- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 25, 2025 01:01 Back to list

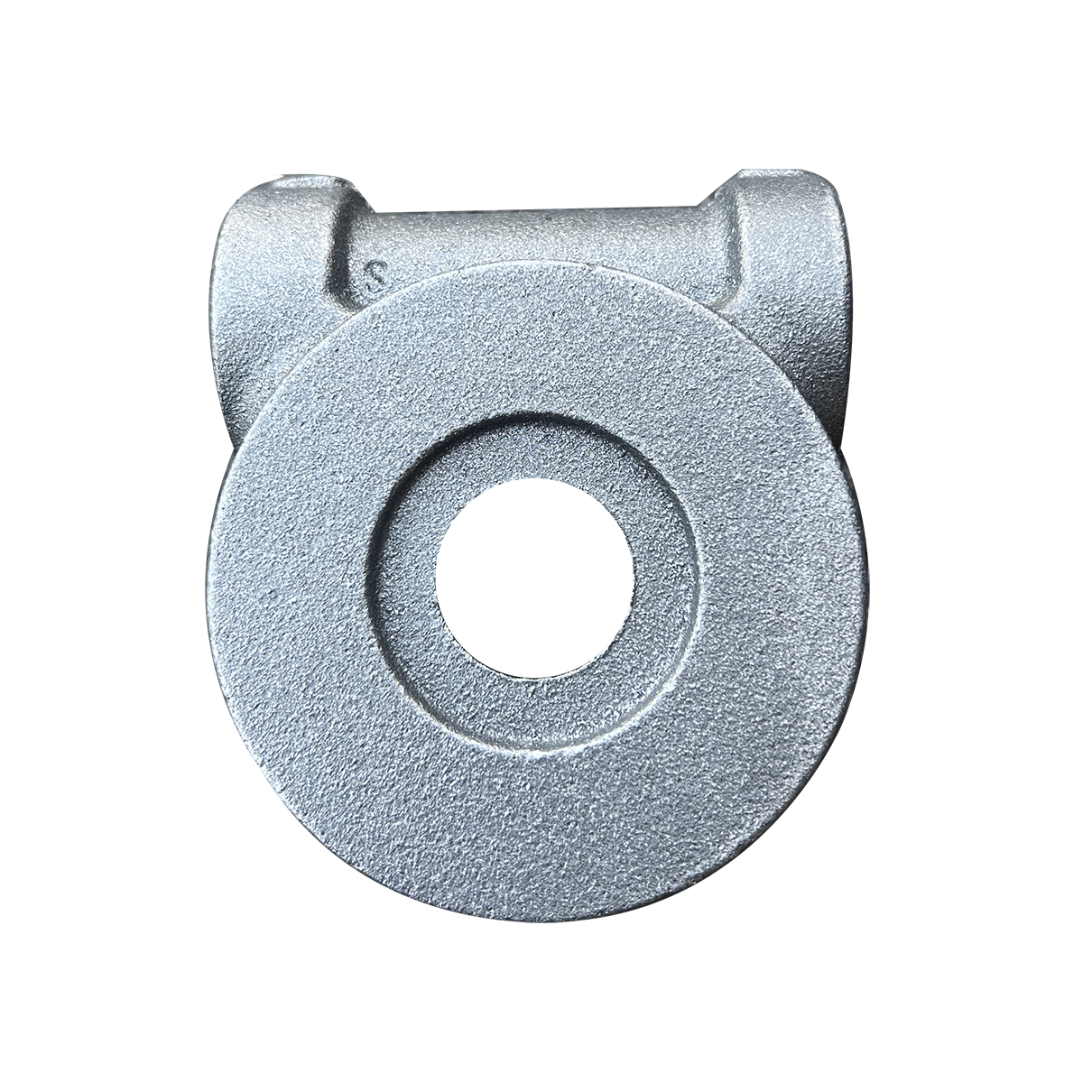

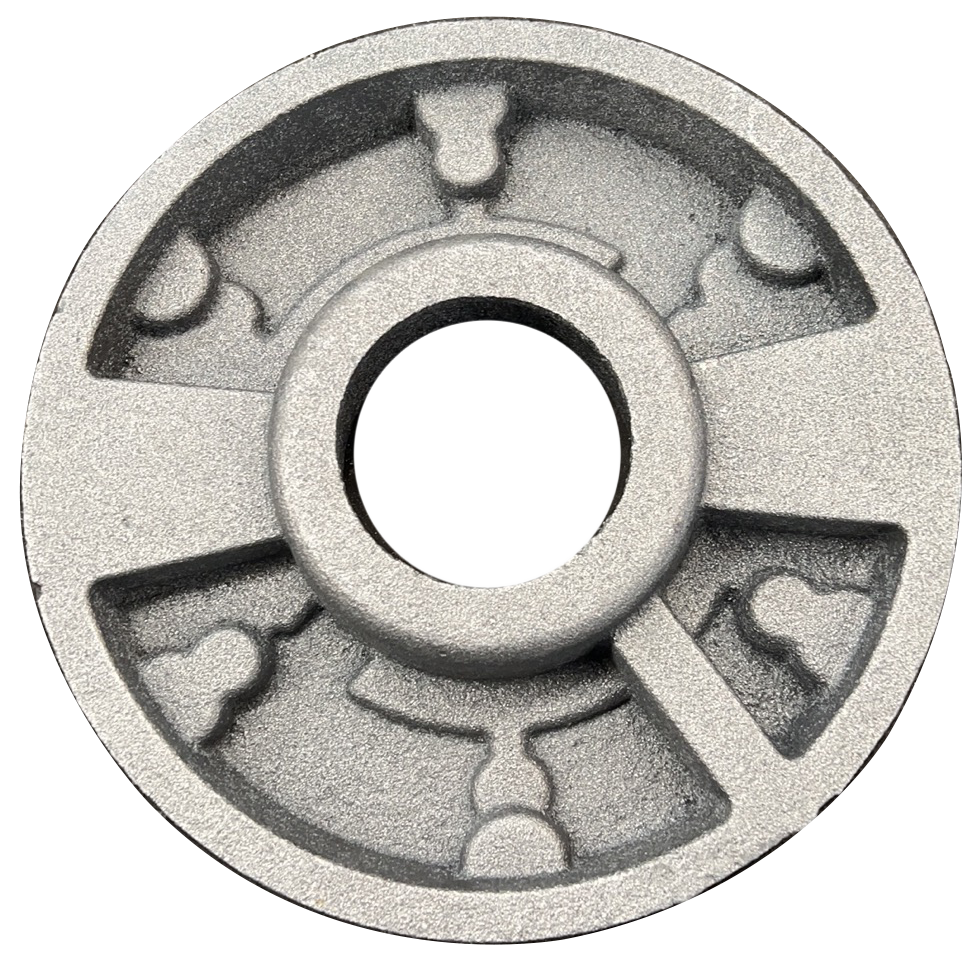

Ductile Iron Supplier Service from China Source Factory | Powerful Seller

In this guide, we analyze the evolving industry trends, explore technology and material parameters of ductile iron casting, compare suppliers and products, and provide answers to common technical questions. Whether you are an engineer, buyer, or supply chain manager, this in-depth resource ensures that your decision for Ductile Iron Supplier Service is informed by expertise, authoritativeness, and trustworthiness.

Website: https://www.casiting.com

Phone: 0086-311-67596450

Email: hjr1024@aliyun.com

Mobile: 008613832327186

Address: RM315, Baihui Building, No.57 Sizhong Road, Qiaoxi District, Shijiazhuang City, Hebei, China

China Original Suppliers have become international leaders by virtue of advanced production technologies—including fully automatic vertical parting and horizontal parting DISA lines—and dependable supply capabilities. As a Powerful Seller and Source Factory, Shijiazhuang Casiting Trading Co., Ltd. exemplifies this trend. With high-grade materials (ranging from QT400-18 to QT900-2), the company’s Ductile Iron Supplier Service delivers reliability, performance, and tailored OEM/ODM solutions for diverse applications worldwide.

