- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 12, 2024 14:33 Back to list

dies casting

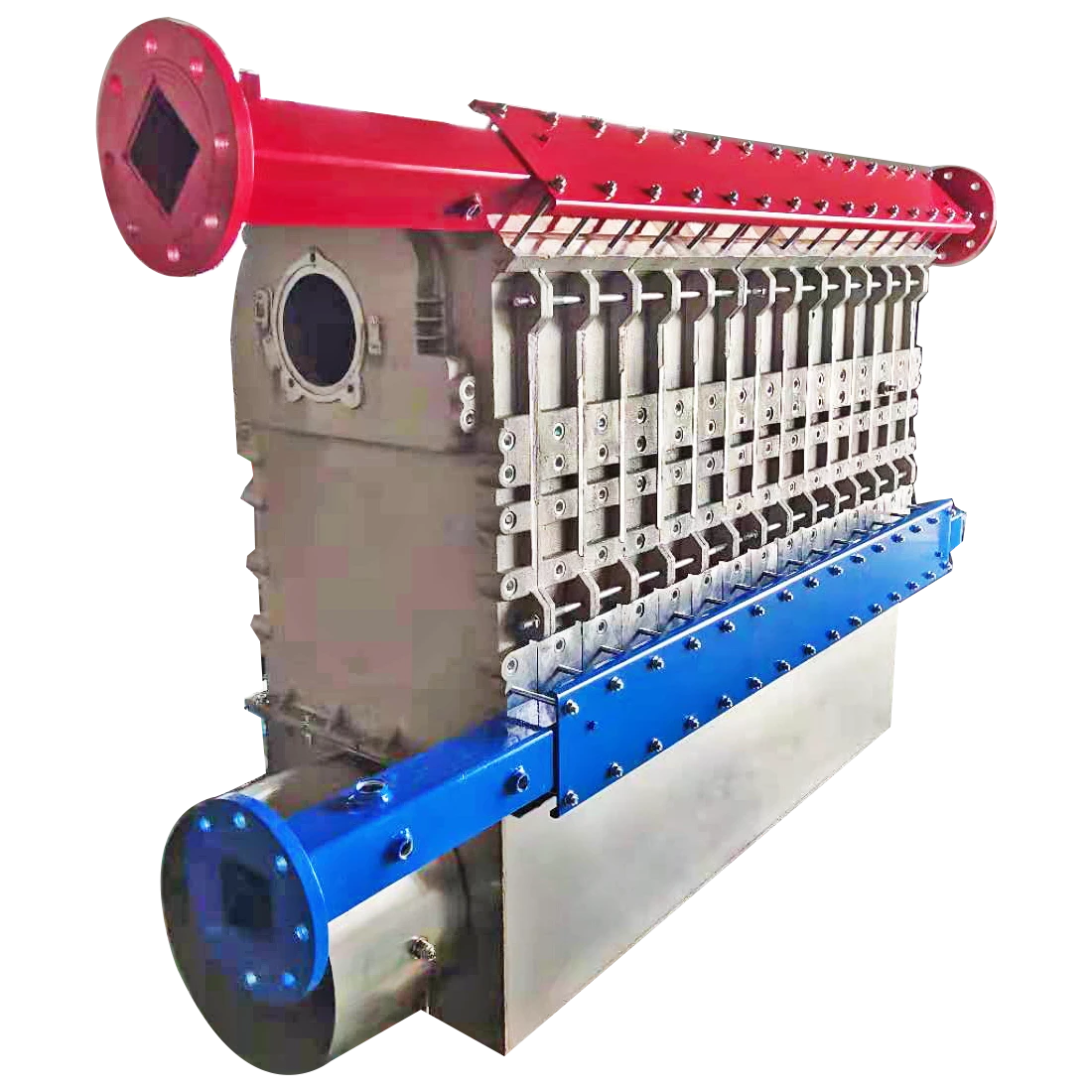

Die Casting An Overview of the Process and Its Applications

Die casting is a sophisticated manufacturing process that allows for the production of complex metal parts with high precision and intricate shapes. This process is widely used in various industries, including automotive, aerospace, electronics, and consumer goods, due to its capabilities to create durable and lightweight components. In this article, we will explore the die casting process, materials used, advantages, and its applications in different sectors.

The Die Casting Process

Die casting involves forcing molten metal into a mold cavity under high pressure. The two main types of die casting processes are hot chamber and cold chamber die casting. In hot chamber die casting, the pressure chamber is immersed in molten metal, making it suitable for metals with low melting points, such as zinc and magnesium. Cold chamber die casting, on the other hand, involves pouring molten metal into the chamber before it is injected into the mold. This process is typically used for higher melting point metals, such as aluminum and copper.

The die casting process begins with the preparation of the mold, which is usually made from steel and designed to withstand the high pressures involved. The mold is then heated to ensure the molten metal flows smoothly and reduces the risk of solidification before it fills the cavity. Once the molten metal is injected, it cools and solidifies into the desired shape. After the casting has cooled, the mold is opened, and the finished part is ejected.

Materials Used in Die Casting

The most commonly used materials in die casting include aluminum, zinc, magnesium, and copper alloys. Each material has its unique properties that make it suitable for different applications.

1. Aluminum Known for its lightweight and corrosion-resistant properties, aluminum die casting is widely used in the automotive and aerospace industries. Components such as engine blocks, transmission housings, and structural parts are often produced using this material.

2. Zinc Zinc die casting is favored for its excellent dimensional accuracy and smooth surface finish. It is used to create components for various industries, including electronics, hardware, and automotive applications.

dies casting

3. Magnesium Although it is less common, magnesium die casting is becoming increasingly popular due to its lightweight nature and high strength-to-weight ratio. It is often used in aerospace and automotive applications where weight reduction is critical.

4. Copper Alloys Copper is used in die casting for its excellent electrical conductivity and thermal resistance, making it ideal for components used in electrical and electronic devices.

Advantages of Die Casting

Die casting offers numerous advantages over other metalworking processes

- Precision and Accuracy Die casting produces parts with high dimensional accuracy and excellent surface finishes, reducing the need for extensive machining. - Efficiency The process allows for the production of large quantities of parts in a relatively short time, making it cost-effective for high-volume production.

- Material Utilization Minimal waste is generated during the die casting process, and recycled materials can also be used, contributing to sustainability.

Applications of Die Casting

Die casting is utilized across various industries. In the automotive sector, it is used to manufacture critical components such as engine parts, transmission cases, and gear housings. In the aerospace industry, precision-engineered parts made through die casting help reduce weight and improve fuel efficiency. Additionally, consumer electronics benefit from die-cast housings that provide both functionality and aesthetic appeal.

In conclusion, die casting is a vital manufacturing process that plays a crucial role in producing complex and durable components across multiple industries. Its ability to deliver high precision, efficiency, and material utilization makes it an attractive choice for manufacturers looking to enhance their productivity and product quality. As technology continues to advance, die casting is poised to further evolve, offering new possibilities in design and application.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025