- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 14, 2024 18:20 Back to list

Exploring the Benefits and Applications of Investment Casting in Modern Manufacturing Industries

Investment Casting Parts Factories An Overview

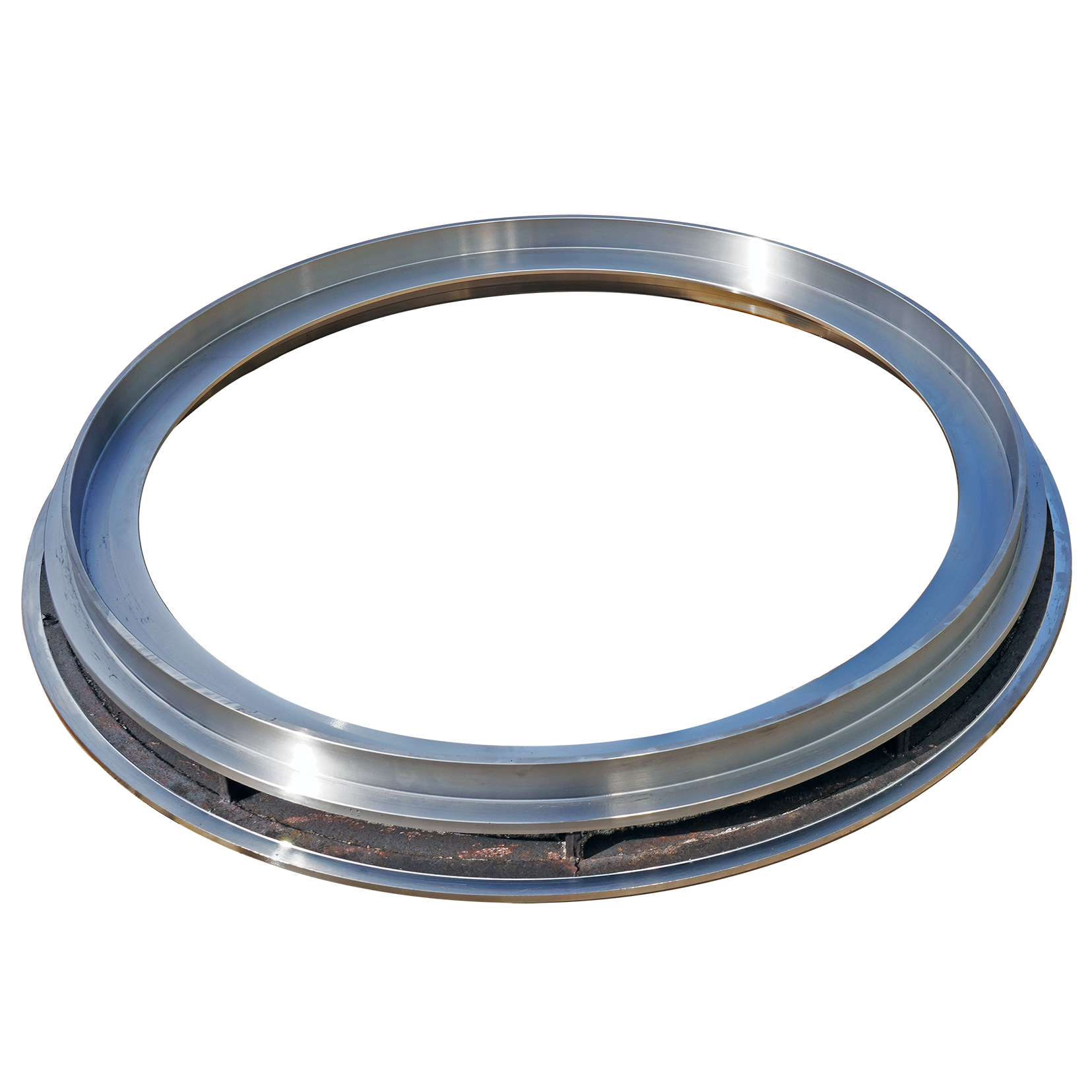

Investment casting, also known as lost-wax casting, is a precision manufacturing process used to create complex metal parts with high dimensional accuracy and superior surface finishes. This method has become increasingly popular across various industries, including aerospace, automotive, medical, and oil and gas, due to its ability to produce intricate components that cannot be achieved through traditional machining. In this article, we will explore the significance of investment casting parts factories, their processes, and their role in modern manufacturing.

The Investment Casting Process

The investment casting process begins with creating a wax pattern of the desired part. This pattern is coated with a ceramic shell, which is then heated to remove the wax and harden the shell, resulting in a mold. Once the mold is prepared, molten metal is poured in, filling the cavity left by the wax pattern. After cooling, the ceramic shell is broken away, revealing the cast part. This method allows for exceptional detail and repeatability, making it ideal for industries that demand high precision.

One of the key advantages of investment casting is its ability to create intricate geometries that would typically be difficult or impossible to achieve with traditional foundry methods. This includes thin-walled sections, complex internal passages, and fine details. Additionally, the process minimizes waste, as the mold can be reused multiple times, contributing to cost-efficiency and sustainability.

Investment Casting Parts Factories

Investment casting parts factories are specialized facilities dedicated to producing components using this sophisticated process. These factories are equipped with advanced technology and equipment, including computer-aided design (CAD) systems, robotic arms for precision handling, and high-temperature furnaces for melting metal.

investment casting parts factories

Moreover, quality control is paramount in these factories. Each stage of production, from pattern creation to final inspection, is meticulously monitored to ensure that the components meet stringent industry standards. Factories often employ non-destructive testing methods to evaluate the integrity of the cast parts, ensuring they can withstand the challenges of their intended applications.

Applications and Industries

Investment casting parts are utilized in a wide range of industries due to their versatility and performance. In the aerospace industry, for example, high-strength components such as turbine blades, brackets, and housings are commonly produced using this method. The automotive sector benefits from investment casting in the production of engine blocks, gear housings, and intricate suspension components that require high durability and precision.

The medical industry also relies on investment casting for creating surgical instruments and implantable devices that require biocompatibility and precision. In the oil and gas sector, investment casting is essential for fabricating valves, pumps, and fittings that can withstand extreme conditions.

Conclusion

Investment casting parts factories play a crucial role in the manufacturing landscape by providing innovative solutions for producing complex and high-quality components. With advancements in technology and an increasing demand for precision parts, these factories are poised to expand further, contributing to the efficiency and effectiveness of modern production processes across various industries. As industries continue to evolve, investment casting will remain a vital component in the quest for superior manufacturing capabilities, ensuring that manufacturers can meet the demanding standards of today's market.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025