- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 12, 2024 16:06 Back to list

dry cast reinfored concrete pipe mold pallet supplier

The Importance of Dry Cast Reinforced Concrete Pipe Mold Pallets in Construction

In the construction industry, the quality of concrete pipes is paramount to ensure durability and reliability in infrastructure projects. One critical component in producing high-quality concrete pipes is the mold used during the manufacturing process. Among the various types of molds available, dry cast reinforced concrete pipe mold pallets have emerged as an essential tool, offering numerous benefits to manufacturers and construction projects.

Understanding Dry Cast Concrete

Dry cast concrete refers to a type of concrete that has a low water-to-cement ratio, providing increased strength and durability. This method is particularly useful in producing reinforced pipes used in various applications, such as drainage, sewerage, and irrigation systems. The dry mix eliminates excess water, leading to a denser and stronger final product. However, to achieve the desired structural integrity, the right mold is crucial.

What are Concrete Pipe Mold Pallets?

Concrete pipe mold pallets are specialized casting surfaces designed to shape and support the molding of concrete pipes during the curing process. These pallets are typically made from high-quality materials that can withstand the pressures and weights associated with concrete casting. They facilitate the production of pipes in various diameters and lengths while ensuring uniformity and stability throughout the manufacturing process.

Advantages of Dry Cast Reinforced Concrete Pipe Mold Pallets

1. Enhanced Strength and Durability Dry cast reinforced concrete pipe mold pallets are specifically built to create strong molds that produce resilient pipes. The strength of these molds directly contributes to the durability of the concrete pipes, ensuring they can withstand heavy loads and environmental stresses.

2. Cost-Effectiveness Utilizing high-quality mold pallets can significantly reduce production costs over time. The durability of these pallets minimizes the frequency of replacements, lowering maintenance costs and enhancing the overall productivity of the manufacturing process.

dry cast reinfored concrete pipe mold pallet supplier

3. Improved Production Efficiency The design of dry cast reinforced concrete pipe mold pallets allows for faster casting processes. Their inherent strength means that manufacturers can produce pipes more quickly, improving turnaround times and increasing output without compromising quality.

4. Customization Capabilities Suppliers of these mold pallets often offer customized solutions tailored to specific project requirements. This adaptability ensures that manufacturers can produce a wide range of pipe sizes and shapes, catering to diverse construction needs.

5. Easier Handling and Transport Many mold pallet suppliers focus on designing lightweight and portable pallets, making them easier to transport and handle during the manufacturing process. This feature not only enhances efficiency but also minimizes the risk of workplace injuries.

Choosing the Right Supplier

When selecting a supplier for dry cast reinforced concrete pipe mold pallets, there are several factors to consider. It is essential to evaluate the supplier's reputation within the industry, as well as their experience and expertise in manufacturing concrete molds. Additionally, reviewing customer testimonials and case studies can provide valuable insights into the quality of their products.

Furthermore, an effective supplier should offer comprehensive customer support, guiding manufacturers through the selection of the right pallets based on their specific requirements. A reliable supplier will not only provide high-quality molds but will also be ready to assist with maintenance and troubleshooting to ensure consistent production quality.

Conclusion

Dry cast reinforced concrete pipe mold pallets play a critical role in the construction industry's ability to produce high-quality concrete pipes. By investing in durable and efficient molds, manufacturers can enhance their production processes, reduce costs, and ultimately contribute to the creation of robust infrastructure. As the demand for quality construction materials continues to grow, selecting the right mold pallet supplier becomes essential in achieving success in manufacturing and construction projects. The future of infrastructure development relies not only on innovative designs and materials but also on the methods and equipment used in their production.

-

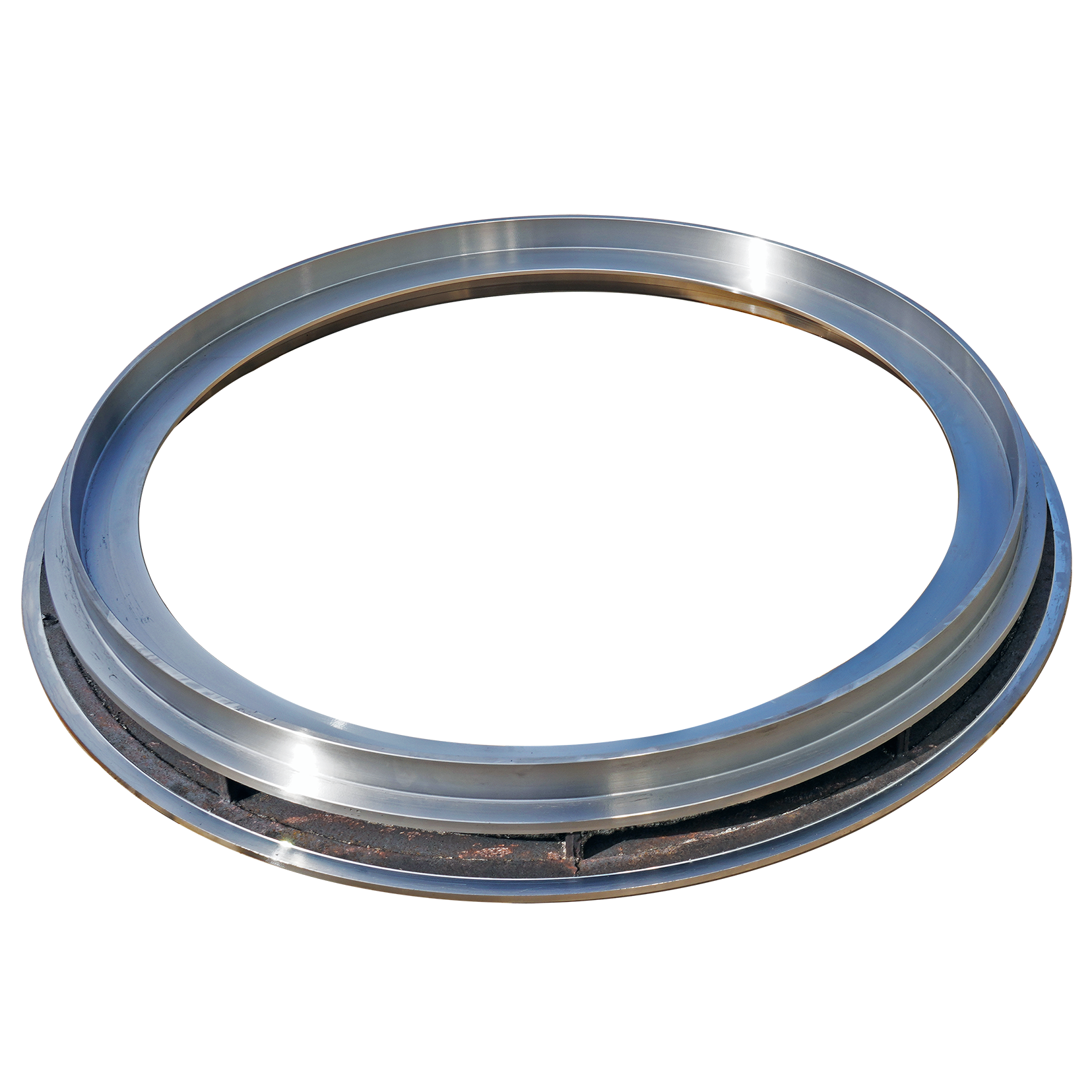

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025