- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 15, 2024 02:56 Back to list

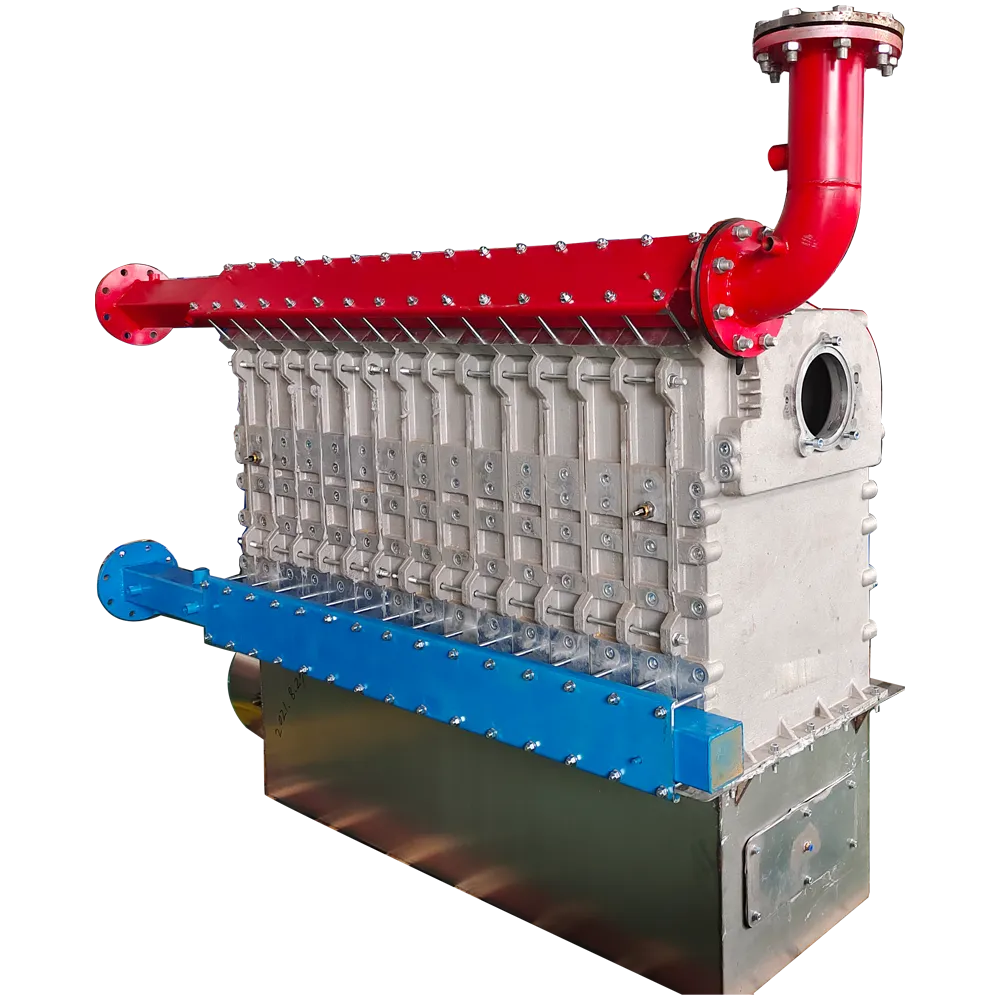

ductile iron casting factory

The Process and Importance of Ductile Iron Casting in Modern Manufacturing

Ductile iron casting, renowned for its superior mechanical properties and versatility, plays an essential role in various industries, including automotive, aerospace, and heavy machinery. With its unique combination of strength, ductility, and resistance to wear and fatigue, ductile iron has become a popular choice for manufacturers worldwide. This article explores the characteristics of ductile iron, the casting process, the benefits of working with ductile iron casting factories, and its various applications.

What is Ductile Iron?

Ductile iron, also known as spheroidal graphite iron or nodular cast iron, is an iron-carbon alloy that exhibits exceptional ductility and tensile strength. The key to its remarkable properties lies in the microstructure, where graphite is present in the form of nodules. This unique structure results from the addition of specific alloying elements, such as magnesium, during the melting process. Compared to traditional gray iron, which has flake graphite, ductile iron is more resistant to impact and stress, making it suitable for demanding applications.

The Ductile Iron Casting Process

Ductile iron casting involves several well-defined stages to produce high-quality components. The process typically begins with the melting of raw iron in a furnace, where the addition of carbon and alloying elements occurs. The molten iron is then poured into molds, which can be made from sand, metal, or other materials depending on the desired outcome and complexity of the parts.

1. Melting and Alloying The first step is to heat the iron to its melting point, where it becomes a liquid. Alloying agents like magnesium and cerium are added to promote the formation of spheroidal graphite.

2. Pouring Once the molten iron is prepared, it is poured into pre-made molds. These molds can vary in complexity, allowing for the production of intricately designed components.

3. Cooling and Solidification After pouring, the molten iron cools and solidifies. Proper cooling techniques are essential to achieving the desired mechanical properties and preventing defects.

4. Finishing After the casting has cooled, it is removed from the mold. Additional finishing processes, such as machining, grinding, or surface treatment, may be applied to achieve the required specifications and surface quality.

Advantages of Ductile Iron Casting Factories

ductile iron casting factory

Working with ductile iron casting factories presents numerous advantages for manufacturers

.- Customizability Ductile iron casting can be tailored to meet specific engineering requirements, allowing for the production of complex and customized components. Factories often collaborate closely with clients to ensure that their unique needs are met.

- Cost-effectiveness The ability to produce intricate designs without the need for extensive tooling can significantly reduce manufacturing costs. Moreover, ductile iron's longevity and durability mean that end products often require less frequent replacement or repair.

- Scalability Ductile iron casting facilities can scale production to accommodate both small and large orders, providing flexibility for businesses of all sizes.

- Quality Control Reputable ductile iron casting factories implement rigorous quality control measures to ensure that every product meets industry standards. This includes testing for mechanical properties, dimensional accuracy, and surface finish.

Applications of Ductile Iron Castings

Ductile iron castings are utilized across a broad spectrum of industries

- Automotive Used for components such as crankshafts, axle housings, and suspension parts, which require high strength and resistance to wear.

- Construction and Infrastructure Ductile iron is widely used in the manufacturing of pipes, valves, and fittings due to its excellent corrosion resistance and durability.

- Heavy Machinery Components like gears, frames, and housings are often made from ductile iron due to its ability to withstand high loads and impacts.

In conclusion, ductile iron casting has become a cornerstone of modern manufacturing, offering significant advantages in terms of strength, versatility, and cost-effectiveness. As industries continue to evolve and demand innovative solutions, the importance of ductile iron casting factories will undoubtedly grow, making them critical players in the global manufacturing landscape.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025