- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 07, 2024 13:17 Back to list

Energy Transfer Optimization in Finned Tube Heat Exchangers for Enhanced Efficiency

Enhancing Energy Transfer in Finned Tube Heat Exchangers

Heat exchangers play a crucial role in various industrial processes by transferring thermal energy between two or more fluids. Among the various designs, finned tube heat exchangers are particularly renowned for their efficiency in enhancing energy transfer. By incorporating fins into the tubing, these devices significantly increase the surface area available for heat transfer, leading to improved thermal performance. This article delves into the principles, applications, and benefits of finned tube heat exchangers, highlighting their importance in energy transfer processes.

Principles of Energy Transfer

Energy transfer in heat exchangers involves the conduction and convection of heat from one fluid to another. In finned tube heat exchangers, the basic principle hinges on the concept that increasing the surface area will enhance heat transfer rates. The fins, which can be attached to the outer surface of the tubes, promote additional heat transfer by augmenting the area in contact with the surrounding fluid.

The primary mechanisms of heat transfer include conduction (heat transfer through solid materials), convection (heat transfer through fluid movement), and radiation (heat transfer through electromagnetic waves). In finned tube designs, convection plays a dominant role, particularly in applications involving air or other gases, as the fins create turbulence in the fluid flow, which disrupts the boundary layer and enhances heat transfer efficiency.

Design Variations and Materials

Finned tube heat exchangers can be customized based on specific operational requirements, including the type of fluids involved, temperature ranges, and operational pressures. The design usually involves either longitudinal or transverse fins, with each configuration offering distinct advantages depending on the application.

Material selection for the fins and tubes is critical for optimizing energy transfer while ensuring durability and resistance to corrosion or fouling. Common materials include copper and aluminum for their excellent thermal conductivity, while stainless steel is favored in corrosive environments. Additionally, the thickness and spacing of the fins can be optimized to balance the trade-off between heat transfer efficiency and pressure drop within the system.

Applications

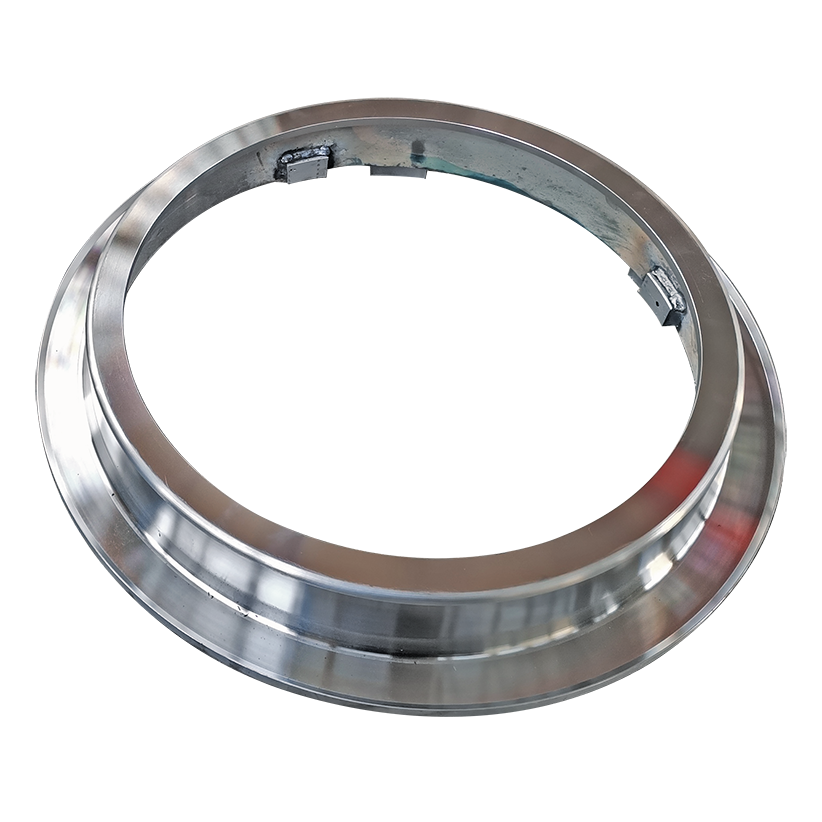

energy transfer finned tube

Finned tube heat exchangers are employed in a wide range of industries, including power generation, petrochemical, refrigeration, and HVAC systems. In power plants, these devices facilitate efficient heat recovery, ultimately enhancing overall system efficiency. In the petrochemical industry, they play a pivotal role in recovering heat from processes, reducing the energy footprint of operations.

In HVAC applications, finned tube heat exchangers contribute to energy-efficient climate control systems, allowing for effective heating and cooling of indoor spaces. Additionally, they are commonly used in applications involving condensation or evaporation, such as in cooling towers and condensers.

Benefits of Finned Tube Heat Exchangers

One of the primary benefits of finned tube heat exchangers is their capability to maximize heat transfer within a compact design. The increased surface area offered by the fins results in enhanced efficiency, allowing systems to operate at lower temperatures without sacrificing performance. This, in turn, leads to reduced energy consumption and lower operational costs.

Moreover, the versatility of finned tube designs means they can be tailored to meet specific requirements, making them suitable for diverse applications ranging from residential heating systems to large-scale industrial environments. Their ability to operate effectively in varying heat transfer conditions also contributes to their popularity.

Another advantage is the relatively easy maintenance and cleaning of finned tube heat exchangers. While fouling can occur over time, the design allows for straightforward access, which is essential for ensuring long-term operational efficiency and reliability.

Conclusion

In conclusion, finned tube heat exchangers represent a vital component in modern thermal management systems. By significantly enhancing energy transfer efficiency through innovative design, they play a key role in industries seeking to optimize thermal processes and reduce energy consumption. As industries continue to prioritize sustainability and efficiency, the importance of effectively designed finned tube heat exchangers will only grow, contributing to technological advancements and improved energy utilization across various sectors. As we move towards a more energy-conscious future, the innovations in finned tube technology will undoubtedly remain at the forefront of efficient energy transfer solutions.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025