- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 15, 2024 17:05 Back to list

Exploring the Innovative Processes of Casting and Parts Manufacturing in Modern Factories

The Importance of Casting Part Factories in Modern Manufacturing

Casting is a pivotal process in the manufacturing industry, playing a crucial role in the production of a diverse range of components that are integral to various sectors, including automotive, aerospace, machinery, and consumer goods. The effectiveness of this process largely depends on the quality of casting part factories, which serve as the backbone of the supply chain for many manufacturers. In this article, we will explore the significance of casting part factories, the techniques they employ, and the future of casting technology.

The Importance of Casting Part Factories in Modern Manufacturing

The modernization of casting part factories has led to significant advancements in technology. State-of-the-art machinery, including computer numerical control (CNC) machines and 3D printing technologies, have enhanced production capabilities. These innovations enable factories to produce intricate designs more efficiently and with reduced waste. Furthermore, automation in the casting process has improved safety and precision, minimizing human error and increasing output rates.

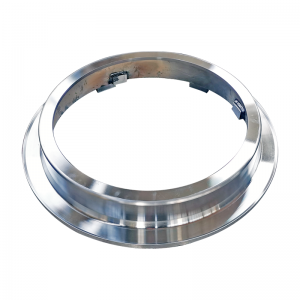

casting part factory

Another vital aspect of casting part factories is their role in sustainability. With growing concerns about environmental impact, many factories are adopting more sustainable practices by recycling materials and utilizing eco-friendly processes. Innovations like the use of water-soluble binders in sand casting minimize harmful emissions, while advancements in energy-efficient furnaces reduce the overall carbon footprint of the manufacturing process. These steps are not only beneficial for the environment but can also lower operational costs, making casting factories more competitive in the global market.

In addition to the technological advancements and sustainability efforts, the expertise of the workforce in casting part factories cannot be overlooked. Skilled labor is essential for operating complex machinery, maintaining quality control, and ensuring that the final products meet stringent industry standards. As such, continuous training and development programs are crucial for sustaining a skilled workforce capable of adapting to ongoing changes in technology and market demands.

The future of casting part factories looks promising, driven by ongoing research and development in materials science and process engineering. The emergence of new alloys and composites is expanding the possibilities for casting applications, allowing for lighter, stronger, and more durable components. Moreover, with the integration of artificial intelligence and the Internet of Things (IoT), factories of the future are expected to become increasingly interconnected, enabling real-time monitoring and optimized production processes.

In conclusion, casting part factories play an indispensable role in the modern manufacturing landscape. They enable the production of complex components that are vital across various industries. The continuous evolution of casting technologies, coupled with sustainability efforts and a skilled workforce, positions these factories to meet the demands of an ever-changing market. As we look ahead, the potential for innovation in casting methodologies will undoubtedly further enhance the capabilities of manufacturing, contributing to a more efficient and sustainable industrial future.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025