- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 16, 2024 23:29 Back to list

ductile castings

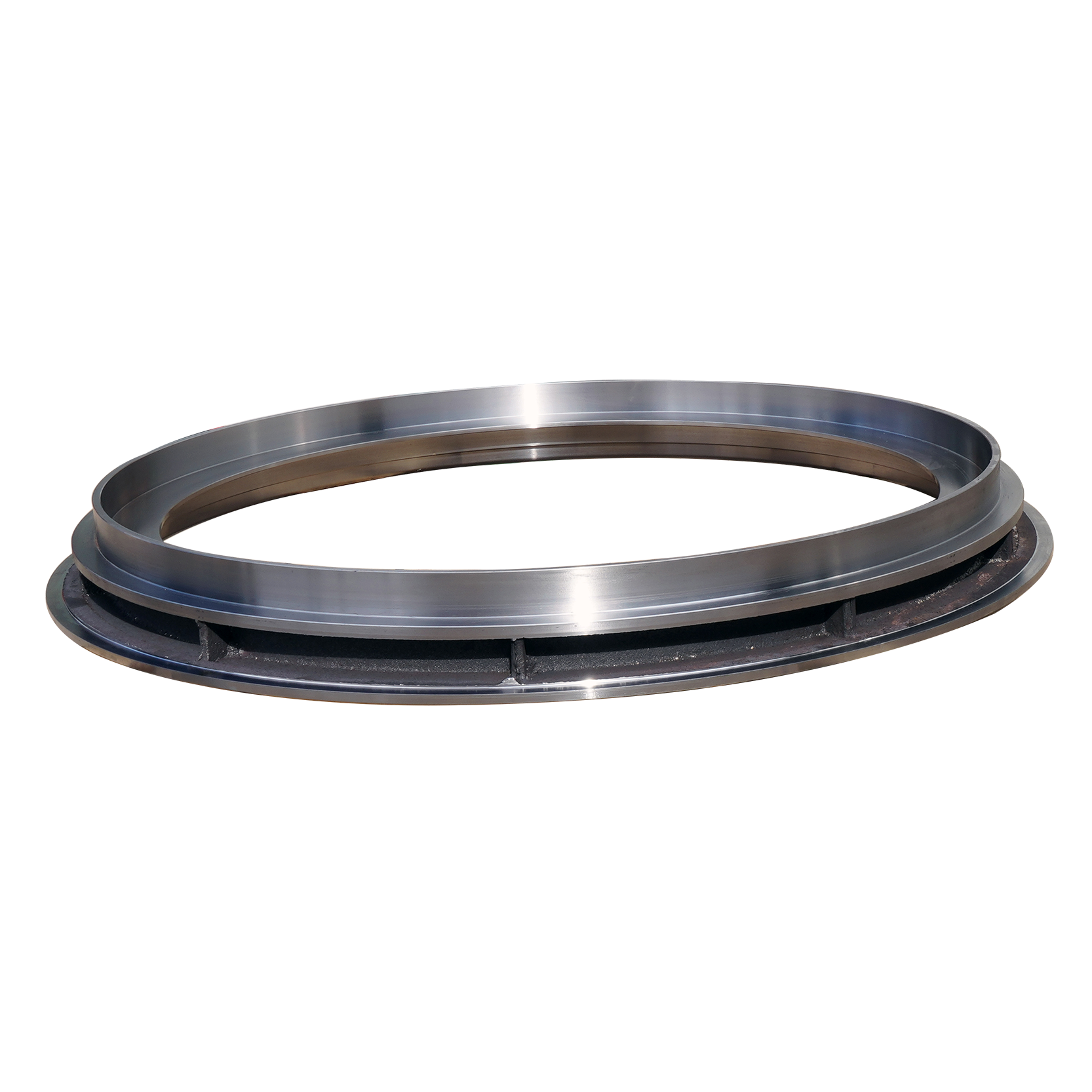

Ductile Castings A Comprehensive Overview

Ductile castings, also known as ductile iron castings or spheroidal graphite castings, are a remarkable advancement in the field of metallurgy. Introduced in the 1940s, ductile iron offers mechanical properties similar to those of steel while retaining the excellent casting characteristics of iron. The unique features of ductile castings make them a preferred choice in various industrial applications.

One of the defining characteristics of ductile castings is their enhanced ductility, which allows them to deform under stress without breaking. This is primarily due to the presence of spheroidal graphite structures within the iron matrix. Unlike traditional cast iron, where graphite appears in the form of flakes, ductile iron's spherical graphite enhances the overall toughness and strength of the material. As a result, ductile castings can withstand higher loads and exhibit better impact resistance.

The production of ductile castings involves a special process where molten iron is treated with elements such as magnesium. This treatment alters the solidification pattern of graphite in the cast iron, leading to the formation of the desirable spheroidal shape. The careful control of alloying elements and casting conditions is vital, as it directly impacts the final properties of the casting.

ductile castings

Ductile castings have found widespread use in various industries due to their exceptional performance. For instance, in the automotive sector, they are commonly utilized in the manufacturing of crankshafts, axle housings, and various structural components. Their ability to absorb shocks and vibrations makes them ideal for these demanding applications. Furthermore, ductile castings are increasingly being employed in the production of pipes and fittings for water and wastewater systems, where their corrosion resistance and tensile strength are essential.

Another advantage of ductile castings is their ability to be machined easily. This characteristic is especially important in manufacturing where precision is required. Ductile iron can be machined to close tolerances, allowing for high-quality finishes on components. This machining capability, combined with the material's strength, makes ductile castings a favorable option in regions where both durability and product integrity are critical.

The environmental footprint of ductile castings is also worth noting. Compared to other materials, the production process of ductile iron often generates less waste and can utilize recycled materials, making it a more sustainable choice. As industries worldwide shift towards greener practices, the demand for ductile castings may continue to rise, especially in sectors that prioritize sustainability alongside performance.

In conclusion, ductile castings represent a significant technological advancement in material science. Their unique combination of strength, ductility, and machinability makes them suitable for a wide range of applications, from automotive components to infrastructure. As industries evolve and the demand for high-performance materials increases, the versatility and reliability of ductile castings will ensure their place at the forefront of modern manufacturing. Whether in traditional industries or new technological arenas, ductile castings are poised to play a critical role in shaping the future of production and design.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025