- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 08, 2024 03:35 Back to list

Exploring the Relationship Between Factories and Connectivity in Modern Manufacturing Systems

Connecting Factories The Future of Manufacturing

The manufacturing landscape is undergoing a profound transformation, driven by technological advancements and the need for greater efficiency and agility. As companies seek to compete in a rapidly evolving marketplace, the concept of connect factories has emerged as a pivotal strategy. This paradigm involves integrating digital technologies, data analytics, and communication systems to create interconnected manufacturing environments that enhance productivity and responsiveness.

At the heart of the connect factories concept is the rise of Industry 4.0, which represents the fourth industrial revolution characterized by the fusion of digital and physical technologies. The integration of the Internet of Things (IoT), artificial intelligence (AI), big data, and automation is enabling factories to communicate with each other and with various stakeholders, including suppliers and customers. This interconnectedness facilitates real-time data sharing and decision-making, significantly improving operational efficiency.

One of the primary benefits of connecting factories is the ability to streamline operations. Traditional manufacturing processes are often characterized by silos and inefficiencies. By connecting multiple factories and systems, organizations can achieve a holistic view of their operations, allowing them to identify bottlenecks, reduce waste, and optimize resource allocation. Moreover, with advanced analytics, manufacturers can predict maintenance needs, minimize downtime, and enhance overall equipment effectiveness (OEE).

In addition to operational efficiency, connected factories also enhance flexibility and responsiveness to market demands. In today's fast-paced business environment, the ability to adapt quickly to changing consumer preferences is crucial. Connected factories can facilitate agile manufacturing practices, enabling companies to scale production up or down based on real-time demand signals. This flexibility not only helps organizations maintain competitiveness but also reduces the risks associated with overproduction and inventory surplus.

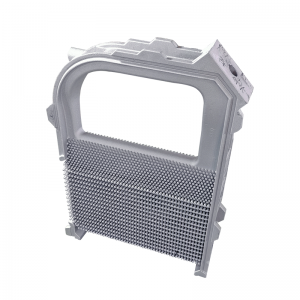

connect factories

Furthermore, connected factories foster innovation by enabling collaboration across various domains. With interconnected systems, manufacturers can share knowledge and best practices, facilitating a culture of continuous improvement. Cross-functional teams can leverage insights from different factories and collaborate on product development, supply chain optimization, and process enhancements. This collaborative environment accelerates innovation and allows companies to bring new products to market faster.

However, the journey towards building connected factories is not without its challenges. Cybersecurity concerns are paramount, as increased connectivity exposes manufacturers to potential data breaches and cyberattacks. Therefore, robust security measures must be implemented to safeguard sensitive information and ensure the integrity of operational technologies. Additionally, the transition to connected factories requires significant investment in infrastructure, training, and change management to ensure all employees are equipped to utilize new technologies effectively.

Moreover, the workforce needs to evolve alongside technological advancements. Future manufacturing jobs will increasingly require a blend of technical skills and problem-solving abilities. Organizations must invest in training and upskilling their employees to navigate the complexities of connected manufacturing environments. This investment not only enhances workforce capabilities but also promotes employee engagement and satisfaction.

In conclusion, the concept of connecting factories represents a significant evolution in the manufacturing sector. By embracing digitalization and interconnected systems, manufacturers can achieve unprecedented levels of efficiency, flexibility, and innovation. While there are challenges to overcome, the potential rewards are substantial. As organizations continue to explore and implement connected factories, the vision of a smarter, more responsive manufacturing ecosystem is becoming a reality, setting the stage for competitive advantage in the years to come.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025