- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 13, 2024 11:02 Back to list

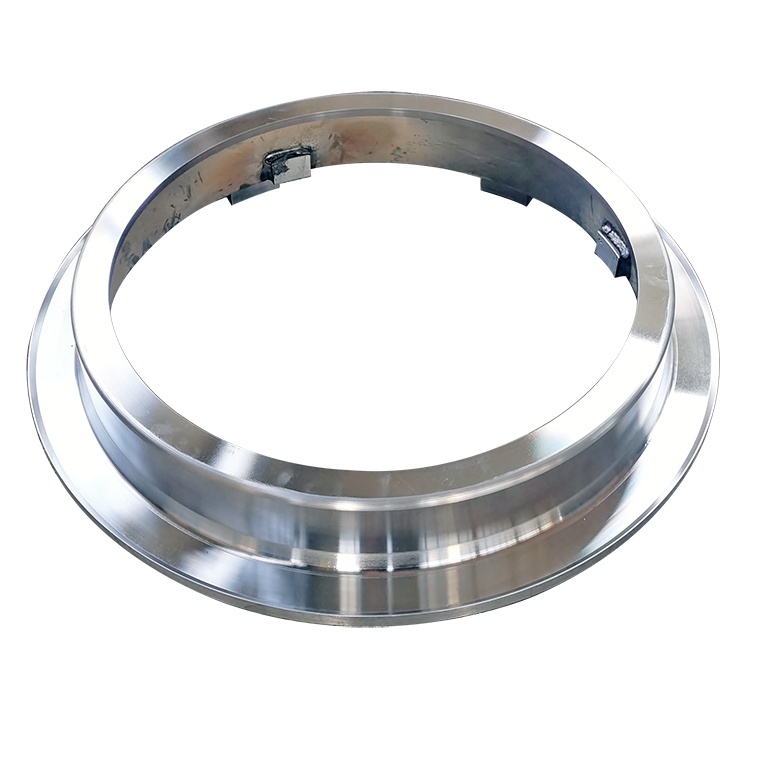

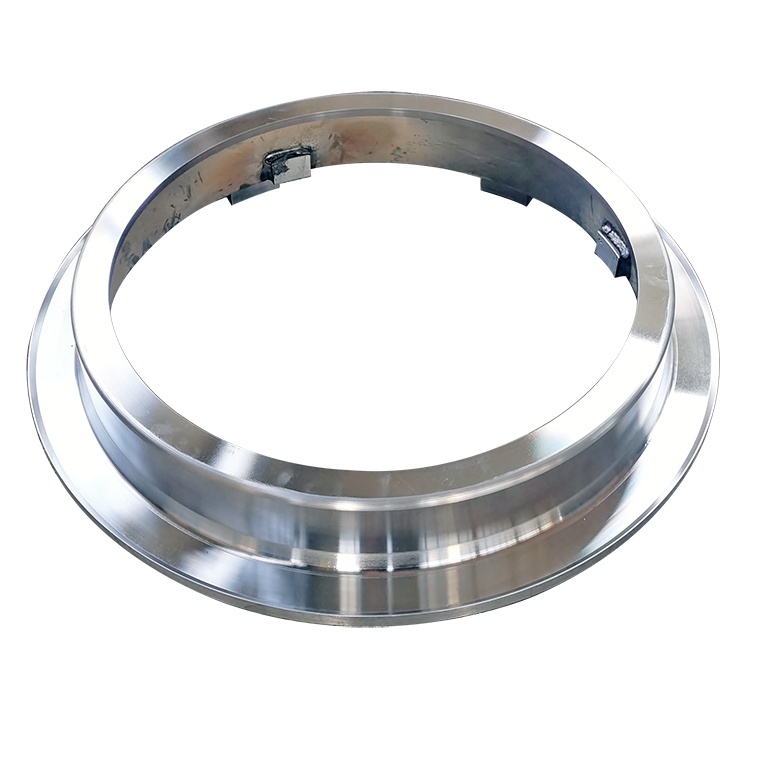

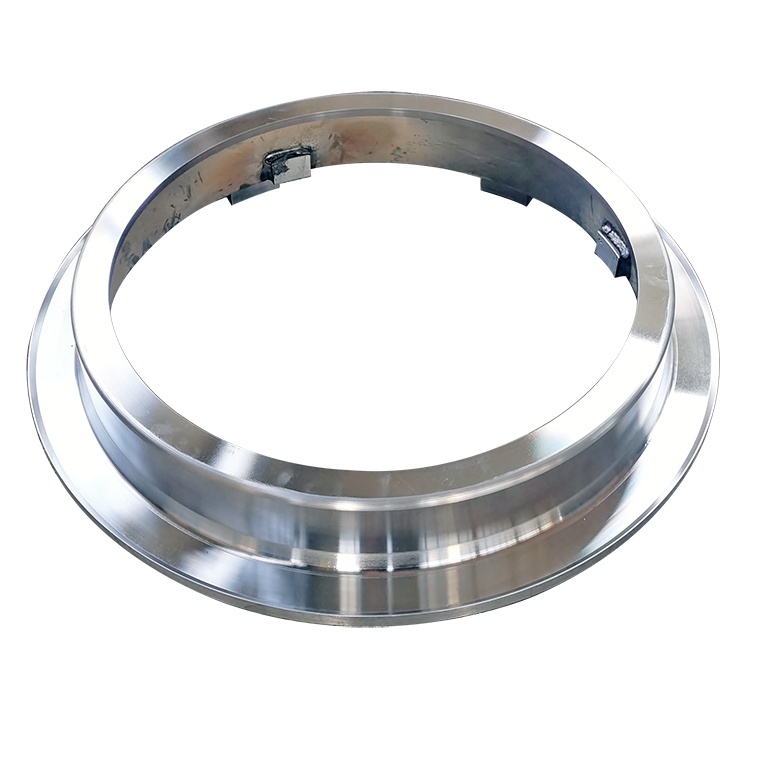

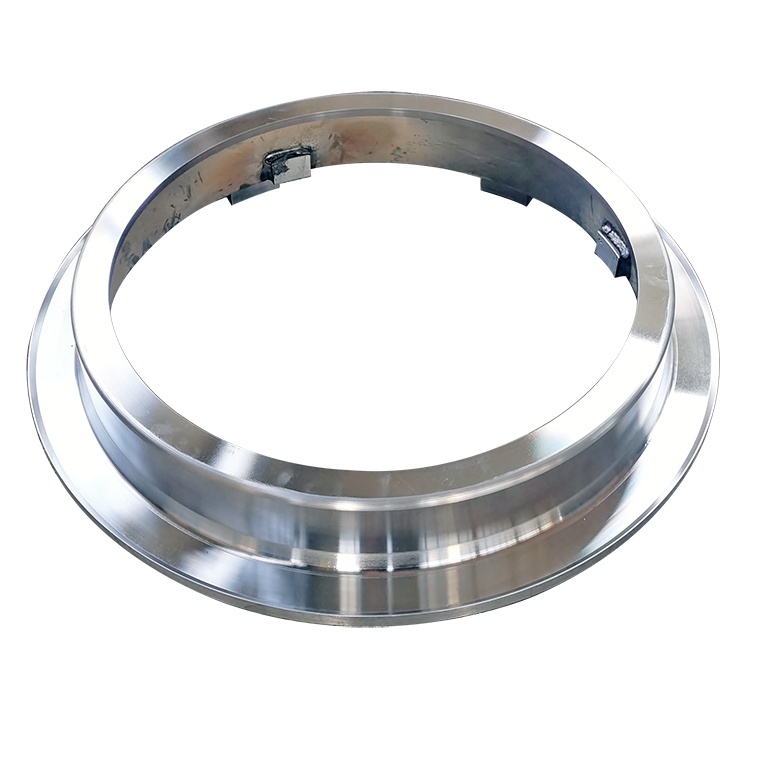

Expert in manufacturing casting products

The Pivotal Role of Casting Products Manufacturers in Modern Industry

In the vast expanse of industrial manufacturing, casting products manufacturers hold a crucial position. They are the backbone of sectors ranging from automotive to aerospace, from construction to machinery, and from medical devices to consumer goods. Their work, often unseen but always significant, shapes the world we live in.

