- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 28, 2024 14:00 Back to list

Enhanced Sodium Silicate Sand Casting Techniques for Custom Applications and Improved Performance

Custom Sodium Silicate Sand Casting Revolutionizing Foundry Practices

In the realm of metal casting, the continuous pursuit of efficiency, precision, and sustainability drives innovations that redefine traditional practices. One such innovative technique gaining traction in foundry operations is the use of custom sodium silicate sand casting. This method, which utilizes sodium silicate as a binder for sand, presents numerous benefits over conventional casting techniques, offering improved properties and outcomes for manufacturers and clients alike.

The Fundamentals of Sodium Silicate Sand Casting

Sodium silicate, often referred to as water glass, is a versatile chemical compound commonly used in various industrial applications. In the context of sand casting, it serves as a chemical binder that when mixed with sand forms a rigid mold. The process typically involves mixing dry sand with sodium silicate and a catalyst (commonly carbon dioxide), which quickly hardens the mixture into a durable mold that can withstand the casting process.

Unlike traditional sand casting methods that use clay as a binder, sodium silicate sand casting requires less moisture, which significantly decreases the likelihood of defects caused by moisture-related issues. This leads to enhanced dimensional accuracy and surface finish of the final cast products.

Advantages of Custom Sodium Silicate Sand Casting

1. Enhanced Precision One of the most significant advantages of sodium silicate sand casting is its ability to produce highly precise shapes and fine details. The rigidity of the mold allows for intricate designs and tight tolerances, making it ideal for complex components found in various industries, including automotive, aerospace, and machinery.

2. Efficient Production The chemical bonding nature of sodium silicate facilitates faster mold setting times, resulting in shorter lead times and increased production efficiency. Foundries can significantly reduce downtime, enabling them to meet tight deadlines and respond swiftly to customer demands.

custom sodium slicate sand casting

3. Sustainability Modern manufacturing practices emphasize sustainability, and sodium silicate sand casting aligns well with this trend. The use of sodium silicate as a binder minimizes the environmental impact associated with traditional molding materials. Moreover, the process generates less waste, and with proper recycling mechanisms, the sand can be reused, further enhancing its eco-friendly credentials.

4. Superior Surface Finish The smoothness of the molds created with sodium silicate also translates to a superior surface finish on the final cast products. This is particularly advantageous in industries where aesthetic appeal and surface texture are critical factors, such as in decorative items or precision fixtures.

5. Better Casting Quality The use of sodium silicate molds can decrease the incidence of common casting defects like sand inclusions and surface imperfections. The chemical properties of sodium silicate help create a mold that maintains its shape and integrity during pouring, thereby enhancing the overall quality of the cast metal.

Applications of Custom Sodium Silicate Sand Casting

The versatility of custom sodium silicate sand casting makes it suitable for a wide array of applications. Industries ranging from automotive parts manufacturing to HVAC components and even artistic sculptures benefit from its precision and quality. Furthermore, as manufacturers seek lighter materials and innovative designs, sodium silicate sand casting offers the flexibility needed to produce both lightweight and structurally sound components.

Conclusion

In summary, custom sodium silicate sand casting emerges as a transformative approach within the foundry industry, combining efficiency, precision, and sustainability in the casting process. As businesses continue to adapt and innovate in response to market demands, embracing this modern method could offer a competitive edge. Whether for high-volume production runs or intricate custom designs, sodium silicate sand casting stands poised to redefine manufacturing capabilities, ensuring that foundries can meet the challenges of today and tomorrow with confidence.

-

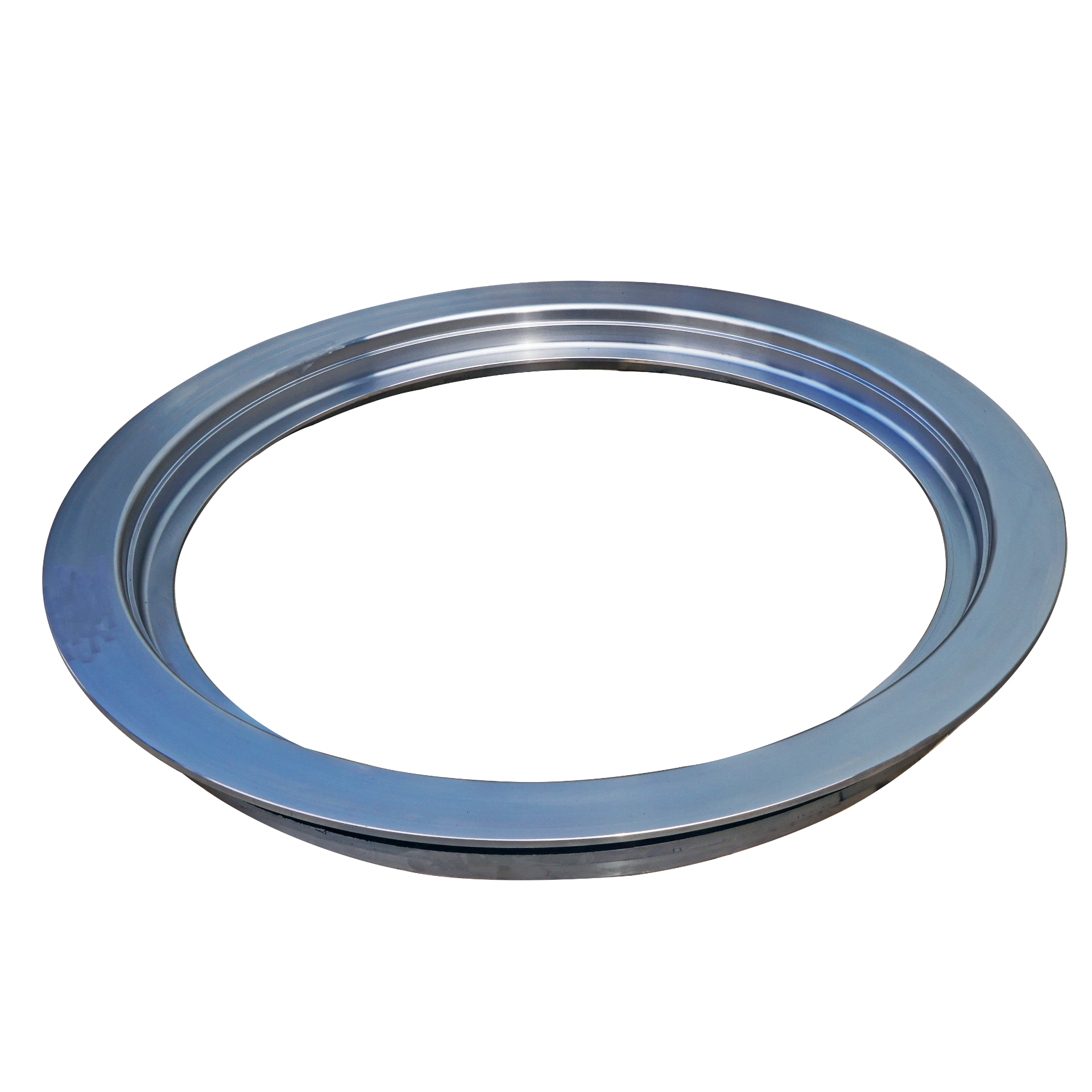

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025