Nov . 18, 2024 14:48 Back to list

Manufacturers of Bottom Rings for Punching Concrete Pipe Molds and Related Equipment

Punching Concrete Pipe Mould Bottom Ring Manufacturers An Overview

In the construction and infrastructure industry, the production of concrete pipes is essential for efficient drainage, sewage systems, and water transport. One of the key components in manufacturing these pipes is the mould—specifically, the bottom ring of the concrete pipe mould. This article delves into the role and importance of punching concrete pipe mould bottom ring manufacturers, the processes they employ, and the significance of their products in the industry.

The Role of Bottom Rings in Concrete Pipe Moulds

The bottom ring of a concrete pipe mould is a critical component that helps shape the concrete pipe during the casting process. It ensures that the pipe maintains its structural integrity and achieves the desired specifications. The bottom ring must be robust enough to withstand the weight and pressure of the concrete mixture while also providing a precise fit that aids in creating a smooth, uniform surface on the finished pipe.

Moreover, a well-designed bottom ring contributes to the overall efficiency of the production process. It streamlines the removal of the finished pipe from the mould, reducing the risk of damage and minimizing time spent on production. As a result, the bottom ring directly impacts the quality of the concrete pipes produced, which in turn affects the longevity and reliability of the infrastructure projects they serve.

Manufacturing Processes

Punching concrete pipe mould bottom rings are typically manufactured using various techniques, including forging, casting, and machining. Each method has its advantages and is chosen based on factors such as material properties, production volume, and cost efficiency.

1. Forging This process involves shaping the metal using compressive forces. Forged bottom rings are known for their high strength and durability, making them ideal for heavy-duty applications.

2. Casting This technique employs molten metal poured into a mould. While casting can be more cost-effective for small production runs, it may result in slightly less strength compared to forged products.

3. Machining For precision applications, machining is often used to create bottom rings with exact dimensions and specifications. This process can complement either forged or cast rings, allowing manufacturers to achieve tight tolerances.

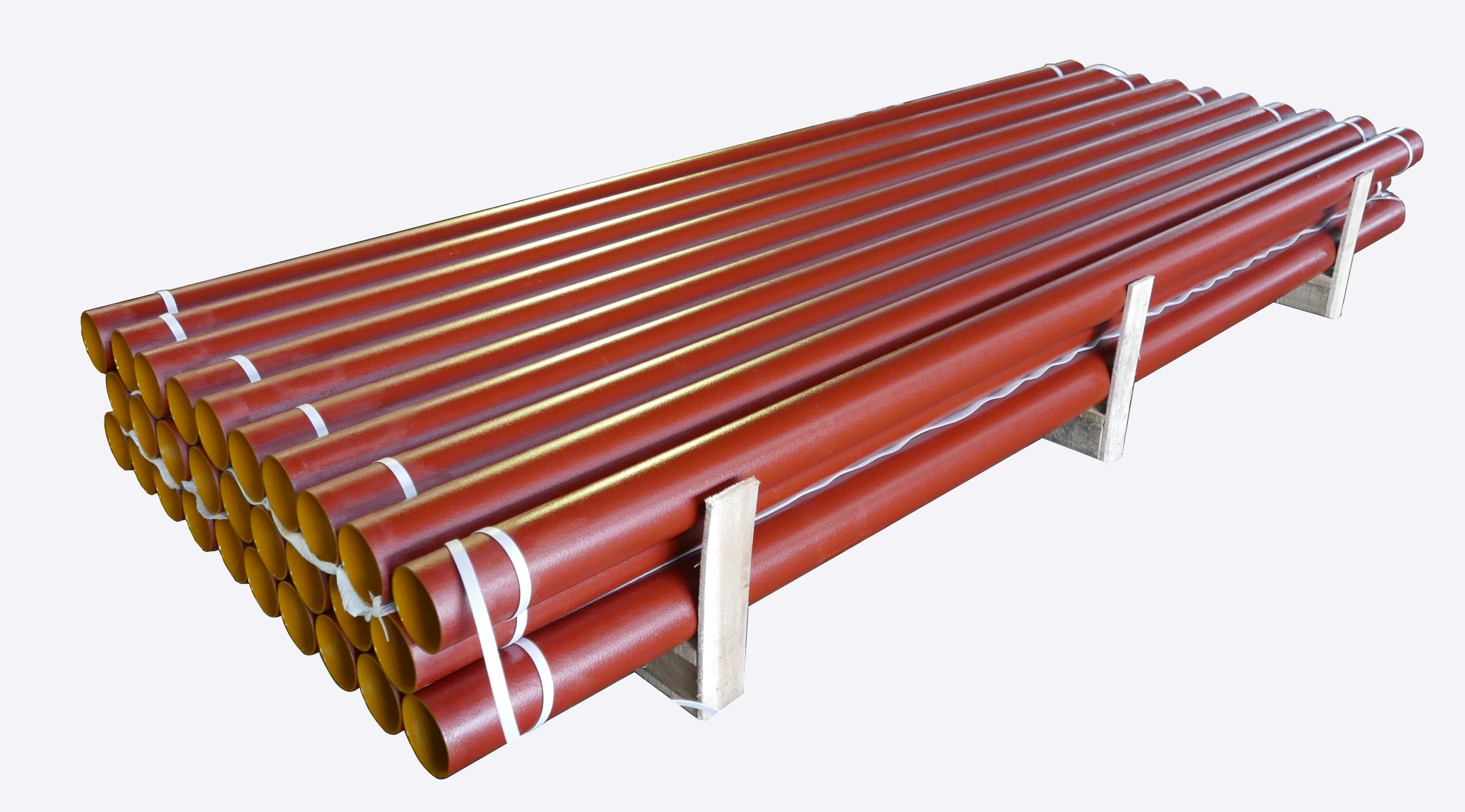

punching concrete pipe mould bottom ring manufacturers

Quality Control and Standards

Quality control is paramount in the manufacturing of punching concrete pipe mould bottom rings. Manufacturers must adhere to strict industry standards to ensure that their products meet safety and performance requirements. Regular inspection and testing during production help identify any defects and maintain consistency in the final output.

Manufacturers often work with various grades of steel and other materials to provide options that cater to different project requirements. Additionally, customized solutions can be offered, allowing clients to specify particular dimensions or features that align with their unique needs.

The Importance of Choosing the Right Manufacturer

Selecting the right manufacturer for punching concrete pipe mould bottom rings can significantly influence the success of a construction project. Factors to consider include

- Experience and Expertise Manufacturers with a solid track record in the industry are often more reliable and capable of delivering high-quality products.

- Reputation Client testimonials and industry recognition can provide insight into the manufacturer’s commitment to quality and service.

- Technology and Innovation Companies that invest in modern technologies and techniques are more likely to produce cutting-edge products.

In conclusion, punching concrete pipe mould bottom ring manufacturers play a critical role in the construction sector, ensuring that concrete pipes are produced efficiently and to exacting standards. By understanding the intricacies of their manufacturing processes and the importance of quality control, industry professionals can better appreciate the significance of these components in building reliable infrastructure.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025