Casting is a process that involves pouring molten material, typically metal or glass, into a mold to create a specific shape. It's an ancient technique that has evolved over centuries, becoming more precise and efficient with advancements in technology. Today, casting products manufacturers utilize cutting-edge techniques like sand casting, die casting, investment casting, and permanent mold casting to produce components with unparalleled accuracy and consistency.

These manufacturers specialize in creating a wide array of products, from intricate engine parts for automobiles to the sturdy frames of construction equipment. In the automotive industry, for instance, casting products are vital for engine blocks, transmission cases, and suspension components. In aerospace, they produce lightweight yet robust parts for aircraft engines and structural components.

The precision and durability of casting products make them indispensable in the manufacturing of high-stress and safety-critical components. For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties

For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties casting products manufacturer.

Casting products manufacturers also play a pivotal role in sustainability. By recycling scrap metals and using energy-efficient processes, they contribute to a circular economy. Moreover, the ability to create complex geometries with minimal waste makes casting an environmentally friendly production method.

However, the journey from raw materials to finished products is not without challenges. Manufacturers must navigate strict regulations, manage supply chain complexities, and continually innovate to stay ahead in a competitive landscape. They invest heavily in research and development to improve casting processes, reduce defects, and enhance product performance.

In essence, casting products manufacturers are not just creators of physical objects; they are catalysts of progress, driving innovation and shaping industries. Their work is a testament to human ingenuity and the relentless pursuit of perfection in manufacturing. As technology continues to evolve, the role of these manufacturers will only become more critical, ensuring the continued advancement of various sectors and our daily lives.

casting products manufacturer.

Casting products manufacturers also play a pivotal role in sustainability. By recycling scrap metals and using energy-efficient processes, they contribute to a circular economy. Moreover, the ability to create complex geometries with minimal waste makes casting an environmentally friendly production method.

However, the journey from raw materials to finished products is not without challenges. Manufacturers must navigate strict regulations, manage supply chain complexities, and continually innovate to stay ahead in a competitive landscape. They invest heavily in research and development to improve casting processes, reduce defects, and enhance product performance.

In essence, casting products manufacturers are not just creators of physical objects; they are catalysts of progress, driving innovation and shaping industries. Their work is a testament to human ingenuity and the relentless pursuit of perfection in manufacturing. As technology continues to evolve, the role of these manufacturers will only become more critical, ensuring the continued advancement of various sectors and our daily lives.

For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties

For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties For example, in the medical field, casting is used to create surgical instruments and orthopedic implants, demanding stringent quality control and exceptional material properties casting products manufacturer.

Casting products manufacturers also play a pivotal role in sustainability. By recycling scrap metals and using energy-efficient processes, they contribute to a circular economy. Moreover, the ability to create complex geometries with minimal waste makes casting an environmentally friendly production method.

However, the journey from raw materials to finished products is not without challenges. Manufacturers must navigate strict regulations, manage supply chain complexities, and continually innovate to stay ahead in a competitive landscape. They invest heavily in research and development to improve casting processes, reduce defects, and enhance product performance.

In essence, casting products manufacturers are not just creators of physical objects; they are catalysts of progress, driving innovation and shaping industries. Their work is a testament to human ingenuity and the relentless pursuit of perfection in manufacturing. As technology continues to evolve, the role of these manufacturers will only become more critical, ensuring the continued advancement of various sectors and our daily lives.

casting products manufacturer.

Casting products manufacturers also play a pivotal role in sustainability. By recycling scrap metals and using energy-efficient processes, they contribute to a circular economy. Moreover, the ability to create complex geometries with minimal waste makes casting an environmentally friendly production method.

However, the journey from raw materials to finished products is not without challenges. Manufacturers must navigate strict regulations, manage supply chain complexities, and continually innovate to stay ahead in a competitive landscape. They invest heavily in research and development to improve casting processes, reduce defects, and enhance product performance.

In essence, casting products manufacturers are not just creators of physical objects; they are catalysts of progress, driving innovation and shaping industries. Their work is a testament to human ingenuity and the relentless pursuit of perfection in manufacturing. As technology continues to evolve, the role of these manufacturers will only become more critical, ensuring the continued advancement of various sectors and our daily lives. Share

Pervious:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025