- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 05, 2024 23:42 Back to list

china cast iron pipe mould palet

The Significance of China’s Cast Iron Pipe Mould Palet in the Industrial Sector

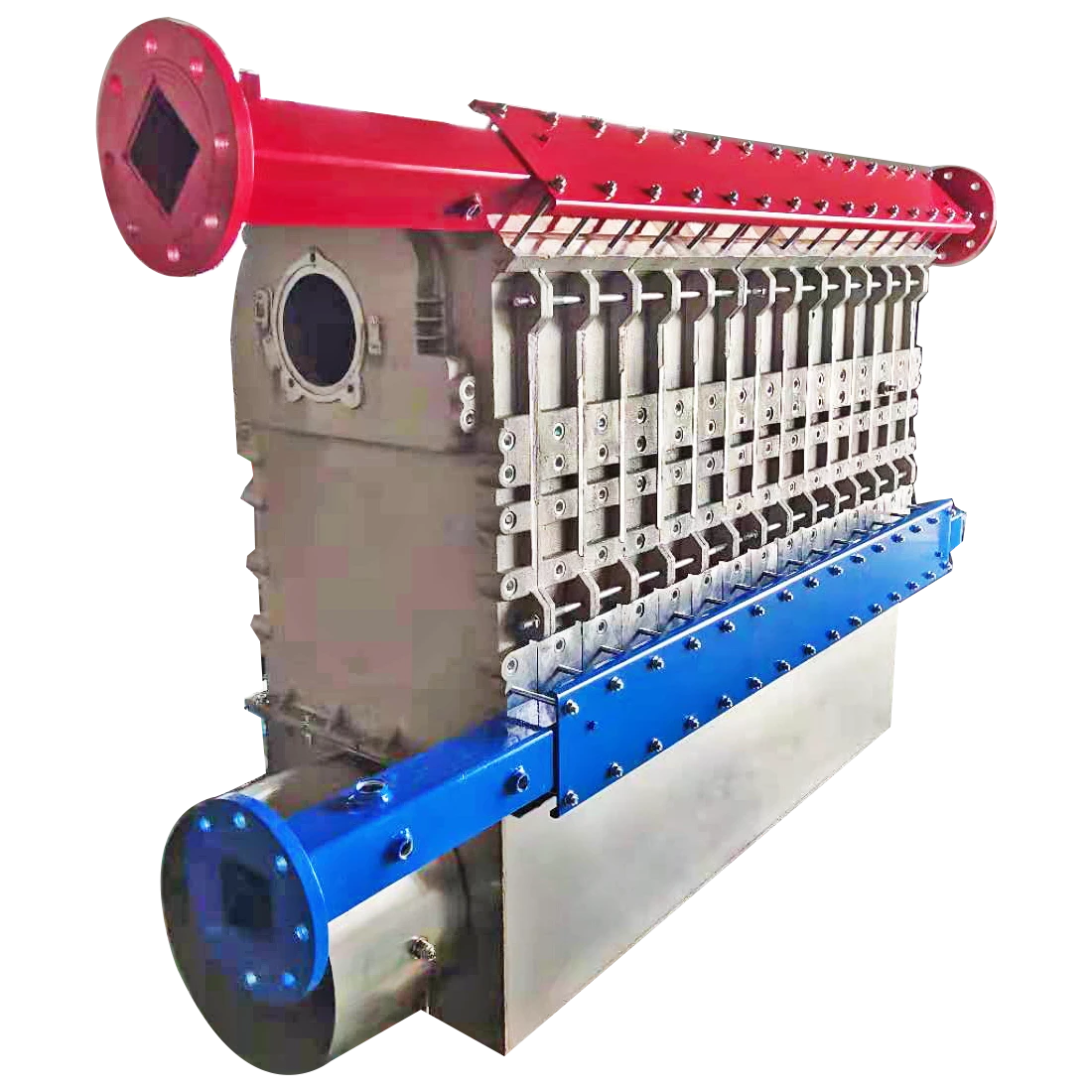

In the ever-evolving industrial landscape, the demand for high-quality materials and efficient production processes is paramount. One significant element in the manufacturing of cast iron pipes is the use of mould palets. These are instrumental in shaping and forming pipes that are essential for various applications, such as plumbing, drainage, and gas systems. China, a global leader in manufacturing, has gained a reputation for producing efficient and reliable cast iron pipe mould palets that are crucial to the pipeline industry.

Understanding Cast Iron Pipe Mould Palets

A mould palet serves as a container or framework within which molten iron is poured to create specific shapes and sizes of pipes. The design of these palets is pivotal as it ensures that the castings are uniform and of high quality. In the context of cast iron pipes, the mould palet must withstand high temperatures and exert significant force during the casting process. Chinese manufacturers have leveraged advanced technology, skilled labor, and quality materials to produce mould palets that meet international standards.

China’s Competitive Edge

China's supremacy in the production of cast iron pipe mould palets can be attributed to several factors. Firstly, the country's robust industrial infrastructure allows for mass production at competitive prices. The availability of raw materials combined with efficient logistics ensures that manufacturers can meet both domestic and international demands promptly.

Secondly, the vast labor pool in China, coupled with ongoing training and upskilling programs, enhances the quality of workmanship

. Chinese artisans and engineers work meticulously to improve mould designs, ensuring they provide precise specifications while maximizing durability and longevity.Moreover, the incorporation of cutting-edge technology in casting processes, such as computer-aided design (CAD) and automated machinery, has further streamlined production. This technological advancement reduces human error, improves efficiency, and enables manufacturers to produce complex mould designs that were previously not feasible.

china cast iron pipe mould palet

Environmental Considerations

As the world moves toward more environmentally sustainable practices, Chinese manufacturers are also increasingly focusing on eco-friendly production methods. The cast iron production process typically involves high energy consumption and emissions. However, many manufacturers in China are adopting greener technologies and practices, including recycling systems that reduce waste and lower carbon footprints.

Furthermore, the use of high-quality iron ore in producing cast iron reduces the need for frequent replacements of mould palets, thus contributing to a more sustainable operation in the long run. By focusing on reducing environmental impact while maintaining quality, Chinese manufacturers are aligning their production methods with global sustainability goals.

The Global Impact of Chinese Mould Palets

The influence of China’s cast iron pipe mould palets extends beyond its shores. Countries across the globe rely on Chinese manufacturers for their quality and cost-effectiveness. This reliance has led to the establishment of long-term partnerships between Chinese firms and international customers, fostering trade relationships and enhancing the global supply chain.

Additionally, with the Belt and Road Initiative, China's influence in the construction and infrastructure sectors is expected to grow, particularly in developing nations. As these countries invest in their infrastructure, the demand for high-quality cast iron pipes and corresponding mould palets is likely to increase significantly.

Conclusion

In conclusion, the role of China’s cast iron pipe mould palet in the industrial sector is both vital and multifaceted. By combining competitive pricing, advanced technology, and a commitment to sustainability, China has positioned itself as a leader in the global market for cast iron pipe mould palets. As the demand for infrastructure development continues to soar worldwide, the significance of these moulds will undoubtedly expand, driving further innovation and excellence within the industry. The future of cast iron pipes is intertwined with the advancements and practices of Chinese manufacturers, making them key players in shaping the infrastructure of tomorrow.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025