- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 10, 2024 04:30 Back to list

Exploring the Leading OEM Polish Pump Case Manufacturing Facilities and Their Impact on the Industry

The Rise of OEM Polish Pump Case Factories An Economic Perspective

In recent years, the demand for high-quality, efficient, and reliable pump systems has surged across various industries, from agriculture to manufacturing. Central to this demand are OEM (Original Equipment Manufacturer) polish pump case factories, which play a critical role in the production and supply chain of these essential components. This article explores the growing significance of OEM polish pump case factories, their contribution to the economy, and the challenges they face.

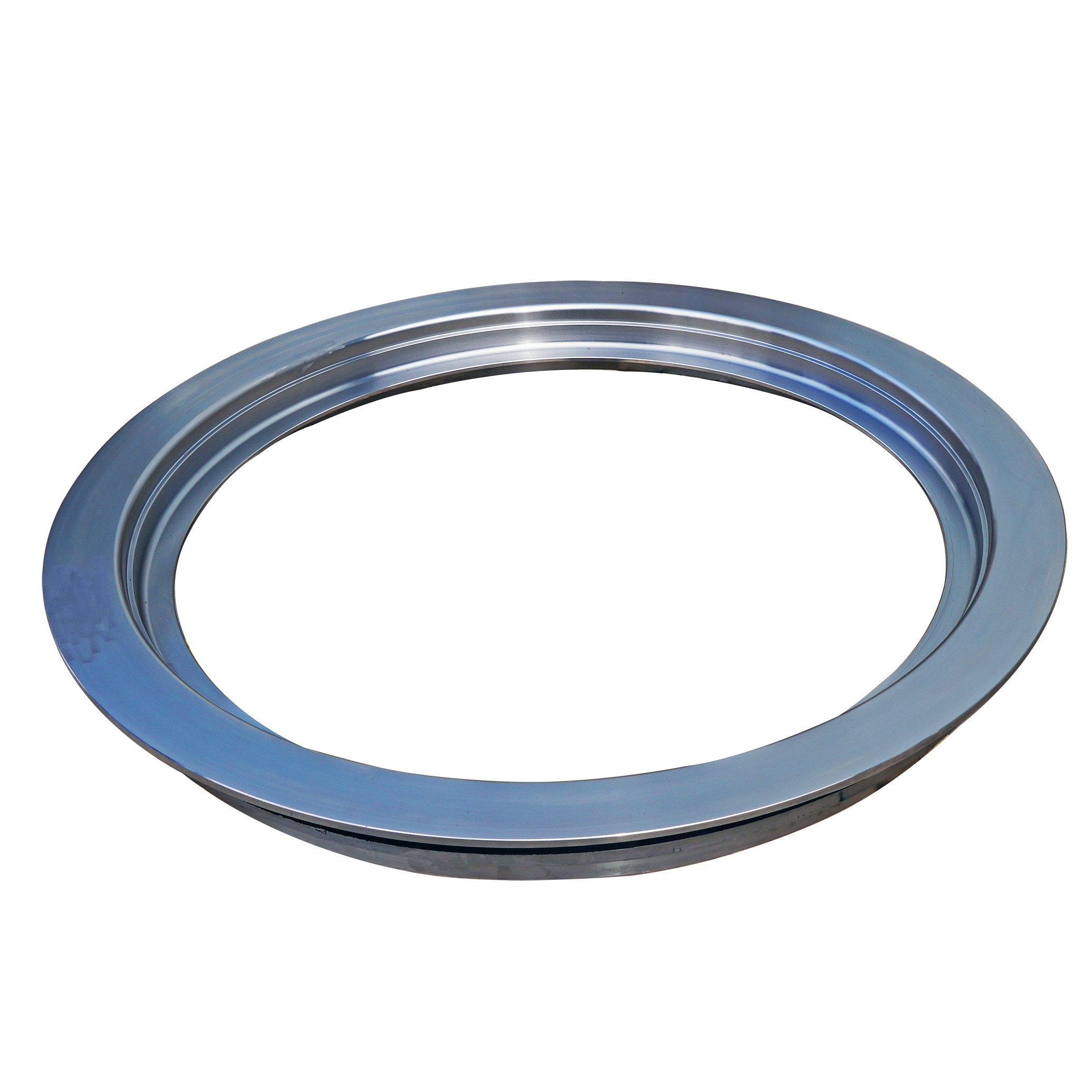

Understanding OEM Polish Pump Cases

OEM polish pump cases refer to the outer casings of pumps that are produced by manufacturers who supply these components directly to other companies, which then assemble and sell the final pump systems. In this context, “polish” denotes both the finishing quality of the cases and the geographical significance of Polish manufacturers, known for their advanced engineering capabilities and high production standards. These cases are crucial for the durability and efficiency of pumps, affecting everything from fluid dynamics to energy consumption.

Economic Contributions

The establishment of OEM polish pump case factories has notable economic implications. Firstly, it drives job creation within local communities. Factories require skilled labor for manufacturing, quality control, and logistics, contributing to employment opportunities and economic stability. Moreover, by fostering a robust supply chain, these factories stimulate ancillary industries, including raw material suppliers, transportation, and technical services, thus enhancing the overall economic ecosystem.

Furthermore, Poland's strategic location in Europe serves as a logistical advantage for OEM factories. This geographical positioning enables companies to efficiently supply not only local markets but also a range of international clients. As globalization weaves tighter connections between economies, Polish manufacturers are increasingly positioned as key players in the global pump market.

Innovation and Technology Advancement

oem polish pump case factories

OEM polish pump case factories are at the forefront of technological innovation. They invest in advanced manufacturing processes such as precision casting, CNC machining, and additive manufacturing (3D printing). These innovations enhance product quality and performance, enabling manufacturers to produce lightweight, corrosion-resistant materials that extend the lifespan of pump systems.

To remain competitive, these factories are also adopting Industry 4.0 practices, which integrate IoT (Internet of Things), big data analytics, and smart manufacturing into their operations. This transition not only streamlines production but also reduces waste, minimizes downtime, and enhances product customization, allowing companies to meet specific client needs.

Challenges Faced by OEM Factories

Despite their growth and potential, OEM polish pump case factories face several challenges. One of the most significant issues is the constant pressure to reduce costs while maintaining high-quality standards. Global competition from lower-cost manufacturing regions poses a constant threat, compelling Polish manufacturers to enhance efficiency while still investing in quality improvement.

Moreover, fluctuations in the global supply chain can disrupt production schedules and lead to delays. The COVID-19 pandemic highlighted the vulnerabilities of supply chains, emphasizing the need for factories to develop more resilient sourcing strategies.

Conclusion

OEM polish pump case factories are crucial components of the global pump industry, offering economic benefits, driving technological advancements, and responding to evolving market demands. As these factories continue to innovate and adapt to challenges, they will play an essential role in shaping the future of pump manufacturing. Their resilience and commitment to quality will ensure they remain competitive players on the global stage, benefiting not only their local economies but also the industries they serve worldwide.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025