- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 05, 2024 16:46 Back to list

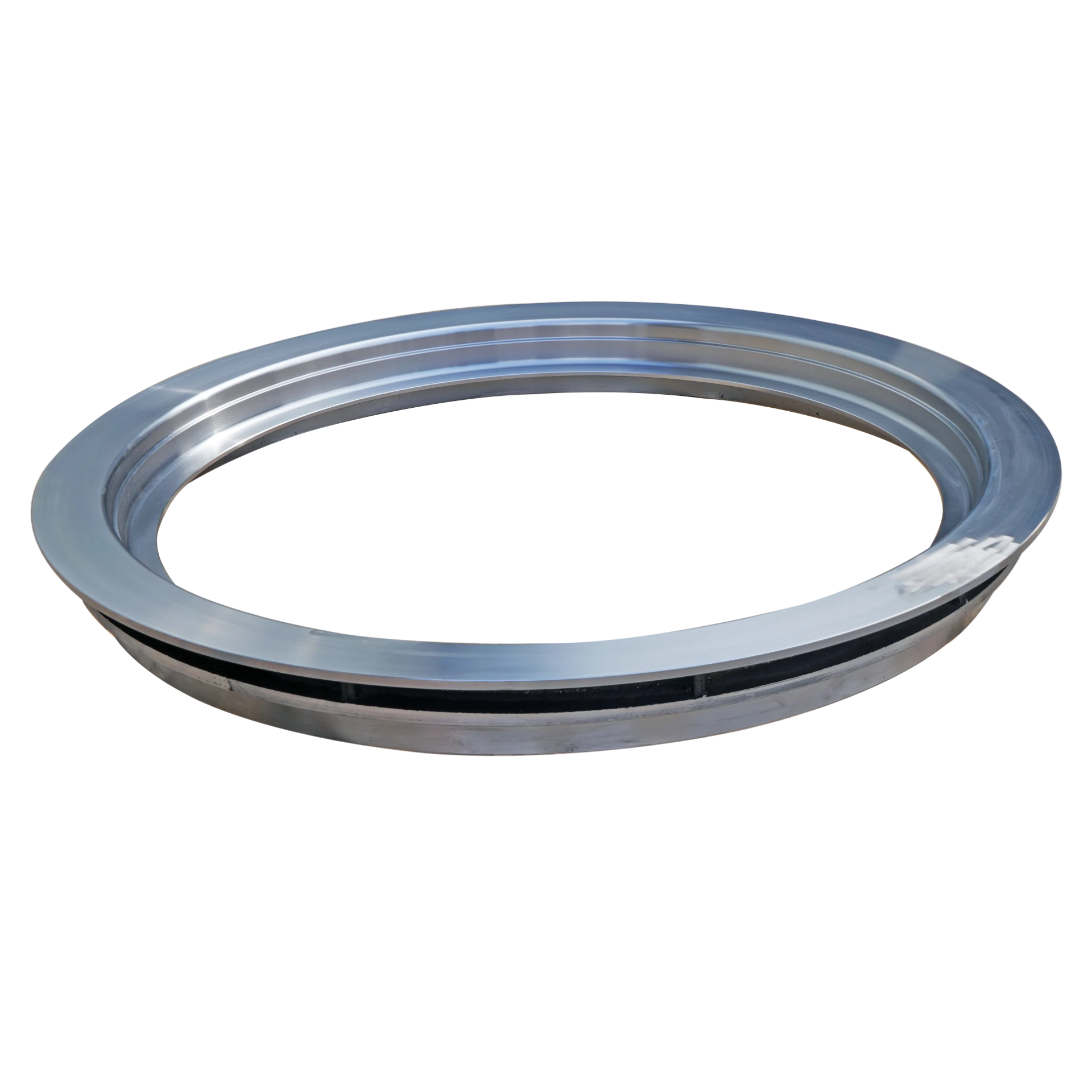

Custom Gray Iron Casting Solutions for Enhanced Performance and Durability in Various Applications

Custom Gray Iron Casting An Overview

Gray iron casting is a widely used manufacturing process that involves pouring molten gray iron into a mold to create a variety of components for numerous applications. This versatile material has become a staple in industries such as automotive, aerospace, machinery, and construction due to its excellent mechanical properties, castability, and cost-effectiveness. Custom gray iron casting, therefore, plays a crucial role in meeting the specific needs of different projects and industries.

Characteristics of Gray Iron

Gray iron is characterized by its high carbon content, which typically ranges between 2.5% to 4%. This composition results in the formation of graphite flakes within the iron matrix, giving gray iron its distinctive gray appearance and contributing to several key properties. The presence of graphite imparts excellent machinability, good wear resistance, and enhanced damping capacity, making gray iron an ideal choice for components that require both strength and durability.

Moreover, gray iron's castability allows for intricate designs and precise dimensions, making it suitable for a wide range of applications. Whether it’s engine blocks, pipe fittings, or heavy machinery parts, custom gray iron casting ensures that the final products meet stringent industry standards and performance requirements.

The Custom Casting Process

The custom gray iron casting process typically involves several steps, starting from design to production. The first phase is designing the component, which usually employs computer-aided design (CAD) software. Accurate designing is critical to ensure that the mold can be produced with precision to replicate the desired specifications of the final product.

Once the design is finalized, a mold is created. Molds can be made from a variety of materials, including sand, metal, or other composites, depending on the specific requirements of the casting. The chosen material influences the durability and lifespan of the mold, as well as the surface quality of the cast product.

custom gray iron casting

After the mold is ready, molten gray iron is poured into it. This requires careful temperature management, as the metal typically needs to be heated to around 1,200°C to 1,500°C (2,192°F to 2,732°F) to achieve a superfluid state. Proper pouring techniques are essential for avoiding defects, such as air pockets or cold shuts, which can compromise the integrity of the finished part.

Once the molten iron has cooled and solidified, the mold is removed, and the casting is cleaned and finished. Additional machining processes may be implemented to achieve the required tolerances and surface finishes.

Applications of Custom Gray Iron Castings

The applications of custom gray iron castings are vast and encompass many sectors. In the automotive industry, for instance, gray iron is commonly used for engine components such as crankshafts and cylinder heads due to its high wear resistance and ability to dissipate heat effectively. In machinery, gray iron casings and housing provide durability and stability, ensuring long operational life.

Furthermore, the construction industry benefits from custom gray iron castings in the form of manhole covers, pipe fittings, and structural components that need to withstand heavy loads and environmental stresses.

Conclusion

Custom gray iron casting is an invaluable component of modern manufacturing. Its unique characteristics make it suitable for a diverse array of applications, ensuring that various industries can meet stringent performance demands while maintaining cost efficiency. With advancements in casting technologies and processes, the future of custom gray iron casting looks promising, continually adapting to meet the evolving needs of the marketplace. Whether one is seeking high-performance automotive components or durable construction materials, custom gray iron casting offers a reliable solution for quality and functionality.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025