- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 20, 2024 18:49 Back to list

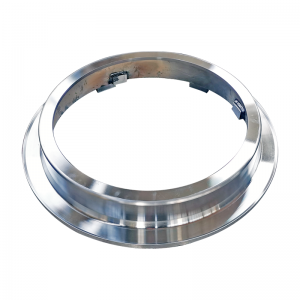

China Concrete Pipe Mould Production with Bottom Ring for Enhanced Durability

China Punching Concrete Pipe Mould Bottom Ring A Crucial Component in Construction

In the world of construction, particularly in the production of concrete pipes, the importance of quality moulds cannot be overstated. Among the various components that contribute to the efficient manufacture of concrete pipes, the punching concrete pipe mould bottom ring stands out as a vital element. This article explores the significance of these mould bottom rings, their manufacturing processes in China, and their impact on the overall quality of concrete piping.

Concrete pipes are widely used in infrastructure projects, including sewage systems, drainage, and irrigation. The durability and strength of these pipes are crucial for ensuring that they withstand the test of time and environmental conditions. A well-designed mould is essential for producing concrete pipes that meet industry standards, and the bottom ring plays a significant role in this process.

The punching concrete pipe mould bottom ring is designed to shape the bottom of the pipe and ensure that it achieves the necessary thickness and structural integrity. This component is typically made from high-quality steel or durable materials that can withstand the high pressures and temperatures involved in the concrete curing process. In China, manufacturers have honed their techniques and technologies to produce moulds that not only meet domestic standards but also adhere to international quality norms.

One of the key advantages of sourcing punching concrete pipe mould bottom rings from China is the advanced manufacturing technology available. Chinese manufacturers utilize state-of-the-art machinery and precision engineering to create moulds that facilitate the efficient production of concrete pipes. This helps reduce waste, minimize production time, and ensure consistency in pipe quality. The use of computer-aided design (CAD) allows for precise measurements, which are critical for achieving the required specifications.

china punching concrete pipe mould bottom ring

Moreover, the competitive pricing offered by Chinese manufacturers makes it economically viable for companies worldwide to procure these essential components. With lower production costs and high-quality output, Chinese moulds have gained popularity in international markets. This influx of cost-effective solutions has also prompted local manufacturers in other countries to improve their product offerings in a bid to remain competitive.

In addition to ensuring quality and durability, the design of punching concrete pipe mould bottom rings is also evolving to incorporate innovative features. Many manufacturers are now focusing on sustainable practices, creating moulds that are not only efficient but also environmentally friendly. This includes the use of recyclable materials and processes that minimize energy consumption and waste generation.

The use of punching concrete pipe mould bottom rings directly impacts the performance of concrete pipes in various applications. Well-constructed pipes provide better flow characteristics, reduced leakage rates, and enhanced structural integrity. These factors contribute to the longevity of infrastructure projects, ultimately leading to lower maintenance costs and fewer disruptions in service.

As global demands for infrastructure continue to rise, the role of high-quality mould components, like the punching concrete pipe mould bottom ring, becomes increasingly critical. Companies seeking to optimize their production processes and enhance the quality of their products will find that investing in superior mould technology is an essential strategy. By leveraging the expertise of Chinese manufacturers, businesses can achieve significant improvements in efficiency and output, ensuring that they remain competitive in a rapidly evolving marketplace.

In conclusion, the punching concrete pipe mould bottom ring is an essential component in the production of high-quality concrete pipes. As a cornerstone of modern construction practices, it exemplifies the advancements in manufacturing technology and the growing importance of sustainability in the industry. By embracing these innovations, companies can ensure the durability and effectiveness of their infrastructure projects for years to come.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025