Nov . 18, 2024 15:12 Back to list

Custom Concrete Pipe Mold Pallet Manufacturing Original Sale Factory Solutions

Custom Concrete Pipe Mold Pallet Factory Original Sales and Innovations

In the evolving landscape of construction and infrastructure, the demand for durable and efficient materials has led to significant innovations in concrete production. Among these innovations are custom concrete pipe molds and pallets, essential for creating high-quality precast concrete pipes. This article delves into the significance of custom molds in the concrete industry, particularly focusing on factory innovations that enhance original sales.

Concrete pipes are vital in various applications, including sewage systems, drainage, and water transportation. The accuracy and quality of these pipes heavily depend on the molds used in their manufacturing. Custom concrete pipe molds enable manufacturers to tailor their products to meet specific project requirements, ensuring optimal performance and longevity. Consequently, investing in advanced, high-performance molds can lead to significant savings over time, reducing material waste and improving the production process.

A reputable factory specializing in custom concrete pipe molds plays a crucial role in this sector. These factories not only provide a broad spectrum of mold designs but also offer consultation services to help clients select the most suitable options for their needs. By understanding the technical specifications and regulatory requirements of various projects, these factories can create molds that meet industry standards while also allowing for flexibility in design.

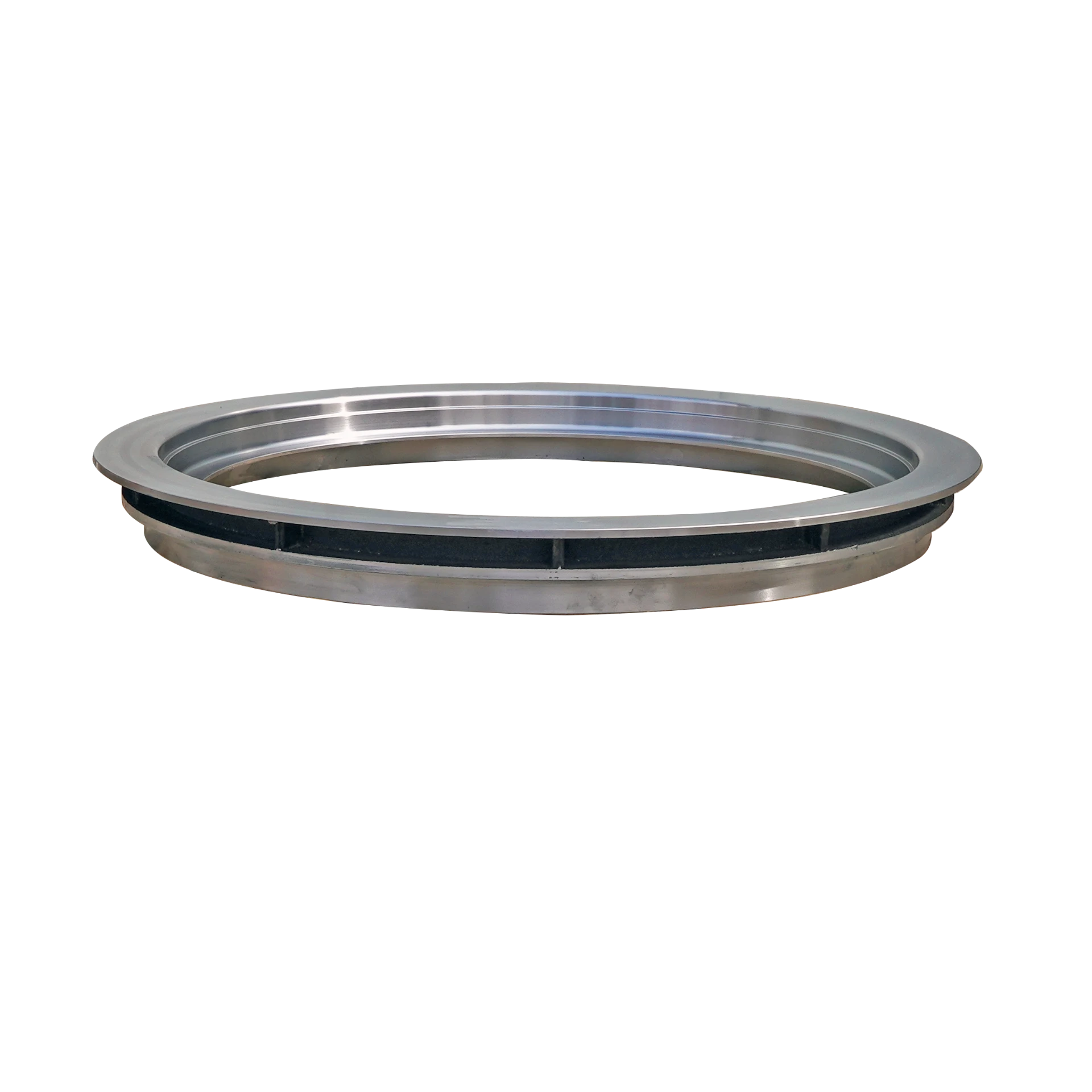

custom concrete pipe mold pallet factory original sale

The original sales strategy of these factories reflects their focus on quality and customer satisfaction. Providing comprehensive support throughout the purchasing process—from mold selection to post-sale services—ensures that customers receive value beyond the initial purchase. Factories often showcase their capabilities through detailed catalogs, online platforms, and industry exhibitions, where potential clients can assess the quality of their products firsthand.

Another aspect that underpins the success of custom concrete pipe mold factories is their commitment to innovation. Many leading manufacturers invest heavily in research and development, exploring new materials and technologies that enhance the durability and functionality of their molds. These innovations not only benefit the production process but also help in reducing the environmental impact of concrete production, aligning with global sustainability goals.

Moreover, the trend towards automation in manufacturing has led to the emergence of highly efficient production lines within these factories. By integrating advanced machinery and robotics, factories can ensure consistent quality and faster turnaround times for custom orders. This adaptability is crucial in a market that increasingly demands quick delivery without compromising on quality.

In conclusion, the custom concrete pipe mold pallet factory plays a pivotal role in enhancing the construction industry's capacity to deliver high-quality infrastructure solutions. With a strong focus on original sales, innovation, and customer satisfaction, these factories not only meet the contemporary demands of the market but also pave the way for sustainable construction practices that benefit both clients and the environment. Investing in custom molds is not merely a choice; it is a strategic decision that can lead to long-term success in any concrete undertaking.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025