- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 11, 2024 21:02 Back to list

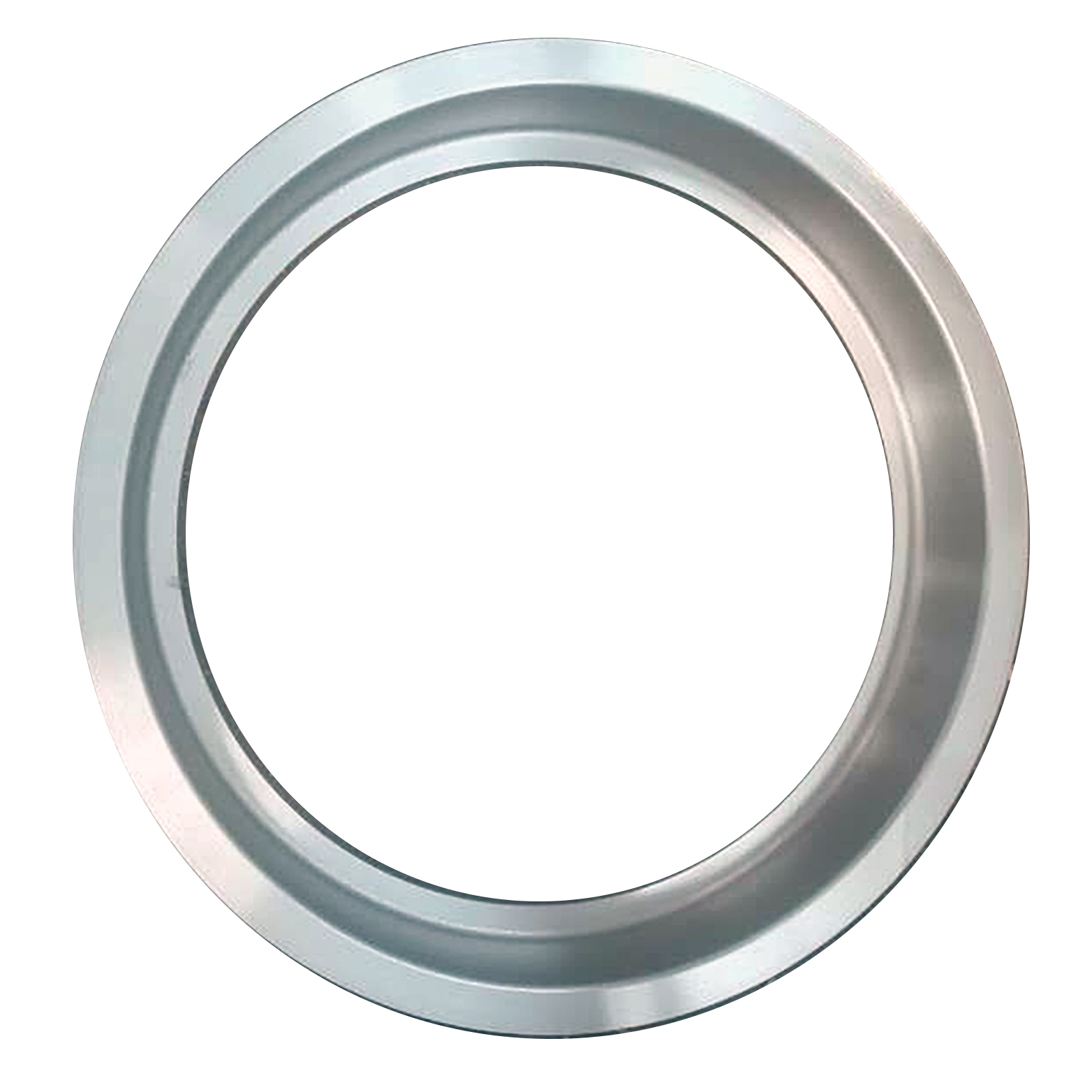

China's Durable Cast Iron Pipe Mold Pallet for Enhanced Production Efficiency and Quality

The Essential Role of Cast Iron Pipe Mold Pallets in Modern Manufacturing

In the realm of industrial manufacturing, particularly in the production of cast iron pipes, the role of specialized equipment cannot be overstated. One such crucial component is the cast iron pipe mold pallet. These pallets are essential in providing a stable and efficient work surface for the casting process, significantly enhancing both productivity and product quality.

Understanding Cast Iron Pipe Mold Pallets

Cast iron pipe mold pallets are designed specifically for the manufacturing of cast iron pipes. These pallets serve as the base where the molds are placed during the casting process. Typically made from durable materials themselves, these pallets are engineered to withstand the high pressures and temperatures involved in casting operations. Their design ensures that the molds remain secure and correctly aligned, which is vital for producing pipes that meet precise dimensional specifications.

The Manufacturing Process and the Role of Pallets

The manufacturing process for cast iron pipes involves several steps, including molding, pouring, cooling, and finishing. At the heart of this process lies the mold pallet. During the initial phase, the mold is created by pouring a mixture of sand, clay, and water into a form. The mold is then placed on the pallet, which provides the structural integrity needed to support the weight of the poured molten iron.

Once the iron is poured into the mold and allowed to cool, the design of the pallet ensures that the mold can be easily handled without risk of damage. After the pipes are cast and removed from their molds, the pallets facilitate easy transportation of the molds through different stages of the manufacturing process, enhancing overall efficiency.

china cast iron pipe mold pallet

Quality and Durability

Quality is paramount in the casting industry. Faulty molds can lead to defective pipes, which may not meet industry standards or safety regulations. Cast iron pipe mold pallets are engineered for durability and precision. High-quality pallets help in maintaining consistent temperatures during the cooling process, which is crucial for preventing defects such as warping or cracking in the final product. Furthermore, as manufacturing operations often run 24/7, the longevity of these pallets means reduced replacement costs and downtime for manufacturers.

Automation and Technological Advancements

As the manufacturing industry evolves, so too do the technologies used in production. Automation is increasingly becoming a staple in the casting of iron pipes, and pallet systems are being designed to integrate with automated handling equipment. This advancement allows for faster and more efficient operations, where pallets can be moved in and out of the casting area automatically. Such innovation not only improves productivity but also enhances workplace safety by reducing the manual handling of heavy molds.

Conclusion

In conclusion, cast iron pipe mold pallets are an indispensable part of the manufacturing process for cast iron pipes. Their role in providing stability, support, and efficiency cannot be ignored. As the industry continues to embrace technological advancements, the evolution of mold pallets will likely keep pace, ensuring that manufacturers can meet the increasing demands for high-quality cast iron products. Investing in high-quality mold pallets not only improves production efficiency but also contributes to the overall quality of the final product, reinforcing their status as a cornerstone in the manufacturing of cast iron pipes.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025