- Materials: Ductile Cast Iron (QT400-18 / QT450-10 / QT500-7 / QT600-3 / QT700-2 / QT800-2 / QT900-2)

- Casting Processes: Sand Casting, Lost Foam Casting

- Equipment: Fully automatic vertical & horizontal parting DISA casting lines

- Product URL: Ductile Iron Supplier Service

| Parameter | Value (Standard Ranges) | Application Significance |

|---|---|---|

| Grade | QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2, QT900-2 | Classifies mechanical performance; determines toughness and strength |

| Tensile Strength (MPa) | 400 – 900 | High strength core for load-bearing applications |

| Yield Strength (MPa) | 250 – 620 | Resistance to deformation under stress |

| Elongation (%) | 2 – 18 | Indicates ductility—key for shock absorption |

| Hardness (HBW) | 130 – 320 | Wear-resistance for machinery, valves, heavy industry |

| Production Method | Sand casting, Lost foam casting | Refined shapes; cost-efficient mass production |

| Main Product Forms | Pipes, Fittings, Bushings, Housings, Manhole Covers | Widespread usage, especially municipal/construction |

Increasing emphasis on eco-friendly practices and digitalized foundry operations assures buyers of lower carbon footprints and robust sustainability credentials when they choose reputable China Original Supplier solutions.

- Municipal Pipeline & Waterworks: Ductile iron pipes and manhole covers provide longevity, strength, and anti-corrosive performance (ref: International Journal of Cast Metals Research).

- Automotive Industry: Parts such as axle housings, hubs, and crankshafts maximize fatigue resistance and geometry flexibility.

- Machinery & Heavy Industry: Gears, pulleys, and machine bases—where vibration dampening is vital.

- Energy Engineering: Used in renewable and conventional energy equipment due to excellent thermal properties.

- Construction & Infrastructure: Load-bearing components, architectural fittings, and high-performance supports.

- Vertical Integration: As a Source Factory, we control every link from raw material selection to automated casting and finishing.

- Global Export Leadership: Over 25+ destinations including Europe and the Americas, earning Powerful Seller trust.

- Certification & Quality: ISO9001, ISO14001, and OHSAS18001 authenticated, plus rigorous in-house material requirement verification.

- Technological Prowess: Employing cutting-edge horizontal/vertical DISA production, we achieve high repeatability and custom R&D flexibility.

- Fast Response & Customization: Rapid prototyping and OEM/ODM services tailored to specific application standards.

- Complete Traceability: All products feature code tracking for quality assurance.

Q1: What ductile iron grades does Shijiazhuang Casiting provide?

A: We provide a wide range: QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2, QT900-2, meeting ISO and ASTM standards, to fit every engineering and industrial need.

Q2: What production methods are used for your Ductile Iron Supplier Service?

A: We utilize sand casting for robust, large-volume components and lost foam casting for intricate, precision-driven shapes, both under intelligent DISA line automation.

Q3: What are the prevalent standards for ductile iron parts export?

A: Products comply with ISO 1083, EN1563, ASTM A536, GB/T1348; upon request, we meet specific region/industry requirements.

Q4: How is product quality controlled?

A: Full-process quality monitoring: raw material analysis, spectral testing, ultrasonic/impact/hardness checks, 3D measurement, and internal traceability codes.

Q5: What range of dimensions/specifications do you offer?

A: Customizable: from DN50 to DN2600 mm for pipes, with thickness tolerance of ±1.5mm or better, and varied geometries for mechanical parts.

Q6: What installation/documents are included?

A: Each shipment includes technical data sheets, installation guidelines meeting industry standards, inspection certificates, and ISO documentation.

Q7: What is the minimum order and lead time for the Ductile Iron Supplier Service?

A: MOQ: 1 ton or as negotiated.

Lead time: Typically 2–5 weeks, depending on product form, quantity, and custom requirements.

According to leading analysts (Foundry-Planet), key regions such as Europe, Asia Pacific, and North America show robust import demand, especially for expertly manufactured fittings, pipes, and OEM mechanical castings.

Supply chain partners increasingly value supplier scale, product traceability, and flexible customization—all strengths exemplified by Shijiazhuang Casiting’s Ductile Iron Supplier Service platform and network.

Explore more and request your solution at Ductile Iron Supplier Service

[1] International Journal of Cast Metals Research, Springer

[2] Foundry-Planet Industry Forum

[3] China Mechanical Engineering Forum: https://www.c-c.com/forum-14-1.html

[4] Castings Technology International: Industry Publications

[5] "Ductile Iron Handbook", American Foundry Society (AFS Publications)

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025