- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 13, 2024 17:59 Back to list

Exploring the Benefits and Applications of Foundry Cast Iron in Modern Manufacturing Processes

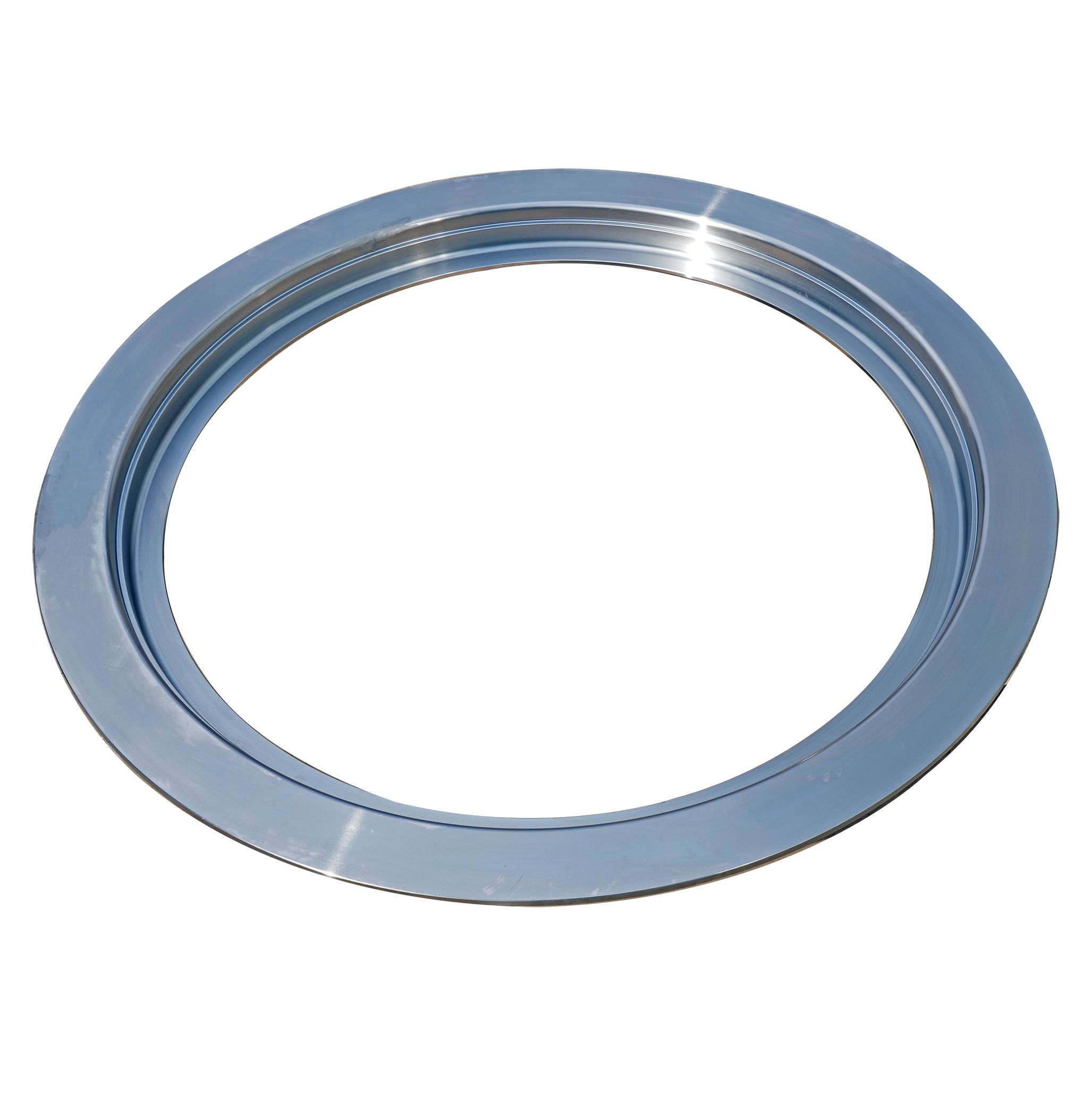

Foundry Cast Iron A Versatile Material for Modern Applications

Foundry cast iron is one of the most significant materials in the manufacturing and construction industries, recognized for its outstanding properties and versatility. Derived from molten iron, cast iron is poured into molds to achieve various shapes and forms, making it a staple in many applications, from cookware to engineering components.

One of the key characteristics that set foundry cast iron apart is its excellent casting ability

. This material can be easily shaped into complex geometries and intricate patterns, which makes it ideal for producing everything from pipes and machinery parts to decorative elements. The combination of high fluidity and minimal shrinkage upon cooling allows for precision in manufacturing, reducing the need for extensive machining processes.There are several types of cast iron, with gray cast iron being the most commonly used in foundries. This type is characterized by its graphite flakes, which give it a gray appearance when fractured. Gray cast iron possesses excellent machinability, and its ability to dampen vibrations makes it suitable for applications that require precision, such as engine blocks and industrial machinery. White cast iron, on the other hand, has a bright, white fracture surface due to the presence of cementite and is typically harder and more brittle. It can be used in applications where wear resistance is crucial, such as in grinding media and wear plates.

foundry cast iron

Cast iron also has a unique property of thermal conductivity, making it a preferred material for cookware, particularly frying pans and Dutch ovens. These items benefit from cast iron's ability to distribute heat evenly, ensuring consistent cooking results. Moreover, cast iron's durability means that with proper care, these cooking tools can last a lifetime, often becoming family heirlooms that improve in quality over time.

In the construction sector, foundry cast iron plays a vital role in infrastructure development. Cast iron pipes, for instance, were once the standard for water and sewage systems due to their strength and resistance to corrosion. Despite the advent of modern materials, such as PVC and ductile iron, many cities still rely on cast iron for its longevity and reliability. Furthermore, cast iron's aesthetic appeal makes it a popular choice for architectural features like railings, columns, and ornamental designs.

Environmental considerations are increasingly driving the foundry industry to explore sustainable practices. The recycling of cast iron scrap is common, with melting and re-pouring of used metal being a standard procedure in foundries. This not only reduces waste but also lowers the carbon footprint associated with raw material extraction. As industries continue to prioritize sustainability, the ability to recycle cast iron efficiently positions it as an environmentally friendly option.

In conclusion, foundry cast iron is a remarkable material that has stood the test of time, evolving alongside technological advancements while maintaining its relevance in various sectors. Its excellent casting abilities, thermal conductivity, durability, and aesthetic appeal make it a versatile choice for countless applications. As industries move toward more sustainable practices, the future of foundry cast iron looks bright, promising continued innovation and widespread use in the modern world. Whether in the kitchen, in construction, or in the manufacturing of heavy machinery, cast iron remains a foundational material that contributes to our daily lives and industrial environments.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025