- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 11, 2024 15:08 Back to list

Domestic Gas Boiler Manufacturers for Hot Water Systems

Domestic Hot Water Gas Boiler Factories An Overview

The need for efficient heating solutions in residences has driven the growth of domestic hot water gas boiler factories worldwide. These boilers are essential for providing hot water for various household activities, including bathing, cooking, and cleaning. In this article, we will explore the significance of these factories, the manufacturing process, and the impact of technological advancements in the industry.

The Importance of Domestic Hot Water Gas Boilers

Domestic hot water gas boilers play a critical role in modern living. With the increasing demand for energy-efficient heating systems, gas boilers have emerged as a reliable and economical choice for many households. They provide consistent and immediate access to hot water, which enhances comfort and convenience for families. Moreover, gas boilers are often preferred over electric counterparts due to their higher efficiency and lower operating costs.

Given their importance, it’s essential to ensure that these products are manufactured to high standards of quality and safety. This is where domestic hot water gas boiler factories come into play. These facilities are responsible for producing a variety of boiler models that cater to different household needs while adhering to strict regulatory guidelines.

Manufacturing Process in Boiler Factories

The manufacturing process of domestic hot water gas boilers involves several stages, starting from design and engineering to assembly and testing. Each stage is crucial to ensure the final product meets safety standards and customer requirements.

1. Design and Engineering The process begins with innovative design, where engineers utilize computer-aided design (CAD) software to create detailed specifications for the boiler. They must consider factors such as energy efficiency, heat output, and safety features.

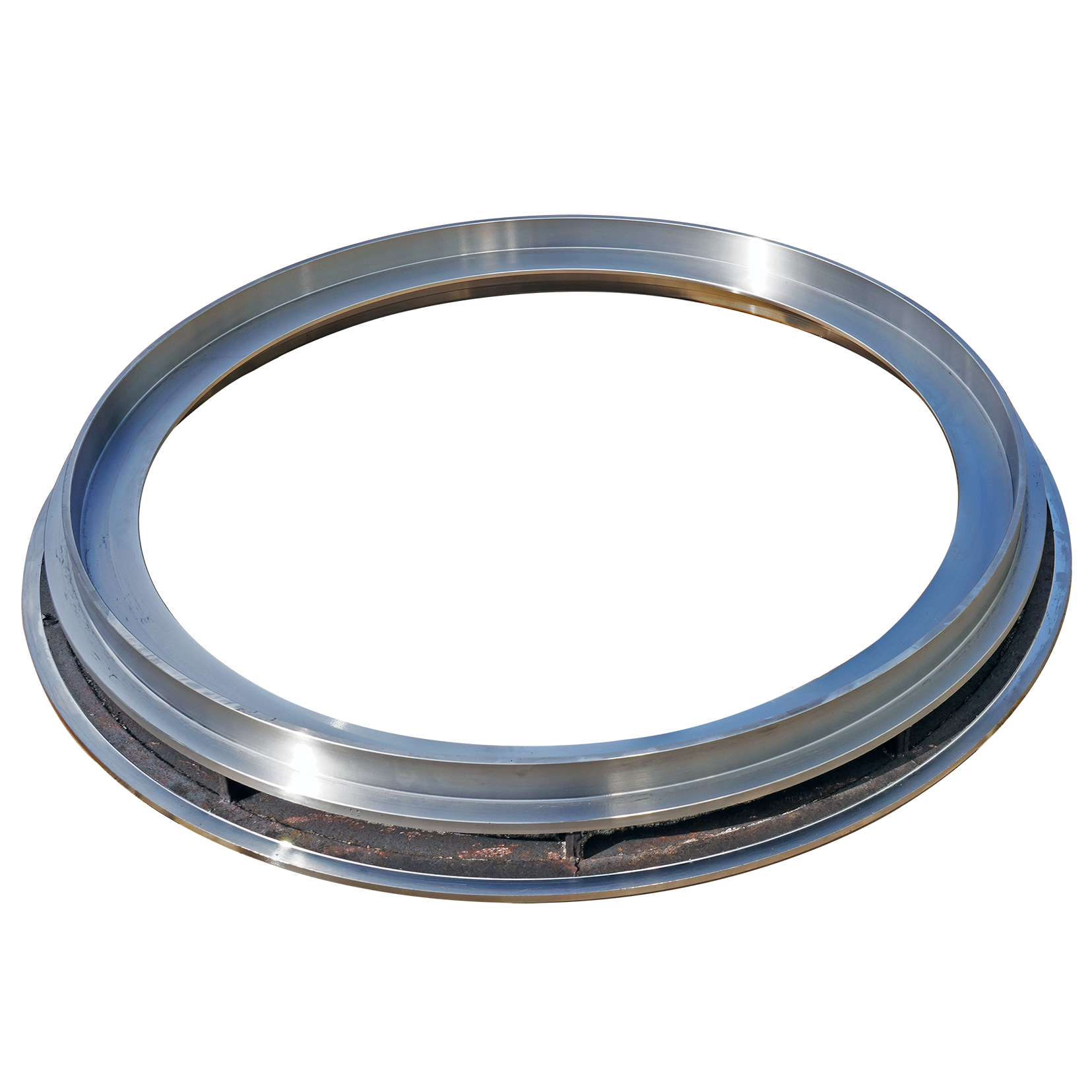

2. Material Selection Once the design is finalized, the next step is selecting the appropriate materials. High-quality metals and alloys are commonly used to withstand the high temperatures and pressures associated with gas boilers.

domestic hot water gas boiler factories

3. Fabrication and Assembly In this stage, the components of the boiler are fabricated and then assembled. Automated machinery plays a significant role in this process, ensuring precision and consistency in manufacturing.

4. Quality Control and Testing Before a boiler reaches the market, it undergoes rigorous testing to ensure it meets safety and performance standards. This involves pressure tests, efficiency evaluations, and safety compliance checks. Quality control is paramount, as faulty products can pose significant risks to users.

5. Distribution and Installation Once tested and approved, the boilers are packaged and distributed to various retailers or directly to consumers. Professional installation is essential for optimal performance and safety.

Technological Advancements in the Industry

In recent years, the domestic hot water gas boiler industry has witnessed significant technological advancements. Modern boilers are now equipped with smart technology that allows users to control their heating systems remotely via smartphones or smart home devices. This not only enhances convenience but also contributes to energy savings by allowing homeowners to manage their heating more efficiently.

Additionally, manufacturers are increasingly focusing on environmentally friendly practices. Many new models are designed with improved combustion efficiency and reduced emissions, aligning with global efforts to combat climate change.

Conclusion

Domestic hot water gas boiler factories are integral to providing energy-efficient heating solutions for households. With a focus on quality production, safety, and innovative technology, these factories play a vital role in enhancing the comfort of modern living. As the demand for sustainable and efficient energy solutions continues to grow, the industry will undoubtedly evolve, bringing forth even more advanced products to meet consumer needs.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025