- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 09, 2024 15:17 Back to list

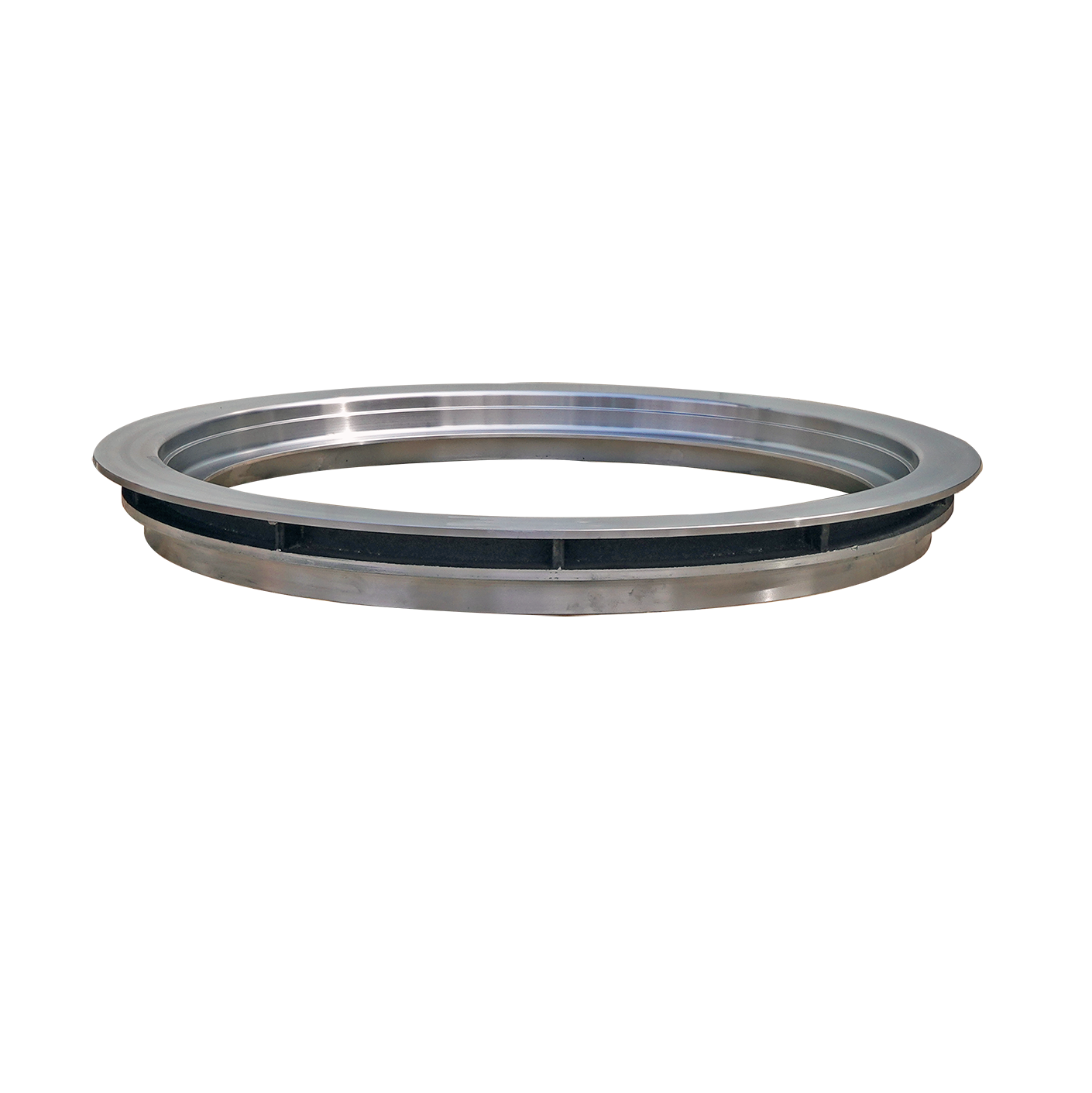

ductile iron pipe mould bottom ring factory

The Importance of Ductile Iron Pipe Mould Bottom Rings A Comprehensive Overview

Ductile iron pipe mould bottom rings play a crucial role in the manufacturing of ductile iron pipes, which are extensively used in various industries including water supply, wastewater management, and industrial applications. With their exceptional strength, ductility, and corrosion resistance, ductile iron pipes have become the material of choice for engineers and designers worldwide. In this article, we will explore the significance of mould bottom rings in the production process, their manufacturing methods, and the benefits they offer to the overall performance of ductile iron pipes.

Understanding Ductile Iron and Its Applications

Ductile iron is a type of cast iron that exhibits enhanced ductility and toughness due to the presence of spherical graphite in its microstructure. This material is produced through a process known as ductilization, which involves the addition of alloying elements like magnesium. As a result, ductile iron pipes are capable of withstanding high pressures and aggressive environments, making them suitable for a variety of applications such as municipal water supply, sewage systems, and industrial piping.

The Role of Mould Bottom Rings

Mould bottom rings are integral components in the manufacturing of ductile iron pipes, particularly during the casting process. These rings are designed to provide a sturdy and stable base for the pipe mould, ensuring that the molten iron can be poured accurately and efficiently. The bottom rings help to maintain the proper alignment of the mould halves, preventing any misalignment that could lead to defects in the finished product.

The manufacturing of ductile iron pipes involves complex processes, including mould making, pouring, and solidification. The mould bottom rings are crucial because they bear the weight of the mould and the molten iron during these steps. A well-designed mould bottom ring contributes significantly to the overall quality and consistency of the pipe, reducing the risk of defects such as sagging, misalignment, or uneven wall thickness.

Manufacturing Mould Bottom Rings

ductile iron pipe mould bottom ring factory

The production of mould bottom rings typically involves the use of high-quality materials and advanced manufacturing techniques. The rings are often made from high-strength steel or cast iron, which provides the durability needed to withstand the stresses associated with the casting process. Precision engineering ensures that the dimensions of the mould bottom rings adhere closely to industry standards, thereby guaranteeing optimal performance.

Manufacturers also employ various techniques, including machining, surface treatment, and heat treatment, to enhance the properties of mould bottom rings. These processes improve wear resistance, increase strength, and extend the lifespan of the mould components, ultimately leading to more efficient production cycles and lower costs for manufacturers.

Benefits of High-Quality Mould Bottom Rings

Investing in high-quality mould bottom rings brings several benefits to ductile iron pipe manufacturers. Firstly, they ensure a higher rate of successful casts, reducing scrap and minimizing production costs. Secondly, consistent quality in the mould bottom rings translates to fewer defects in the final products, which enhances the reputation of the manufacturer and increases customer satisfaction.

Moreover, better mould bottom rings lead to improved cycle times, as they can withstand the rigors of repeated casting processes without significant wear and tear. This results in increased productivity and higher output levels for manufacturers. Finally, using durable and reliable mould components supports sustainability efforts by reducing waste and energy consumption during manufacturing.

Conclusion

In conclusion, mould bottom rings are an indispensable part of the ductile iron pipe manufacturing process. Their role in ensuring accurate and efficient casting cannot be overstated. As the demand for ductile iron pipes continues to grow, the importance of high-quality mould bottom rings will only become more pronounced. Investing in advanced manufacturing techniques and materials for these components will pave the way for improved product quality, enhanced operational efficiency, and greater satisfaction among customers in various sectors reliant on ductile iron piping solutions.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025