enhance their production capabilities, which drives the demand for high-quality mould pallets.

Conclusion

Concrete pipe mould pallets are critical to the construction industry in China, directly impacting the quality, efficiency, and cost-effectiveness of concrete pipe production. With ongoing technological advancements and the growing demand for infrastructure development, the significance of these pallets will only increase. By investing in durable and efficient mould pallets, manufacturers can ensure they meet the rising expectations of a changing market while contributing to the robust growth of China’s construction sector.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025