- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 31, 2024 21:51 Back to list

Exploring the Innovations and Techniques in China's Casting Industry and Its Global Impact

The Growing Importance of Casting Parts in China's Manufacturing Landscape

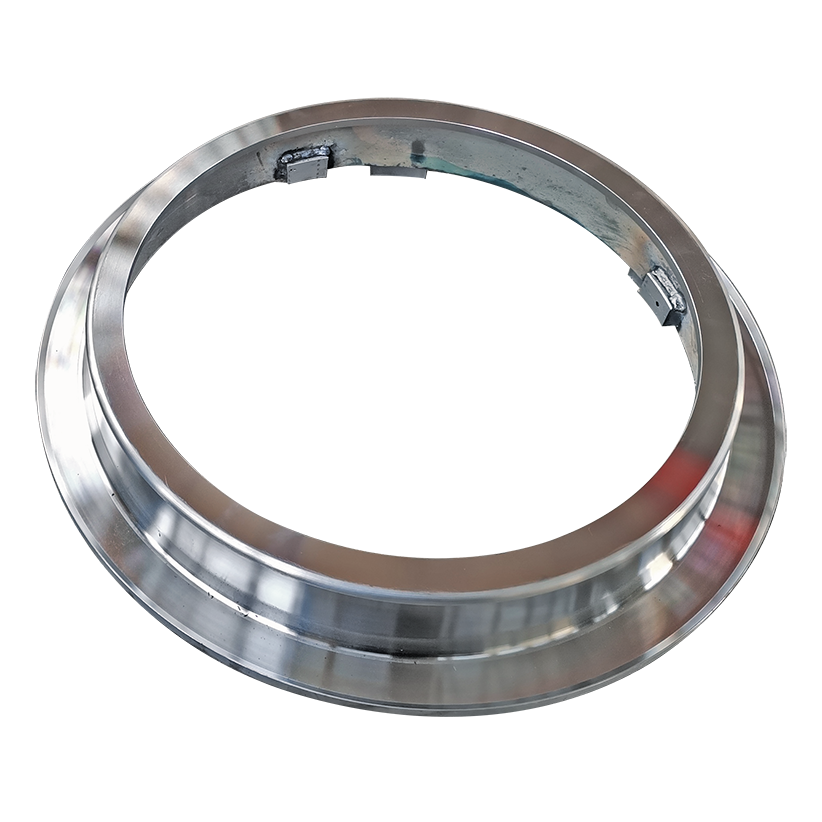

Casting is a critical manufacturing process that allows for the creation of complex shapes and components by pouring liquid material into a mold. In recent years, the casting parts industry in China has experienced remarkable growth, driven by various factors such as industrial advancements, an expanding consumer market, and the country's robust manufacturing sector. This article explores the significance of casting parts in China, highlighting its applications, technological advancements, and future prospects.

One of the primary advantages of casting is its ability to produce intricate designs that would be difficult or impossible to achieve through other manufacturing methods. This is particularly valuable in industries such as automotive, aerospace, and machinery, where precision and durability are paramount. China, being one of the largest automotive producers in the world, relies heavily on casting for components like engine blocks, transmission cases, and structural parts. The automotive sector alone accounts for a substantial portion of the country's casting production, emphasizing the industry's critical role in supporting economic growth.

The Growing Importance of Casting Parts in China's Manufacturing Landscape

Technological advancements are reshaping the casting industry in China, leading to improved efficiency and quality control. The adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has allowed manufacturers to create more precise molds and predict material behavior during the casting process. Additionally, innovations like 3D printing are starting to revolutionize mold making, providing faster turnaround times and reducing material waste. As a result, Chinese foundries are more competitive and capable of delivering high-quality parts that meet international standards.

china casting part

Environmental considerations also play a significant role in shaping the future of casting parts in China. The government has implemented stringent policies aimed at reducing emissions and promoting sustainable practices within the manufacturing sector. Many companies are now investing in eco-friendly technologies and practices, such as recycling scrap metal and utilizing energy-efficient machinery. By adopting sustainable methods, Chinese casting manufacturers can contribute to global efforts to combat climate change while enhancing their market appeal.

The prospects for China’s casting parts industry appear promising. As the country continues to upgrade its manufacturing capabilities and embrace technological advancements, the demand for high-quality casting components is expected to rise. The growing trend of automation and digitalization in manufacturing is likely to enhance productivity and flexibility, allowing companies to respond more effectively to market changes.

Moreover, with the global shift towards electric and hybrid vehicles, as well as the rising demand for renewable energy systems, the casting industry in China is well-positioned to capitalize on these emerging sectors. The ability to produce specialized parts for EV batteries, wind turbines, and solar panel frames underscores the relevance of casting in the transition to a more sustainable future.

In conclusion, casting parts play a vital role in China's manufacturing ecosystem, with applications that span multiple industries. The combination of traditional expertise, modern technology, and an increasing focus on sustainability ensures that the casting industry will continue to thrive in the coming years. As Chinese manufacturers adapt to new challenges and embrace innovative solutions, they will further solidify their position as global leaders in casting part production.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025